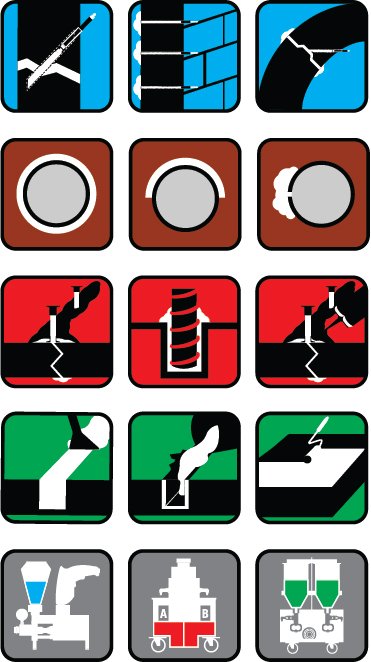

Injectable Waterstop Hose Injection System

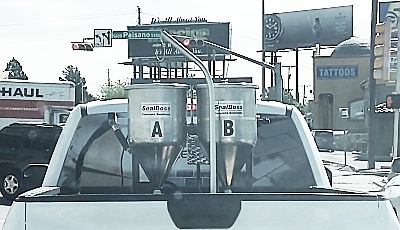

Injectable Waterstop Hose

Injection System

Superior Hose Injection System

SealBoss Injection Hose Advantage

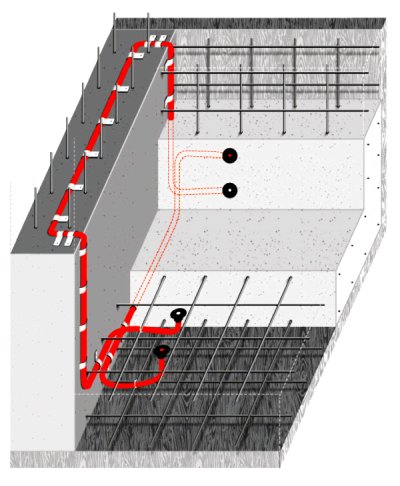

The Inject Tube 2 Hose System is installed in concrete joints to waterproof and seal the cold joint and any cracks or voids in connection with the joint area. The SealBoss Inject Tube System seals joints watertight. The SealBoss Injection Tube Hose System is improving waterstop technology towards a zero leak tolerance. SealBoss Injection Tube is easy to install and priced with a competitive advantage in mind.

Injection Hose Design

The SealBoss Inject Tube System 2 is high quality competitively priced injection hose system with a proven track record. Inject Tube 2 is specially designed with a solid perforated PVC core and covered by two woven membranes to prevent any contamination and clogging of the inner core and to provide for an even distribution of sealant along the cold joint during the injection process.

Injectable Waterstop for Cold Joints & Construction Joints

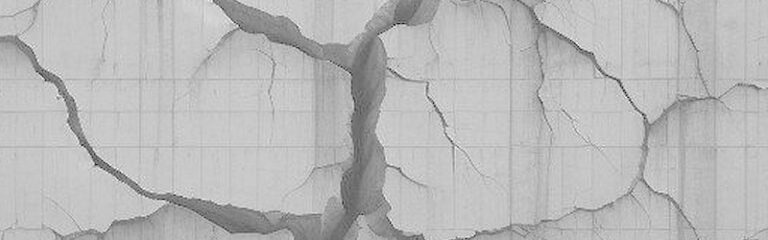

Cold joints and construction joints in concrete structures are vulnerable areas for leaking and cracking due to water penetration. Water ingress can lead to reduced structural integrity and other issues including rebar corrosion and expansion cracks, frost and thaw cycle damages and adverse health effects cause by mold and fungus growth.

What is a Cold Joint?

A cold joint is the area that is created during the concrete pouring process when fresh and existing concrete meet. A cold joint is caused by a lack of bonding / cohesion between the old and new concrete. The cold joint is created when the original batch of concrete has begun to set (or is fully cured) before the next fresh batch is added. The two batches do not form a strong bond and create a passageway for water to migrate.

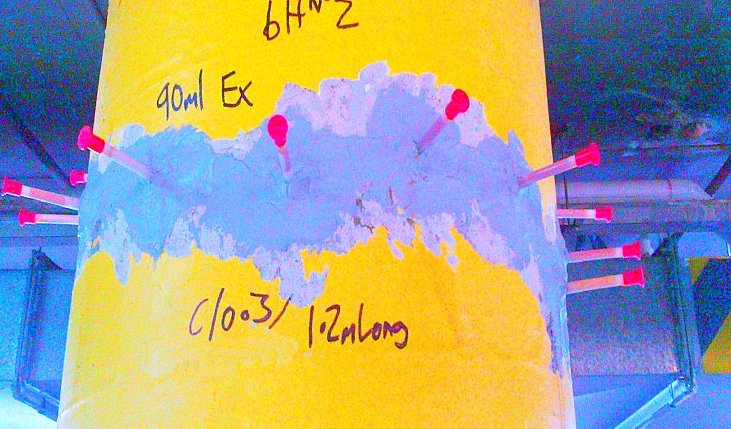

Injection Hose Applications

- Water Stop and Leak-Seal Caulk for Cold Joints / Construction Joints

- Retaining walls

- Foundations

- Slabs on Grade

- Tunnels and culverts

- Dams, Canals

- Pipe penetrations

Injection Hose Application Advantages

- Works on Smooth, Rough, Irregular Concrete Substrates

- Horizontal & Vertical poured-in-place Concrete Joints

- Reliable and Durable

- Retro-fit and New Construction

- Can withstand high Hydrostatic Pressures

- Back-up Solution for Combination with Conventional Waterstops

- Easy to Secure and Install

- InjectTube 1 – Re-Injectable with SealBoss injection acrylate resins

SealBoss Training

- Sealboss on-site training is available to ensure your job gets done right and is successful.

Popular Cold Joint / Construction Joint Water Stop Systems Links