Why Do Seawalls Fail? Causes and Repair

Why do Seawalls Fail?

Causes and Repair

Commercial and Residential Seawalls

An Overview

Why do Seawalls Fail? – Causes and Repair:

- Inadequate maintenance and inspections

- Soil erosion and overloading the soil behind the seawall

- Building too close to the wall

- Altering water flow or trapping water behind the seawall

- Using materials unsuitable for marine conditions.

- Corrosion from marine or otherwise damp environments, especially on concrete and steel rebar

- Property changes, like adding pools or buildings, that add unexpected weight

- Severe weather events that strain the seawall

Keep the Integrity of the Seawall Intact, and Avoid Erosion Inside, Under, and Behind the Seawall

Erosion is the main cause for seawall failure. Leaks within the wall, caused by cracks and failing joints, insufficient drainage of water runoff from the land-side, and other construction related problems, such as improper soil compaction, will contribute to premature and accelerating erosion, undermining the integrity and viability of the seawall.

Seawall Inspections

Frequent seawall inspections, especially after a heavy rainstorm or major storm, can help owners to early on recognize problems with their seawall, and perform seawall repairs in a timely, affordable and effective fashion. The key is to reduce or eliminate erosion in it’s early stages.

Seawall replacement is a costly construction project and most likely highly disruptive to the owner and the environment. Seawall construction could mean expensive and lengthy permitting processes, lasting weeks or months.

Maintaining Your Seawall

Every wave and tidal cycle provides a stress situation for a seawall structure, no matter how well constructed. As soil washes away, voids and gaps may form, in or under the wall. As a result, the footer may no longer supported by a solid foundation, leading to cracking of the wall and failing wall joints.

If the obvious need for seawall repair is ignored, the process of decay will continue and accelerate, potentially creating major hazards to people and the environment. Sinkholes are forming and the ground is caving in behind the wall, affecting nearby structures, including walkways and sidewalks, patios and pool deck slabs.

Seawalls, Seawall Footers and Bulkheads can be Repaired with Polyurethane Chemical Grouts and Epoxies

We provide the products and systems to stop water, fill voids, seal leaks, repair cracks, and stabilize loose soil for your seawall repair. Extend the service life of your seawall for years to come and at a fraction of the cost of replacement.

Use SealBoss Seawall Repair Systems and Products to:

- Seal Leaking Cracks and Failing Joints

- Repair Cracks Structurally to Full Strength

- Stabilize and Compact Loose Soil

- Fill Voids Behind and Under the Seawall

- Create a Waterproof Curtain Barrier Behind and Under the Seawall

Why do Seawalls Fail? – Causes and Repair:

Polyurethane Foam Grouts

Polyurethane foams are transforming seawall repair. Available in single and two-component forms, they’re effective both above and below the waterline, mending and strengthening the seawall’s foundation. These injection resins seal leaks, fill voids, and bond with soil to create a robust, impermeable barrier, enhancing seawall longevity and durability.

Epoxy Resins

Epoxy injection is vital for restoring deteriorating seawalls, concrete dock posts, and harbor structures. Best used above the waterline, it effectively seals and repairs cracks, bolstering maritime defenses’ structural integrity.

Comprehensive Seawall Restoration Solutions

SealBoss Concrete Solutions SealBoss Concrete Solutions offers comprehensive Seawall Repair Systems including eco-friendly products certified for NSF/ANSI/CAN drinking water contact.

Related Articles

- Seawall Repair Guide

- Seawall Repair with Polyurethane Foams. Plural Component vs Single Component Foam Systems

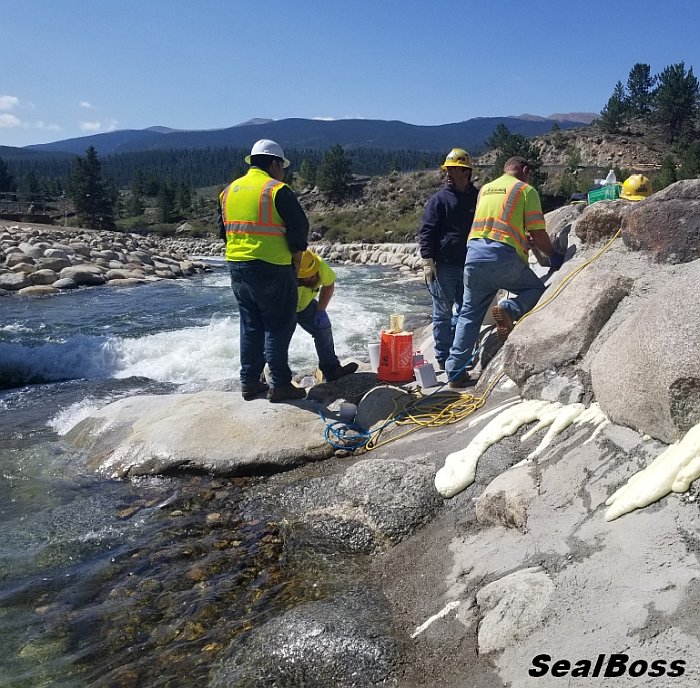

- Stone River Seawall Repair with PU Injection

Learn More

Please don’t hesitate to call us at 714-662-4445 with any questions, or request to be contacted here, we look forward to helping you find a solution. On-site support from knowledgeable and experienced technical reps is available upon request.