Injection Tube System

Injection Tube System / Injection Hose System

What is the Injection Tube System?

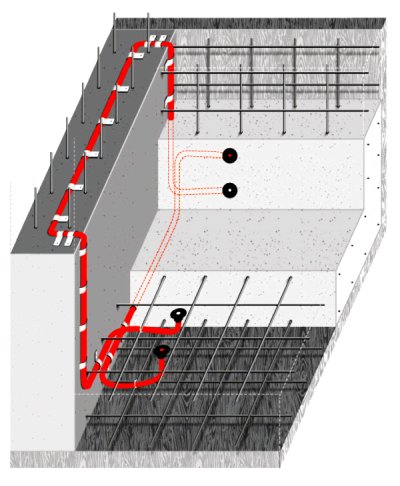

Injection Tube System is a grout delivery system, meant to seal cold and construction joints, mainly in new construction where fresh concrete or shotcrete is applied. In order to connect with already cured concrete structures, creating a cold joint. When installed prior to pouring the concrete, the injection tube permits the injection and delivery of resins & grouts into the cold joint to provide an instant and permanent seal.

The SealBoss Injection Tube System is designed around a solid core, perforated PVC Tube.

The Injection Tube is installed in joints prior to the pouring of new concrete to waterproof and seal any cracks or voids, that may be present. The SealBoss Injection Tube System enables a permanent watertight joints seals.

Easy to install and reasonably priced – The SealBoss Injection Tube System simplifies the job and provides for watertight joints.

SealBoss Injection Tube Type 2 offers a double woven membrane to best protect the inner tube space from water and debris. A clean inner tube assures the best results.

For applications where a re-inject able system is required, SealBoss Inject Tube System is used in combination with SealBoss ® 2400 Acrylate Gel as the Inject Tube system can be flushed with water prior to and after the products set. The system is also compatible with micro-fine cement injections.

SealBoss Injection Tube Advantages

- SealBoss Injection Tube Type 1 and Type 2 to suit specifications & application requirements

- SealBoss ® Injection Tube Type 2 – Double membrane protects tube best from infiltration

- Deep penetration water stop seal

- Will not fold or crush with concrete weight

- Can be injected under flowing water

- NSF potable water applications possibles

Applications

- Cold Joints.

- Expansion Joints.

- New and Retrofit Construction

- Tunnels, Parking Garages, Slurry Walls, Pipe Joints

The SealBoss Injection Tube System is an efficient and easy to install system to create water tight cold joints

A well-known characteristic of concrete is shrinkage while curing. Stress caused during this time and temperature changes provoke the development of small cracks and fissures.

Several design and reinforcement techniques help to control this effect, but cannot control them completely. Fine cracks of sometimes less than 0.1 mm are inevitable. These cracks are considered normal and generally do not cause any problems. However, at cold joints, the tendency to form larger cracks cannot be reduced.

Since old and new concrete do not bond together homogeneously and do not form a monolithic concrete body, stress cracks concentrate mainly in these areas. They easily conduct water and may cause severe damage.

The SealBoss Injection Tube System for sealing cold joints utilizes the natural tendency of concrete to form cracks. A special tube system is installed at the joint where leaks are most likely to occur. The system allows resin injection directly into the joint through a protected porous tube after completion of the structure. The resin penetrates through the perforation of the tube and fills the cracks and voids of the cold joint area thereby sealing the structure.

To be effective, the system must have certain properties. The tube must be sturdy enough to withstand the high pressure of placed concrete and it must resist concrete slurry penetration. On the other hand the injection resin must be able to penetrate the hose at a moderate injection pressure. The installation and injection process must be suitable for construction sites. The SealBoss Injection Tube System is designed to meet these requirements.

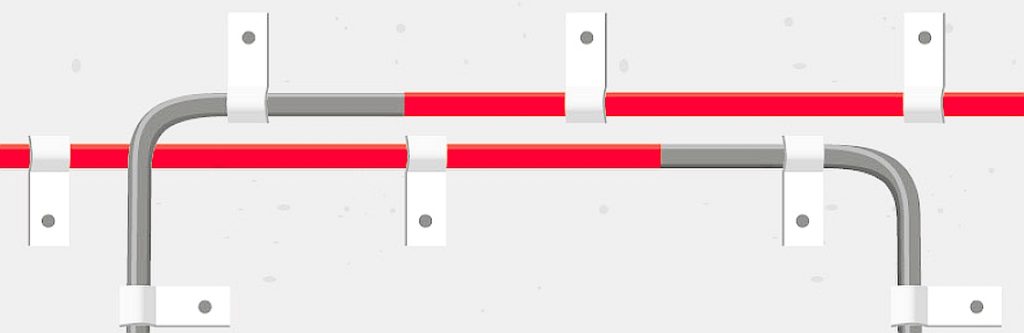

Before pouring the new concrete the tube shall be attached to the existing surface as tight as possible and usually towards the middle of the future cold joint using suitable clips or by attaching it to the existing rebars. It is crucial that the hose is tightly fixed in the center of the joint area so that it can neither move nor lift during the concrete placement. Six to twelve inches between clips are typically recommended.

The hose must be placed in a manner that it will not touch the outside surface of the structure at any point. To allow sufficient injection pressures, the maximum length of injection tube should not exceed 30 feet.