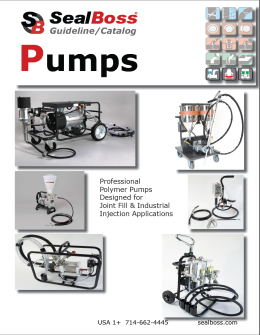

IP2C Premium Acrylate Gel Injection Pump

Stainless Steel Pneumatic Gel Injection Pump

SealBoss ® IP2C Gel Injection Pump Features

- 3 Pump Units | 2 Product / 1 Water

- Stainless Steel Pumps & Applicator

- Sophisticated Design, Simple Operation

- Heavy Duty / High Reliability

- 3000 PSI

- 1:1 Mix Ratio

- High Metering Accuracy

- Separate Flush Pump

- Pressure Lines Included

- Easy To Use / Clean

Range of Applicable Materials

- Polyacrylate gel

- Polyurethane resin

- Polyurethane foam grout

- Aqueous solution

Range of Applicable Materials

- Acrylate Gel / Acrylic Injection Gel

Product Description

The SealBoss ® IP2C Gel Injection Pump sets new standards for performance, design and features. This complete package includes the stainless steel applicator with static mixer, a 15′ triple set of high pressure hoses, triple set of suction hoses. The individual components are pumped separately and mixed in the mix head of the applicator while pumped through a plastic disposable element. Check valves prevent the components from cross contamination.

An integrated high-pressure flush pump is built in for cleaning the mixing chamber via a separate flush line any time work is interrupted. We supply buttonhead packers in several sizes and designs to work with this very strong and reliable injection pump.

Super Flexible Acrylate Gels are the recommended product for use with this pump.

Cleaning Procedure For Use With Acrylate Gel. For short breaks during the injection process the mix head can be flushed with water or flushing agent with the separate flush pump (separate suction tube and flush pressure line). The applicator handle has to be placed in flush mode.

After completion of injection the hole pump system needs to be flushed. Place the suction hoses into the flushing agent tank and rinse all hoses thoroughly by operating the pump at lower pressure setting.