Below Grade Waterproofing

Below Grade Waterproofing: Innovative Solutions for Complex Challenges

In the realm of construction and building maintenance, below grade waterproofing presents a unique set of challenges, especially when dealing with sensitive areas where direct access to the area of leakage is restricted and standard waterproofing crack injection methods cannot be applied.

A recent case involving a below grade mechanical room with water intrusion issues highlights the innovative approaches and solutions available in today’s construction industry.

Polyurethane Polymer Gel and Foam Injection are effective methods to seal areas that are not easily accessible. With direct and indirect chemical grout delivery methods available, a wide array of below grade waterproofing problems can be resolved.

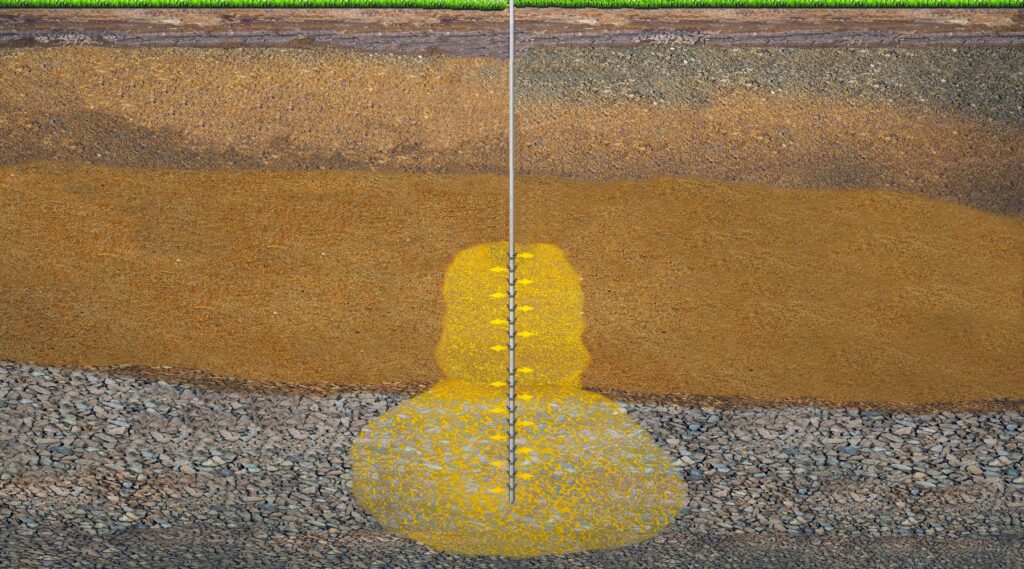

In this specific case grout injection lances were the delivery method of choice to combine waterproofing techniques such as soil permeation and consolidation grouting and curtain injection grouting to seal a subterranean mechanical room of a hospital.

Below Grade Waterproofing

Using Injection Lances and Polymer Gel

The Challenge: Water Intrusion in a Below Grade Mechanical Room

A mechanical room located below grade was experiencing water intrusion through shrinkage cracks and cold joints. The complexity of the situation was heightened by the fact that the problem could not be addressed from the negative side (inside the mechanical room) due to the placement of conduit and utility pipes. This scenario is not uncommon in below grade waterproofing projects, where access and space constraints often limit traditional repair methods.

Seeking Expert Solutions

In response to this challenge, the engineer overseeing the project reached out to SealBoss, a renowned name in the field of waterproofing and chemical grout injection solutions. SealBoss proposed a soil permeation and consolidation grouting and curtain injection grouting solution using SealBoss FlexGel hydrophilic polyurethane polymer leak sealing foam gel, a method well suited for this complex below grade waterproofing scenario.

The Process – Soil Permeation Injection and Consolidation Grouting with Injection Lances

Once the proposal was approved by all parties involved, the injection process began. The first step involved drilling cores to confirm the layout of below grade structures. During this phase, an unexpected utility bay was discovered, necessitating a modification in the layout of injection points to accommodate these below grade structures.

Installation and Injection Techniques

The installation process involved driving ½” soil injection lances into the core holes and installing female couplers to work with the custom applicator built by the contractor.

This step was crucial for ensuring that the SealBoss FlexGel would be injected precisely where needed. Before the injection of FlexGel, each hole was initially flooded with water using a SealBoss IP495 Pump, specifically dedicated for water injection. This flooding was essential to suspend the strata below and prepare it for the FlexGel injection.

FlexGel Injection: Creating a Waterproof Barrier

Each hole received an initial injection of 3 gallons of water, followed by 1 gallon of FlexGel neat out of a separate dedicated SealBoss IP495 polymer injection pump. A final injection of up to 1 gallon of water through the designated water pump was then administered. During the FlexGel injection, the lance was lifted to create a vertical curtain, effectively wrapping around the found utility bay. Additional material was pumped below the elevation of the bay on either side to flood the cavity between the utility bay and the exterior of the mechanical room, creating a comprehensive waterproof barrier.

Results and Follow-Up

The initial injections were completed within a few hours, but additional cores had to be made to proceed further. A week after the installation, the area experienced heavy rains for three days. The hospital maintenance staff reported that the leak had subsided, marking a successful application of below grade waterproofing using the Curtain/Blanket Injection method with FlexGel.

Conclusion: Below Grade Waterproofing Success

This case study exemplifies the effectiveness of innovative below grade waterproofing techniques in addressing complex water intrusion issues. The use of FlexGel Hydrophilic gel in a Curtain/Blanket Injection method proved to be an efficient solution for a challenging situation, highlighting the importance of choosing the right approach and materials in below grade waterproofing projects. As the construction industry continues to evolve, solutions like these offer hope and reassurance for tackling even the most daunting waterproofing challenges.

Related Links

Leak Sealing Injection Gel

Hydrophilic Injection Foam Gel

Hydrophilic Gel

Versatile Hydrophilic Polyurethane Foam-Gel

Water activated single component hydrophilic Polyurethane grout. Reacts to a foam with 1 to 3 parts of water added and to a very flexible gel with 4 to 15 parts of water added (by volume). Drinking Water Contact meets NSF/ANSI 61 Section 5 requirements.

- Larger Projects, Extended Injection

- Electric Motor

- Piston System

- 2500 psi – 1 Comp.

STAINLESS STEEL

Dimensions

12″

36″

60″