Polymer Pump for Acrylate Gel Injection

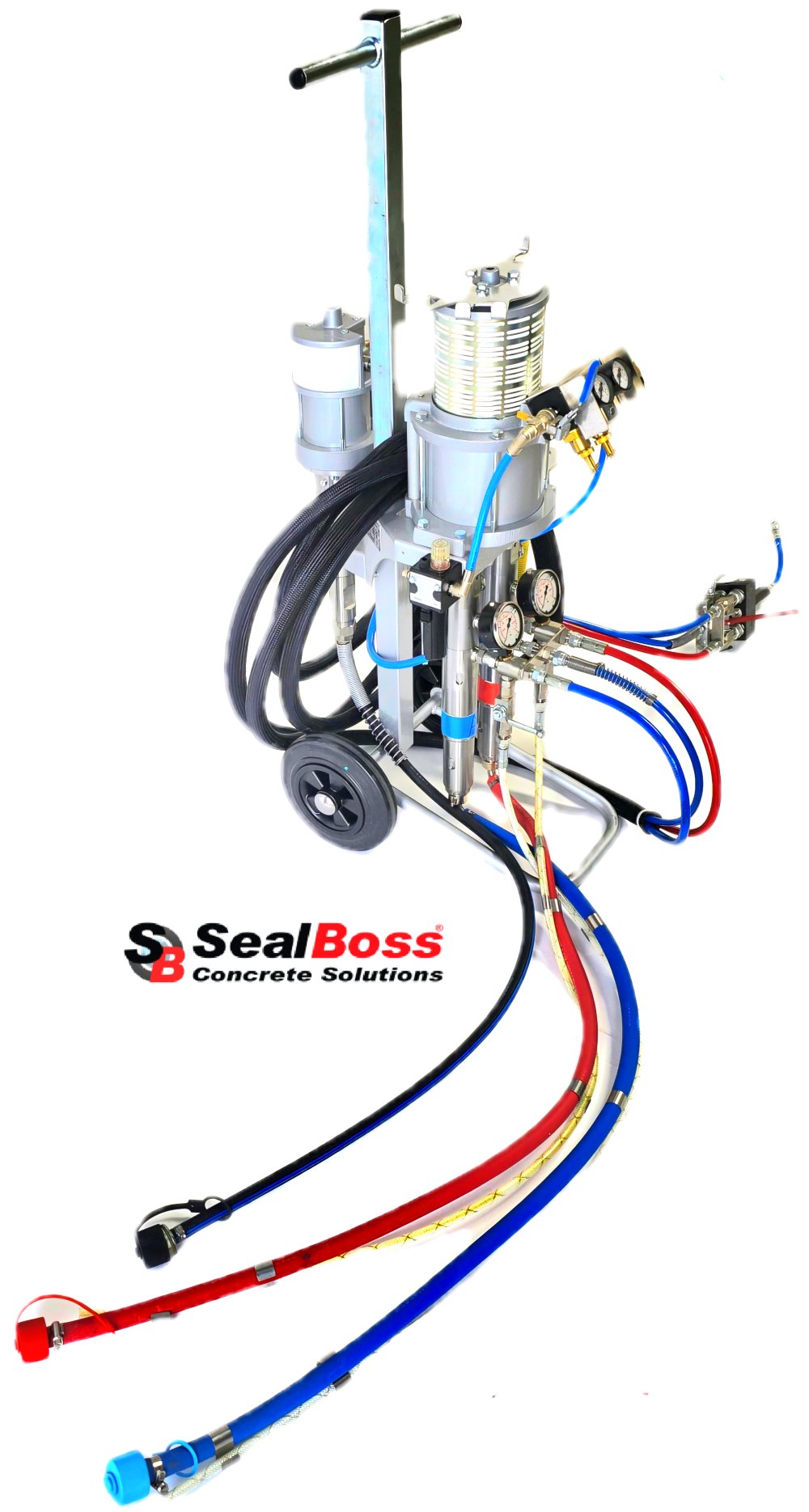

Introducing the New and Enhanced SealBoss® IP2C Generation 2 Gel Injection Pump

A true pioneer in the next generation of acrylate gel injection technology. Crafted with meticulous attention to detail and a relentless commitment to innovation, longevity, and relentless functionality this professional polymer pump sets unprecedented standards in quality, performance, design, and ease of ownership, making it a leader in its class.

The SealBoss® IP2C Gen 2 polymer pump is the epitome of modern engineering excellence, featuring a robust stainless steel pump body construction designed for unmatched durability, precision, and exceptional protection against corrosion. This pump comes equipped with a dedicated water flush pump and is designed for use with acrylate gel injection products.

This polymer pump is not just a tool but a cornerstone of efficient construction and repair work, offering reliability that professionals in the field can trust.

Optimal Compatibility and Use

The SealBoss® IP2C Gen 2 polymer pump is designed to work seamlessly with quality acrylate injection resins and a variety of buttonhead packers, which enhances its compatibility and utility across numerous applications.

We recommend pairing this polymer pump with our SealBoss Super Flexible Acrylate Gels and SealBoss Buttonhead Injection Packers to achieve the best results and performance.

Environmentally Friendly Cleaning with Water when used with Acrylate Injection Gels

Maintaining this polymer pump is straightforward and efficient. For short breaks in the injection process, the mixing head can be flushed using water via the dedicated flush pump, which includes a separate suction tube and flush pressure line. Users can easily switch the applicator handle to flush mode for this purpose.

After completing your injection tasks, it is crucial to perform a thorough cleaning of the entire polymer pump system. Simply place the suction hoses into a tank filled with flushing agent and operate the pump at a lower pressure setting. This cleaning regimen ensures that every component of the polymer pump is free from contaminants and ready for its next use, maintaining the system in optimal condition.

Comprehensive Package and Features

This comprehensive system includes a triple set of 15-foot high-pressure hoses coupled with an equally robust set of suction hoses, ensuring extensive reach and flexibility in various working environments. Each polymer pump component operates independently—two dedicated product component pumps and an independent water pump—culminating in a high-performance mixing head housed within the heavy-duty applicator. This setup ensures precise mixing and application, with a disposable plastic element static mixer that epitomizes ease of use and efficiency.

To prevent any possibility of cross-contamination between components, the polymer pump is equipped with sophisticated built-in check valves. An integrated high-pressure flush pump allows for straightforward cleaning of the mixing chamber through a separate flush line, ensuring that the system remains pristine even when work is momentarily paused.

Advantages of Using SealBoss® IP2C Gen 2 Polymer Pump

- Enhanced Durability and Corrosion Resistance

The stainless steel pump units construction ensures longevity and resistance to corrosion. - High-Performance Mixing and Application

The independent pumping system and state-of-the-art mixing head deliver precise and consistent applications every time. - Ease of Maintenance

With integrated flushing systems and easy-to-follow procedures, maintaining this polymer pump is hassle-free. - Versatility

Suitable for a wide range of environments and applications, from simple repairs to complex construction projects. - Cost-Effectiveness

Minimize waste and maximize efficiency with precise application and reduced need for frequent repairs or replacements.

In Conclusion

The SealBoss® IP2C Gen 2 Gel Injection Polymer Pump is more than just a piece of equipment; it is a vital ally in the construction and repair industries, designed to meet the highest standards and tackle the toughest challenges. Whether you’re sealing foundations, repairing concrete, or handling intricate waterproofing projects, this polymer pump promises performance that professionals can depend on. Embrace the future of construction and repair with SealBoss® IP2C Gen 2, the ultimate polymer pump for your acrylate gel injection needs.

SealBoss 2400 Gel Injection System

Links to Leak Sealing with SealBoss Acrylate/Acrylic Super Low Injection System