10 Minute Concrete Floor Crack Mender & Spall Repair

Ultra Fast Concrete Crack Mender and Spall Repair Resin

Discover the cutting-edge advancements in concrete repair technology. Presenting our lightning-speed, durable, and efficient crack mender and spall repair resin.

Whether it’s reviving floors in bustling warehouses, busy parking facilities, or any structure requiring steadfast and enduring repairs, do it with unprecedented efficiency.

But that’s not all! This multi-purpose resin is also your solution for quick asphalt road fixes.

Want a safe, non-slip finish? Simply integrate our recommended sand aggregate.

Concrete Confidence: Experience Restoration Mastery in Moments!

This Structural Polyurethane is an advanced material that addresses the challenges faced in repairing damaged concrete. Its unique characteristics and properties make it an ideal solution for various applications and environments.

The material’s low surface tension and viscosity allow for easy and complete saturation bonding of cracks, requiring only minimal preparation to remove loose debris.

When the material is allowed to gravity-flow to the full depth of the crack, the repair is considered structural.

Manufactured sand or quartz can be introduced into the repair process and added at a ratio of up to two parts sand to one part mixed polyurethane during crack filling to extend the material’s coverage and enhance its strength. SealBoss 6060 is highly versatile and can be applied over a wide range of substrate temperatures, making it suitable for use in frozen and cold storage warehouse applications or cold weather applications. After the repair is completed, the surface is can be ready to accept traffic in as little as ten minutes at 72°F (22°C), ensuring minimal disruption.

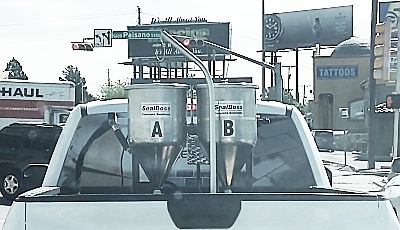

SealBoss 6060 QuickFix is Your Fast Concrete Floor and Road Repair System

SealBoss 6060 is a super low viscosity, fast setting two component polyurethane concrete crack mender offering outstanding penetration properties, superior strength and durability.

At a mixing ratio of 1 to 1 by volume, the mixed product can be used neat or mixed with a sand aggregate to create a quick repair mortar. The product is cured chemically and does not need any moisture to react.

10 Minute Concrete Floor Crack Mender & Spall Repair

- Very Fast Cure

- Short Turnaround Time

- Very Low Viscosity

- Creates Repair Mortar with Dried / Silica Sand

- Super Strong Polyurethane Formula

- Outstanding Bond Strength & Penetration Properties

- Use In Combination With SealBoss 6500 Polyurea Joint Fillers

- Products is available in Cartridges

In Conclusion

The ability of SealBoss 6060 to penetrate deeply into cracks and bond directly to the concrete-aggregate matrix ensures long-lasting and reliable repair.

Structural Polyurethane is adaptable for use in extreme temperature conditions, making it suitable for a range of industries and applications where traditional repair materials might fail.

The rapid curing time of SB 6060 minimizes downtime and disruptions, allowing for swift resumption of normal activities in the repaired area.

Given the material’s versatile nature, it can be used to address a wide variety of concrete damage, including cracks, spalls, and other structural defects.

The compatibility of SealBoss 6060 with Portland Cement Concrete (PCC) enables a smooth blending with pre-existing concrete structures, minimizing the aesthetic effects of repairs.

By incorporating SealBoss 6060 Structural Polyurethane into the repair process, professionals can effectively extend the service life of concrete structures while maintaining their appearance and structural integrity. This innovative material offers a highly effective, efficient, and durable solution for restoring distressed concrete and ensuring its longevity.

10 Minute Concrete Floor Crack Mender & Spall Repair Related Articles

- SealBoss 6060 Floor Repair System

- SealBoss 6060 Road Repair

- Private Road Repair with SB 6060

- SealBoss Cartridge System

Learn More

Feel free to reach out to us at 714-662-4445 for any inquiries, or submit a contact request here. We are eager to assist you in finding the right solution. Expert technical representatives are available to provide on-site support upon request.