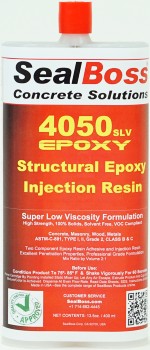

SealBoss 4050 SLV

Hi-Mod SLV Epoxy Resin

Super Low Viscosity High Strength, High Modulus, Epoxy Injection Resin Adhesive

SealBoss ® 4050 Applications

- Structural Concrete Crack Injection

- Welding Cracked Concrete Segments

- Delaminated Slab Repair

- Natural Rock, Masonry, Concrete, Wood

- Gravity Feed or Pressure Injection of Cracks in Concrete, Masonry, Rock, Wood, etc.

- Seal Interior Slabs and Exterior Above-Grade Slabs

SealBoss ® 4050 Advantages

- SealBoss ® Product-Pump-Packer System Solution

- Super Low Viscosity, Deep Penetration Formula

- Convenient Easy Mix Ratio A:B = 2:1 by Volume

- Advanced Flow, Solvent Free Formulation

- VOC Free

- This Product is for Professional Use

SealBoss 4050 SLV Epoxy Resin is a super low viscosity, 100% solids, hi-mod, 2-component, moisture-tolerant, high strength, multipurpose, epoxy injection resin adhesive.

SealBoss 4050 SLV Epoxy Resin meets ASTM C-881/ AASHTO

M-235, Types IV, V, Classes B and C, Grade 1.

Ask your SealBoss Technician for details. The product is for professional use.

Installation Guidelines

SealBoss 4050 SLV Epoxy Resin is composed of two components. The mixing ratio by volume is 2:1 (A:B).

Concrete Crack Injection

SealBoss 4050 SLV Epoxy Resin is suited for the injection of cracks, voids and fissures in concrete, delaminations in concrete, masonry, stone and sealed wood. The very low viscosity of the material provides for superior penetration at low to medium injection pressures. SealBoss 4050 SLV Epoxy Resin bonds well under pressure and offers high tensile and compressive strength properties for structural repairs. The product cures to a tough, resilient polymer with excellent load transfer capabilities. Injection can be performed in wet environments. Best results and highest strengths are achieved in dry conditions. Do not modify the product if used for injection. For best results, epoxy injection must only be performed with approved two component injection equipment. SealBoss provides tested and proven two component injection pumps and accessories.

First prepare the surfaces adjacent to the cracks to expose clean, sound concrete. The injection ports should be spaced from 4 in. (10 cm) to 12 in. (30 cm) apart depending on the crack width and the thickness of the member to be injected. Crack should be sealed at the surface with SealBoss 4500 F QuickSeal Epoxy Paste.

Other Applications

Surface Preparation Surface must be clean and sound. It may be dry or damp, but free of standing water. Remove dust, grease, curing compounds, impregnations, oils and any other contaminants. Preparation Work: Concrete – Should be cleaned and prepared to achieve a laitance and contaminant free, open textured surface by blast cleaning or equivalent mechanical means. Steel – Should be cleaned and prepared thoroughly by blast cleaning or other equivalent mechanical means.

Minimum substrate and ambient temperature 37°F (3.8°C). Do not thin. Material is a vapor barrier after cure. Not for injection of cracks under hydrostatic pressure at the time of application. Do not inject cracks greater than 1/4 in. (6 mm) without consulting Technical Service. Do not add solvents or otherwise thin this material. Color may alter due to variations in lighting and/or UV exposure.

Chemical Resistance

SealBoss 4050 SLV has excellent resistance to a wide range of chemicals including acids and bases, aircraft and automotive fluids, petroleum fuels, cutting oils, etc. It has limited resistance to hydrocarbon solvents. Performance is a function of the specific chemical and concentration, ambient and solution temperatures, and exposure times.