What is an Injection Tube?

Injection Tube Systems – a.k.a. Injection Hose Systems – are used for sealing structural joints and cold joints in below-grade concrete structures such as tunnels, tanks and parking garages. Cold joints form when new concrete is poured on an already existing cured concrete substrate.

SealBoss Injection Tube acts as a delivery system for injection resins and grouts, to travel into the concrete joints and matrix’s, sealing joints, cracks, voids and honeycombs in the process.

If left untreated, cold joints in concrete structures enable water migration driven by hydrostatic pressure – leading to concrete deterioration, rebar corrosion, and further infrastructure damage.

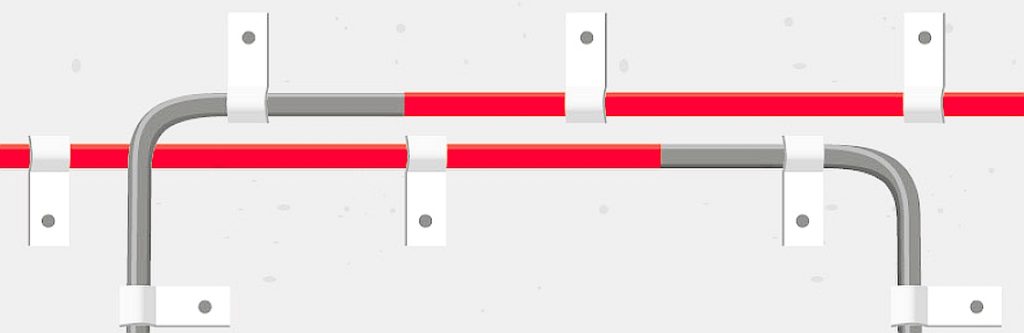

The SealBoss Injection Tube Type 2 is constructed from a specially formulated perforated plastic core tube and two independent woven membranes, in order to prevent the infiltration of concrete particles and contaminated water, during and after the concrete pour. Under pressure injection, the woven membranes provide for an even distribution of injection resin along the tube and into the cold joint. The flexible nature of the Inject Tube allows it to follow uneven substrates and corners.

The Injection Tube Type 2 System is an essential product for creating water tight cold joints in poured concrete structures.

Each new pour of concrete onto existing concrete creates a joint of low cohesion called a cold joint. Additionally shrinkage of the concrete causes added stress, which given enough time can crack and erode due to fluctuations in weather and temperature.

The installation of the SealBoss Injection Tube Primary Water Stop System and subsequent injection with SealBoss Resin, creates a monolithic seal in cold joints while penetrating into fine cracks and fissures. Thus preventing any future migration of water.

Applications

- Cold Joints

- Expansion Joints

- Structural Joints

- Replacement for Traditional PVC Water Stops Systems

- Primary Waterstop System

Advantages

- Economic Water Stop System

- Simple installation

- Compatible with a Variety of Injection Resins

- Creates a Monolithic Water Stop Seal

- Potable Water Applications with NSF Certified Injection Grout

- Works with Honeycomb and Uneven Concrete Substrates

- Tolerates Height Concrete Weight

- Injection Dry or Under Flowing water

- Good Chemical Resistance

- Repeated Injection Possible

Injection Tube / Injection Hose System Type 2 Water Stop

Please don’t hesitate to contact us here at Sealboss for more information about our extensive injection equipment and accessory selection. Your representative will be happy to assist. We provide on-site support and training for all SealBoss System Solutions.

Please ask for your technical sales representative when you call – we are ready to help!