Midwest Joint Fill Training | SealBoss 6500 Polyurea & JointMaster Pump

Midwest Joint Fill Training

SealBoss 6500 Polyurea & JointMaster Pump

Another

On the Job Training

Joint Fill & Repair

Heartland Warehouse Renovation

Introduction:

This article explores the training and application of SealBoss 6500 Polyurea Joint Filler and JointMaster Pro2 Pump in an aerospace facility renovation, emphasizing the importance of proper floor joint repair in industrial settings.

Focusing on a case study from St. Louis, Missouri, we highlight how a local contractor, new to joint filling, received hands-on training from a SealBoss Technical Representative.

The project involved repairing 6,000 linear feet of floor joints to meet the demands of a high-profile aerospace company, showcasing the effectiveness of professional training and high-quality materials in preparing warehouses for heavy-duty use.

Aerospace Facility Floor Joint Fill and Repair with SealBoss 6500 Polyurea Joint Filler and JointMaster Pro2 Joint Filling Pump

With development of building tilt-up warehouses on the rise across the country, many are not quite suited for the new lessee and required renovations and improvements, as they must be made prior to moving in and the beginning of operations.

SealBoss Expertise Elevates Industrial Floor Solutions

On-Site Expertise from SealBoss

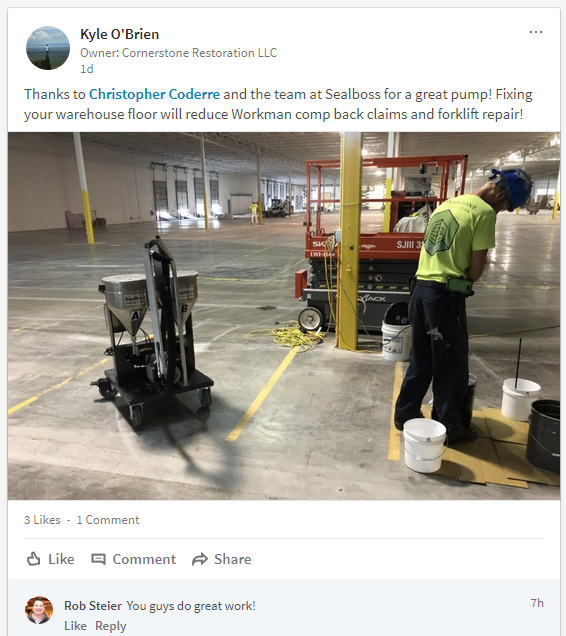

In the bustling heart of St. Louis, Missouri, a SealBoss Technical Representative was summoned to impart specialized training on the SealBoss Floor Repair Systems to a local contracting team. This professional enrichment was tailored to equip the team with the requisite skills for executing imperative renovations, facilitating the seamless transition for an esteemed lessee’s occupancy.

Catering to a High-Profile Client with Superior Products

The project was commissioned by a renowned Aerospace company, necessitating the warehouse to be adept at handling and storing hefty aerospace components. In response to the rigorous demands of such a high-caliber client, the SealBoss 6500 heavy-duty, fast-cure polyurea joint filler was selected. This premium product, boasting an A 80 Shore hardness coupled with 200% elongation, was strategically chosen to ensure seamless navigation of heavy forklift traffic throughout the facility, thereby maintaining operational fluidity.

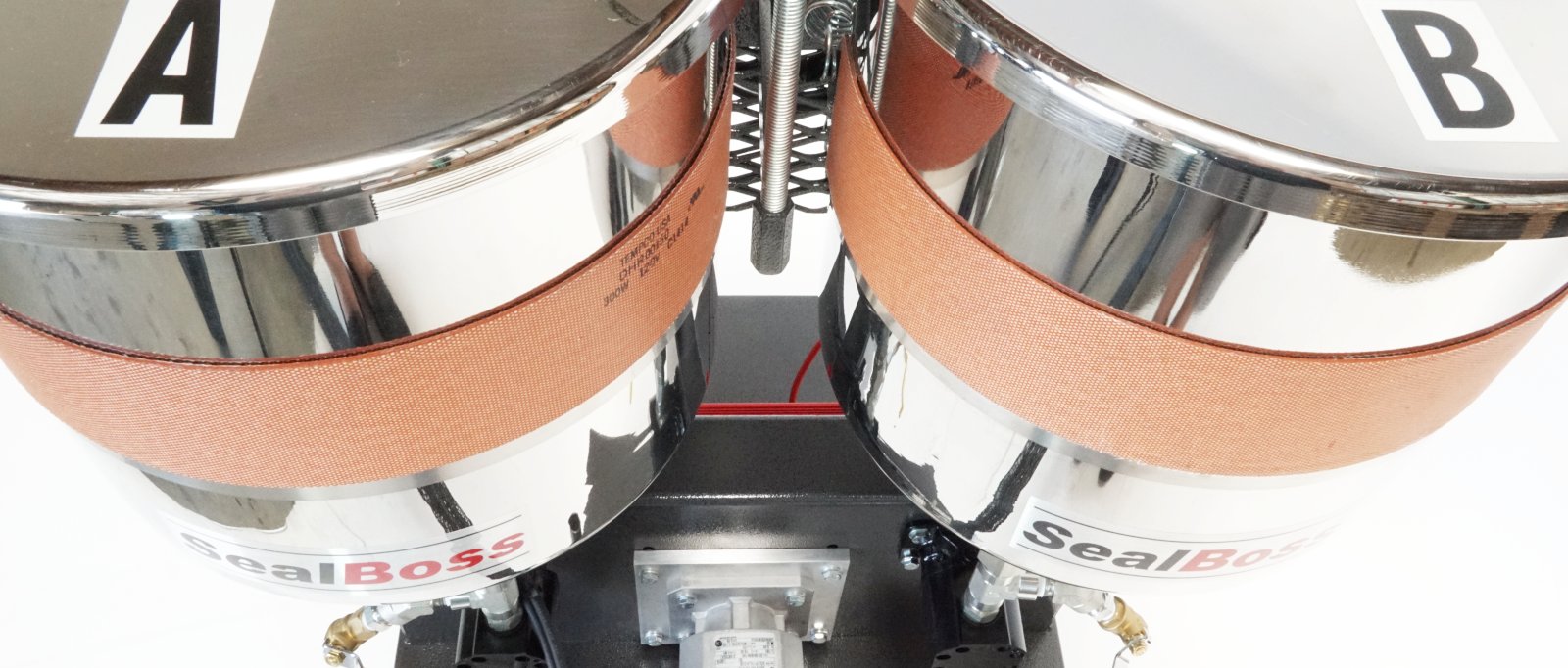

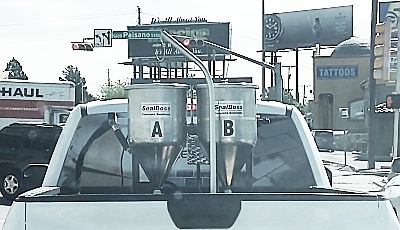

Innovative Technology: The JointMaster Pro2 Joint Fill Pump

The project team, albeit inexperienced with joint filler technologies and the sophisticated JointMaster Pro2 professional battery-equipped dispensing pump, received comprehensive training from the seasoned SealBoss representative. This hands-on educational approach facilitated a swift acclimation to the cutting-edge equipment, ensuring the crew was well-prepared to tackle the task ahead with confidence.

Project Scope and Ambitions

The undertaking involved the meticulous repair and filling of approximately 6,000 linear feet of floor joints within the warehouse. The ambitious goal was set to accomplish this extensive joint fill within a single day, a testament to the efficiency and effectiveness of SealBoss solutions.

Meticulous Preparation for Optimal Outcomes

Preparatory actions were meticulously carried out the day prior to the main operation. The contractor diligently removed any failing joint fill, addressing adhesion and delamination issues to ensure a clean slate. The joints were then methodically cleaned and outfitted with backer rod to the required depth, setting the stage for an optimal repair process.

Strategic Team Composition for Enhanced Efficiency

A strategic three-man crew configuration was recommended to streamline the workflow: one individual to operate the pump, another to precisely apply the SealBoss 6500 polyurea joint fill, and a third ‘floater’ tasked with shaving the joints within the critical 8-15 minute window and replenishing materials as needed. This efficient division of labor was designed to maximize productivity and ensure a smooth execution of tasks.

Empowering Training Leads to Remarkable Results

Following a succinct yet thorough briefing covering the materials, pump operation, and cleaning procedures, coupled with a brief but intensive 20-minute hands-on training session, the novice crew rapidly adapted to the demands of the project. Achieving an impressive dispensing rate of over half a gallon per minute, the team successfully filled and shaved 6,000 linear feet of joints during the training day, a remarkable feat demonstrating the transformative power of expert guidance and high-quality SealBoss products.

“We Provide Field Service When You Need It!

We have been offering experienced and responsive technical support since 1988. While providing on-site support and training, we create a positive learning environment focusing on building applicator confidence allowing for successful repairs to be continued after the training. From training new companies and their employees, SealBoss has continued to provide support to our clients for over 36 years.

On-site training consists of an overview of products, the pump and it’s features. This is followed by hands on training with actual dispensing of material on the job site until the applicator has gotten confident with the application techniques and nuances of the material used. Finally we focus on the correct cleaning procedure of the equipment.

We won’t leave a jobsite till I know everyone is comfortable with the systems and can reteach the next person in line.

With a knowledgeable technical support team, we are here to help with any questions you may have.”