Cold Joint Water Stop Systems

In the world of construction, managing water intrusion at cold joints presents a significant challenge. SealBoss, a pioneer in construction technology, introduces an innovative range of waterstop solutions tailored for new construction projects. These products, including hydrophilic swellable caulk and tape, as well as the innovative SealBoss Inject Tube, are designed to provide quick, effective, and reliable cold joint sealing, ensuring structural integrity and durability.

Swell Tape Swell Tape: A Robust Hydrophilic Solution

SealBoss Swell Tape stands at the forefront of hydro active, swellable water stop technology. This manufactured hydrophilic strip swells upon contact with water, creating a robust compression seal. Ideal for sealing construction joints, pipe penetrations, and various concrete interfaces, the Swell Tape is strategically applied at the center of the existing cured concrete surface before a new pour. Crafted for professional use, this product exemplifies SealBoss’s commitment to quality and effectiveness in sealing solutions.

SwellCaulk: Versatile and Efficient Water Stop

SealBoss Swell Caulk is a single-component, gun-grade water stop solution, designed to adeptly handle the challenges of sealing construction joints and pipe penetrations on both smooth and uneven surfaces. When exposed to moisture or water, this hydrophilic material cures and swells, creating a secure compression seal. The curing time, typically ranging from 24 to 36 hours, is influenced by ambient climate conditions.

Available in sausages or cartridges, Swell Caulk can also serve as an adhesive for the Swell Tape, offering a comprehensive joint water stop system.

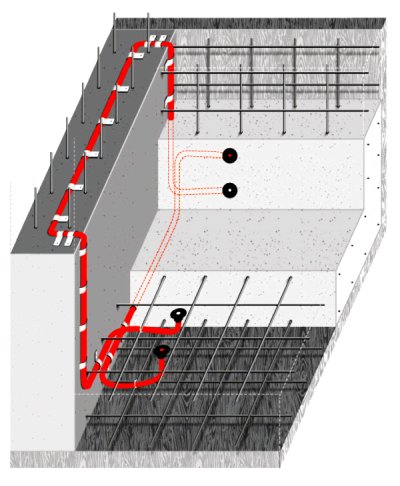

Injection Tube Systems: Advanced Sealing Technology

SB Injection Tube

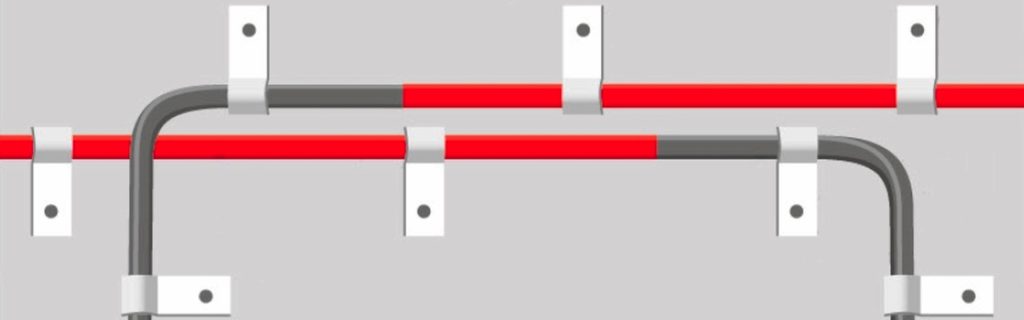

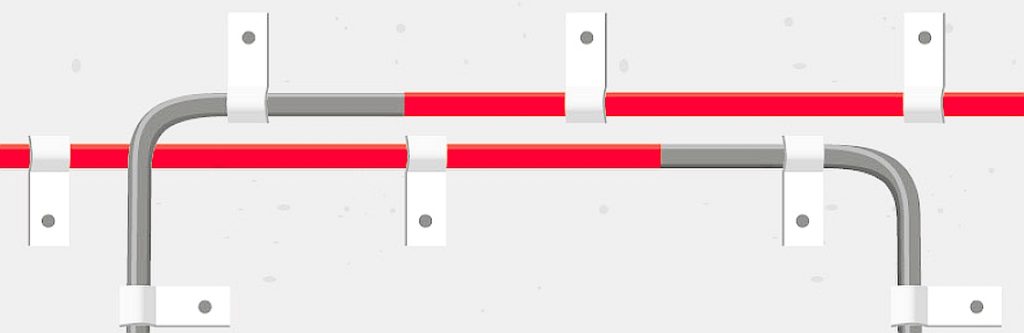

The SealBoss Injection Tube represents a leap forward in injection technology. Compatible with all SealBoss injection foams, gels, and resins, it features a perforated PVC inner tube, designed to withstand the pressures of freshly placed concrete. The tube is covered woven membranes, serving a dual purpose: preventing the entry of cement particles and mitigating the abrasive effects of concrete aggregates. This system is an epitome of durability and effectiveness in modern construction practices.

SB Injection Tube 2 – Building on the success of its predecessor, the SealBoss Injection Tube 2 incorporates an additional layer of protection with two woven membranes.

This design enhances its capability to shield the inner tube from cement particles and the abrasive nature of concrete aggregates. Compatible with a wide range of SealBoss products, the Injection Tube 2 is a testament to the company’s dedication to innovative and resilient construction solutions.

Conclusion

SealBoss’s range of cold joint water stop systems exemplifies the blend of innovation and practicality in modern construction.

These products not only offer effective solutions for water intrusion at cold joints but also embody the commitment to providing durable, reliable, and user-friendly products. As the construction industry evolves, SealBoss continues to lead the way in developing technology that addresses the ever-changing challenges of the field.

Injection Tube Type 2

Injection Tube Type 2