Bulkhead Repair

Bulkhead Repair

Bulkhead Restoration | Erosion Control | Permeation Grouting

Introduction

Welcome to our exploration of Bulkhead Repair, where we’ll delve into the essential techniques for maintaining and restoring these critical shoreline structures. Bulkheads play a crucial role in coastal and waterfront protection, acting as barriers that prevent erosion and stabilize soil along beaches, lakes, and rivers. These structures not only protect adjacent properties but also help preserve the natural shoreline and infrastructure.

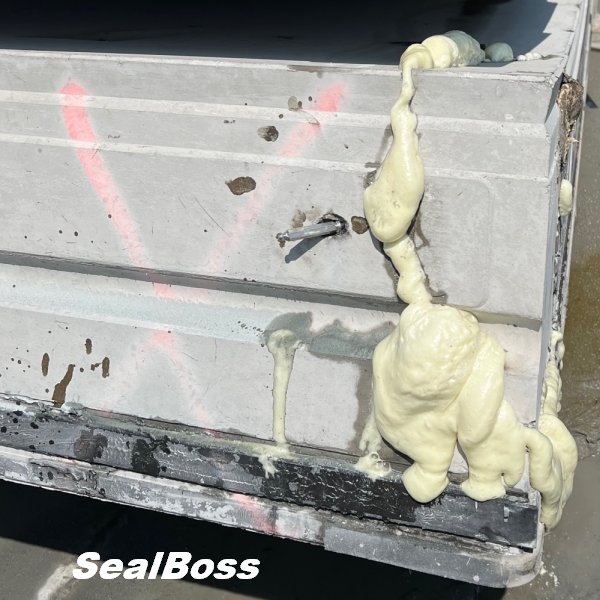

In this episode, we focus on the application of polyurethane foams—a versatile material widely used for bulkhead and seawall repairs. These foams offer several advantages: single-component foams are ideal for crack injections and permeation grouting, which anchor soils and slow erosion. Meanwhile, plural-component foams are excellent for filling voids, stabilizing concrete structures, and, under controlled conditions, even adjusting structural alignment. With their low viscosity, these foams penetrate deeply, bonding and reinforcing weak soils and damaged substrates to extend the life of bulkheads.

Whether you’re a contractor, engineer, or simply interested in learning more about infrastructure repair, this episode provides valuable insights into how modern techniques keep our coastal environments and waterfront properties protected against the forces of nature.

Unpacking Bulkhead Repair: A Deep Dive into the Use of Polyurethane Foams for Bulkhead Repair

Technical Podcast for the Infrastructure Repair Industry

Crafted specifically for marine and coastal environments, bulkheads are structures designed to strengthen soil conditions along the shores of beaches, lakes, and rivers. They not only maintain but also offer strategic protection to substrates from neighboring waters, ensuring the safety and longevity of adjacent structures. Beyond serving as mere protective barriers, bulkheads elevate the functionality of waterfront zones, ensuring a safe haven for both the buildings and the individuals who frequent the shoreline.

Join us for a captivating episode where we delve into the intricate world of bulkhead repair, focusing on the unique properties and application techniques of single and plural component polyurethane foams. Our guest, Jerald, a seasoned contractor with over three decades of experience, offers invaluable insights into the art and science of using these foams for long-lasting and efficient bulkhead restoration.

Episode Highlights:

Bulkhead Repair | Seawall Restoration | Permeation Grouting | Soil Erosion Control

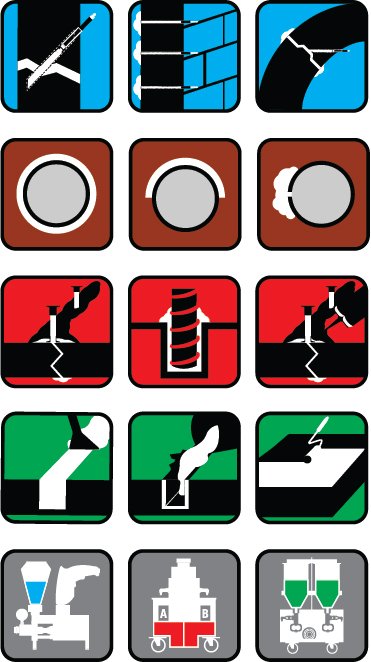

The Dual Role of Polyurethane Foams

Jerald sheds light on the distinct and synergistic functions of single and plural component foams in bulkhead repair, emphasizing their specific application techniques.

- Single-Component Foam: Ideal for water stop crack injections and substrate permeation grouting, single-component, accelerator adjusted, polyurethane foam sets the stage for comprehensive bulkhead leak sealing and soil stabilization. Master the technique of employing grout injection lances and needles to distribute the product effectively into the ground, anchoring sand and gravel — an essential measure for bulkhead stabilization and erosion prevention.

- Plural Component / Two Component Structural Void Fill and Lift Foam: Renowned for its efficiency in filling voids and stabilizing concrete structures embedded in substrate with voids and gaps, this foam can penetrate, fill, and strengthen unsupported areas effectively. In the hands of a skilled contractor, the product can be used to adjust and correct the alignment of structural elements under specific conditions. However, due to its potent expansion capabilities, it’s crucial to exercise caution. The intense outward pressure it generates could inadvertently shift structures beyond the intended position.

About Slabjack Geotechnical

Established in 2011, Slabjack Geotechnical offers a comprehensive range of concrete services, including Slabjacking (concrete raising), pressure grouting, concrete crack, and joint sealing repair. They also specialize in leak seal applications in various structures. With operations in Spokane, Tri-cities, Wenatchee, and Puget Sound, they serve Commercial, Municipal, and Industrial sectors in Washington and Idaho.

With over 30 years of successful business ownership and a knack for problem-solving, Jerald is a cornerstone of the Seattle-area Slabjack company. His expertise in Slabjacking and geotechnical projects is sought after across the USA and Canada.

A big thank you to Jerald for gracing our technical podcast and sharing his vast knowledge with our listeners!

A Conversation Between Two Industry Professionals

Our guest today

Jerald Sargent, Slabjack Geotechnical, Washington

Your host: Chris Coderre, SealBoss Corp.

Concrete Solutions Network / Sealboss ® Podcast ©

Wet Basement Repair

Wet Basement Repair

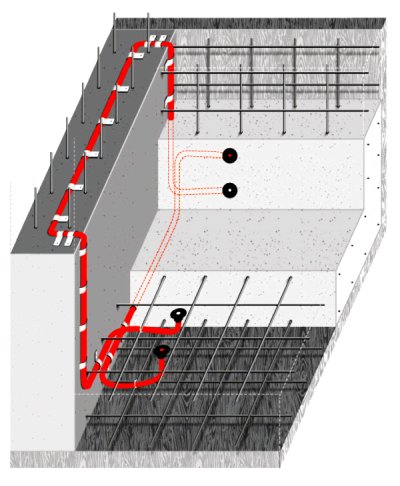

Injection System

Do You have a Wet Basement?

If you are a homeowner, one of the most frustrating problems you can encounter is a wet basement. Not only can it cause damage to your property, but it can also lead to health hazards such as mold growth and respiratory issues. Fortunately, there is a solution: the SealBoss Wet Basement Repair Injection System.

What is the SealBoss Wet Basement Repair Leak Injection System?

The SealBoss injection foam system is a waterproofing solution that involves injecting polyurethane foam into cracks and gaps in your basement walls and floors. The foam expands and hardens, creating a barrier that prevents water from entering your basement.

How does the Wet Basement Repair Injection Foam System work?

The SealBoss injection foam system works by injecting a polyurethane foam into the gaps and cracks in your basement walls and floors. The foam mixture is injected under pressure, creating a waterproof seal that prevents water from entering the structure.

The SealBoss injection foam system is also designed to be flexible, which means that it can expand and contract with your basement walls and floors as they shift over time. This prevents the foam from cracking or breaking, which could compromise its ability to keep your basement dry.

SealBoss 1510 Water Stop Foam

The SealBoss injection foam is effective, durable, and affordable. It is typically much less expensive than other waterproofing methods, such as excavation or foundation repair. It is also quick and easy to install, taking just one day or two in many cases.

SealBoss 1510 Water Stop Foam is a single component, accelerator adjusted high-performance waterstop foam that is extremely well suited for wet basement repair. This product is designed to seal gaps and cracks in concrete structures permanently, including basement walls and floors, and prevent the infiltration of water.

This product is easy to install and provides long-lasting results. Once installed, the SealBoss 1510 Water Stop Foam expands and hardens, creating a barrier that is impervious, preventing water from entering your basement.

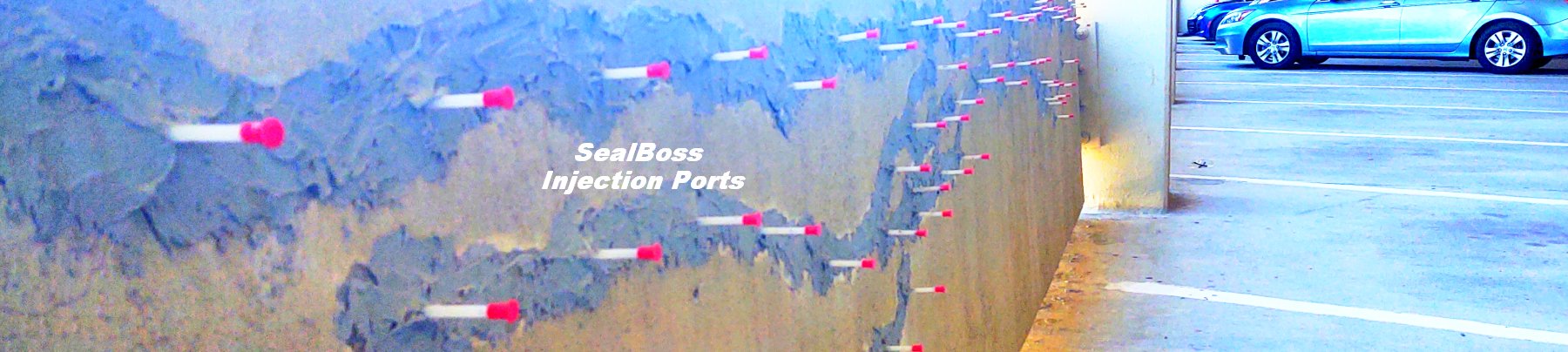

SealBoss Injection Packers

To effectively apply SealBoss 1510 Water Stop Foam, it is essential to use SealBoss Injection Packers. These specialized tools allow for the precise injection of foam into the cracks and voids in the basement walls and foundation, ensuring that the SealBoss 1510 Water Stop Foam is evenly distributed and that there are no gaps or weak spots in the waterstop barrier.

What are the benefits of using the SealBoss Injection System for Wet Basement Repair?

There are many benefits to using the SealBoss injection foam system for wet basement repair. Here are a few:

- Effective: The SealBoss injection foam system is an effective solution for preventing water from entering your basement. The foam expands and hardens to create a barrier that is impervious to water.

- Durable: The SealBoss injection foam system is designed to be durable and long-lasting. It can withstand some shifting and settling of your basement walls and floors over time, which means that it will continue to keep your basement dry for years to come.

- Affordable: The SealBoss injection foam system is an affordable solution for wet basement repair. It is typically less expensive than other waterproofing methods such as excavation or foundation repair.

- Quick: The SealBoss injection foam system can be installed quickly and easily, which means that you won’t have to spend a lot of time dealing with wet basement issues.

- Safe: The SealBoss 1510 and 1570 injection foam systems are NSF/ANSI drinking water contact certified.

How can I get the SealBoss Injection Foam System installed in my basement?

At SealBoss, we have over 30 years of experience in wet basement repair, and we are committed to providing effective solutions that work. If you’re interested in using the SealBoss injection system, be sure to contact us directly.

We can put you in touch with a professional contractor who specializes in this type of work. They will be able to assess your basement and determine whether the Injection System is the right solution for your needs. We offer complete Starter Kits for contractors and Repair Kits for smaller jobs.

Remember, a dry basement is not only aesthetically pleasing, but it can also protect your health and the structural integrity of your home. Don’t let a wet basement go untreated – please feel free to contact us at 714-662-4445, or you can request to be contacted by filling out a form on our website.

Learn more about our injection foam system and how it can help you enjoy a dry and safe basement for years to come

Starter Kit and Small Repair Kit Options

Links

- SealBoss 1510 Water Stop Foam

- SealBoss 15X Accelerator

- SealBoss 13-100AL Packers

- SealBoss R70 Pump Flush

- SealBoss Injection Pump

Related Articles

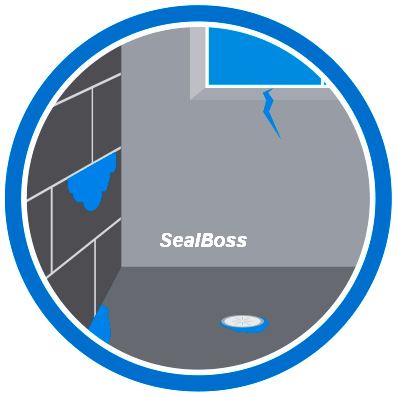

Why Do Seawalls Fail? Causes and Repair

Why do Seawalls Fail?

Causes and Repair

Commercial and Residential Seawall Repair Systems

Since 1988

An Overview

Why do Seawalls Fail? – Causes and Repair:

- Inadequate maintenance and inspections

- Soil erosion and overloading the soil behind the seawall

- Building too close to the wall

- Altering water flow or trapping water behind the seawall

- Using materials unsuitable for marine conditions.

- Corrosion from marine or otherwise damp environments, especially on concrete and steel rebar

- Property changes, like adding pools or buildings, that add unexpected weight

- Severe weather events that strain the seawall

Keep the Integrity of the Seawall Intact, and Avoid Erosion Inside, Under, and Behind the Seawall

Erosion is the main cause for seawall failure. Leaks within the wall, caused by cracks and failing joints, insufficient drainage of water runoff from the land-side, and other construction related problems, such as improper soil compaction, will contribute to premature and accelerating erosion, undermining the integrity and viability of the seawall.

Seawall Inspections

Frequent seawall inspections, especially after a heavy rainstorm or major storm, can help owners to early on recognize problems with their seawall, and perform seawall repairs in a timely, affordable and effective fashion. The key is to reduce or eliminate erosion in it’s early stages.

Seawall replacement is a costly construction project and most likely highly disruptive to the owner and the environment. Seawall construction could mean expensive and lengthy permitting processes, lasting weeks or months.

Maintaining Your Seawall

Every wave and tidal cycle provides a stress situation for a seawall structure, no matter how well constructed. As soil washes away, voids and gaps may form, in or under the wall. As a result, the footer may no longer supported by a solid foundation, leading to cracking of the wall and failing wall joints.

If the obvious need for seawall repair is ignored, the process of decay will continue and accelerate, potentially creating major hazards to people and the environment. Sinkholes are forming and the ground is caving in behind the wall, affecting nearby structures, including walkways and sidewalks, patios and pool deck slabs.

Seawalls, Seawall Footers and Bulkheads can be Repaired with Polyurethane Chemical Grouts and Epoxies

We provide the products and systems to stop water, fill voids, seal leaks, repair cracks, and stabilize loose soil for your seawall repair. Extend the service life of your seawall for years to come and at a fraction of the cost of replacement.

Use SealBoss Seawall Repair Systems and Products to:

- Seal Leaking Cracks and Failing Joints

- Repair Cracks Structurally to Full Strength

- Stabilize and Compact Loose Soil

- Fill Voids Behind and Under the Seawall

- Create a Waterproof Curtain Barrier Behind and Under the Seawall

Why do Seawalls Fail? – Causes and Repair:

Polyurethane Foam Grouts

Polyurethane foams are transforming seawall repair. Available in single and two-component forms, they’re effective both above and below the waterline, mending and strengthening the seawall’s foundation. These injection resins seal leaks, fill voids, and bond with soil to create a robust, impermeable barrier, enhancing seawall longevity and durability.

Epoxy Resins

Epoxy injection is vital for restoring deteriorating seawalls, concrete dock posts, and harbor structures. Best used above the waterline, it effectively seals and repairs cracks, bolstering maritime defenses’ structural integrity.

Comprehensive Seawall Restoration Solutions

SealBoss Concrete Solutions offers comprehensive Seawall Repair Systems including eco-friendly products certified for NSF/ANSI/CAN drinking water contact.

Related Articles

- Seawall Repair Methods Guide

- Seawall Repair with Polyurethane Foams. Plural Component vs Single Component Foam Systems

- Stone River Seawall Repair with PU Injection

Learn More

Please don’t hesitate to call us at 714-662-4445 with any questions, or request to be contacted here, we look forward to helping you find a solution. On-site support from knowledgeable and experienced technical reps is available upon request.

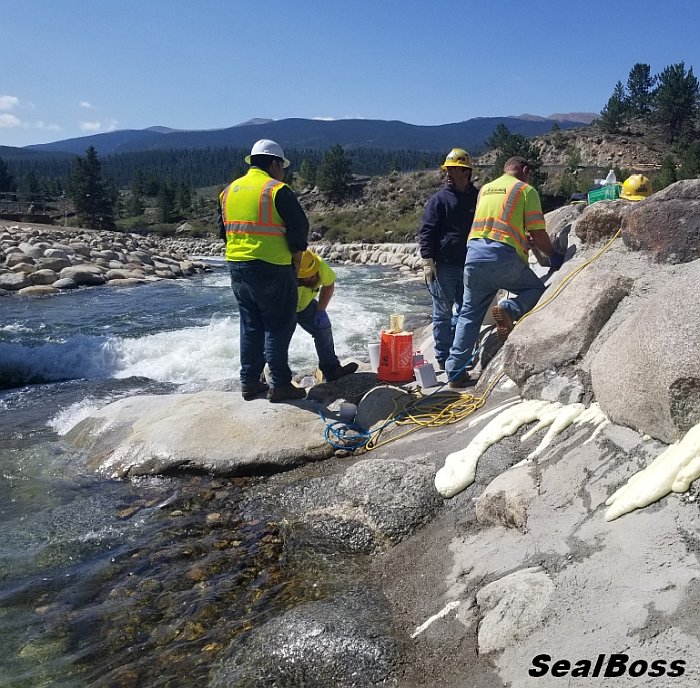

How to Seal Grout Joints in Natural Boulder | Rock | Stone River Seawall

Seawall Leak Repair with SB 1510 Injection Foam

Cold joint and crack injection of grout joints in Natural Boulder | Rock | Stone | River Seawall using the SealBoss 1510 Water Stop Foam – NSF Listed and Drinking Water System Component Approved injection System

Location: Granite Boat Chute, Arkansas River, Colorado

Objective: To Seal Leaks and Repair Cracks in Seawall Grout Cold Joints

Cold joint and crack injection of grout joints in Natural Boulder, Rock, Stone, River Seawall

SealBoss 1510 Water Stop Foam – NSF Listed and Drinking Water System Component Approved injection System

Along the beautiful and pristine Arkansas river is the Granite Boat Chute. For the first time in more than half a century, rafters and boaters can float the Arkansas River from Leadville to Cañon City without disruption.

During a repair last season on the divider seawall and re-installation of a section of the boulder wall a cementitious grout was used to bond boulders together and to bond to existing boulders and existing grout. Over time some of the cold joints between the old grout and new grout started leaking. Leaks also developed at bond failures between the natural boulders and rocks, and the cementitious grout. Hairline cracks also developed to contribute to water seepage.

SealBoss 1510 NSF hydro active foam, an environmentally friendly product with NSF drinking water contact certification, was injected into the areas of bond failure to seal the boulder seawall from water intrusion and to prevent future water induced issues with freeze / thaw cycles that contribute to further damages and eventually could lead to blowing out the seawall.

Spacing of the packers was at an interval of 12” and the catalyst was initially at a 5% by volume to allow for travel down in to the areas between the stone to ensure a proper seal throughout the conglomeration. Later the accelerator was increased to a 10% by volume to 1510 to foster a more rapid reaction and cure to fill in some of the remaining voids.

In conclusion, this project outlines innovative solutions that can be employed to address natural wear and erosion challenges.

The use of SealBoss 1510 NSF hydro active foam showcases the potential of polyurethane foam technology in ensuring the longevity and safety of such structures. By addressing the cold joints, bond failures, and hairline cracks, the SealBoss system not only rectified the immediate issues but also fortified the seawall against future damages.

SealBoss ® 1510 NSF Water Stop Foam for infiltrating water:

- Seawall Repair | Crack & Joint Leak-Seal | Soil Stabilization | Permeation Grouting

- Defective Concrete (Cracked or Honeycombed)

- Concrete Construction Joints & Cracks

- Brick Construction, Geo Formations

SealBoss ® 1510 NSF Water Stop Foam Advantages:

- Advanced NSF Formulation

- Up to 40+ Times Expansion

- SealBoss ® Product-Pump-Packer System Solution

- Unregulated For Transport

- Solvent Free MDI Technology

For hands-on or virtual training sessions, please reach out to SealBoss. Our regional technical representatives are ready to guide you through our comprehensive SealBoss system solutions and offerings. Contact us today to schedule your personalized session.

Inquire more about the outstanding SealBoss 1510 NSF Drinking Water Contact Approved Injection Foam when you call us here at SealBoss. Your representative will be happy to help you out.

Leak-Seal Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam Grout

Our #1 Selling Polyurethane Injection Foam

Water Cut-Off Injection Grout

Drinking Water Contact certified – NSF/ANSI 61 Section 5. 1510 PU Foam & Oakum Pipe Plug Kit

Flexible Injection Foam Grout For Moving Structures

SealBoss ® 1570 – The Very Flexible Injection Foam

- Moving Structures

- Crack Injection Foam

- Water Stop Foam

- Leak-Seal Chemical Grout

- NSF Drinking Water Contact Foam

SealBoss 1570 Water Stop Foam, combined with SealBoss 15x Accelerator, constitutes a hydrophobic water-activated and hydroactive grout solution. This innovative blend serves as a water cut-off and foam seal grout, grounded in MDI polyurethane technology. Notably, this resin boasts a solvent-free formulation and is entirely composed of 100% solids.

Today I like to talk our “Flexible Injection Foam Grout For Moving Structures” – SealBoss 1570

Let us discuss how SealBoss 1570 Flexible Foam is different from our flagship versatile chemical grout SealBoss 1510.

The highlight of SealBoss 1570 are the outstanding elongation and compression properties which make it a very flexible product with a bounce back performance similar to a memory foam.

SealBoss 1570 is the product of choice for environments where you expect oscillation, vibration, movement and compression.

1570 flexible water stop foam uses the standard accelerator SealBoss 15X and the liquid properties and reactive features are similar to SealBoss 1510 which make switching between products very easy and convenient.

Inquire more about 1570 Flexible Water Stop Foam when you call us here at SealBoss. Your representative will be happy to help you out.

Flexible Polyurethane Injection Foam

Flexible Foam, Water-Activated chemical grout. Water activated hydrophobic flexible polyurethane foam, expands up to 20-30 times after contact. Seals cracks, expansion joints and stops water flow. Gel-time is accelerator-adjustable. Drinking Water Contact meets NSF/ANSI 61 Section 5 requirements.

Tunnel Segment Injection Repair

Tunnel Segment Injection Repair

Chemical Grouts - Swell Tape Profiles - Swell Caulk Mastic

Mock-up Repair of a Tunnel Segment Using Polyurethane Foam Injection

Introduction

Within the intricate domain of tunnel leak sealing, polyurethane foam injection stands out for its effectiveness in tackling cracks and leaks.

This case study of a mock-up repair delves into the practical application of this method, exploring how a single tunnel segment was successfully leak seal injected with SealBoss 1510 water stop leak seal foam using specialized equipment.

Objective – Tunnel Segment Injection Repair

To seal a crack in its entirety and to its full depth, in a single tunnel segment, using polyurethane foam injection.

Methodology

Problem Identification

A prominent crack was identified in the tunnel segment, making it a prime candidate for repair. To simulate real-world scenarios, the crack was pre-injected with water to mimic a leak.

Equipment & Material Selection

Pump

SealBoss P2002 Injection Pump, known for its reliability and efficacy in such repair scenarios. The SealBoss P2002 Polyurethane Injection Pump boasts a compact design with an integrated stand. Remarkably lightweight yet powerful, it is compatible with most SealBoss® polyurethane products with viscosities between 10 and 1000 cps. This professional-grade pump offers outstanding output and pressure. Its modular design ensures low maintenance and easy cleaning.

Injection Packer

The SealBoss Evolution Long Aluminum Packer was chosen, a leading choice for deep, angled injections. or a successful injection process, mechanical injection packers and ports are crucial. Our extensive stock is curated to cater to diverse client needs, promising timely deliveries.

Foam

SealBoss 1510 Water Stop Leak Seal Foam, recognized for its water-stopping capabilities. SealBoss 1510, commonly referred to as 1510 Water Stop Foam, stands out as our premier and best-selling grout for addressing water leaks in a majority of crack injection contexts. When combined with 15x Accelerator, this hydrophobic, water-activated grout transforms into a foam seal based on MDI polyurethane. Furthermore, this resin is entirely solvent-free and composed of 100% solids.

Injection Strategy

A singular injection packer was placed at a precise angle towards the crack. This strategic positioning was critical to ensuring the foam could reach the full depth of the crack and seal it effectively.

Execution

With the equipment set and the crack prepped, the SealBoss 1510 foam was injected using the SealBoss P2002 pump through the SealBoss Evolution packer. The foam’s expansive properties, coupled with the angled placement of the injection packer, ensured the material filled the entire crack from depth to surface.

Outcome – Tunnel Segment Injection Repair

Upon completion of the injection process, a thorough inspection was conducted to verify the effectiveness of the repair. The results were clear – the crack had been sealed entirely, with complete, uninterrupted foam penetration along the perimeter.

Key Learnings

Strategic Packer Placement

The success of this repair underscored the importance of correctly positioning the injection packer. An angled approach ensured the foam covered the crack’s entire depth.

Reliable Equipment

The SealBoss P2002 injection pump and SealBoss Evolution packer proved indispensable, delivering the foam efficiently to the target site.

Efficacy of SealBoss 1510

This particular foam showcased its prowess in stopping water ingress, highlighting its potential as a top-tier solution for tunnel repairs.

Conclusion

This case study stands as a testament to the efficacy of polyurethane foam injections in tunnel repair scenarios. When executed with precision and the right equipment, even a single injection point can address extensive cracks, ensuring the longevity and safety of critical infrastructure like tunnels.

Tunnel Segment Injection Repair and other SealBoss Tunnel Sealing Solutions

- Chemical Grouts

- Epoxy System

- Joint Seal Systems Overview

- Swell Tape – Swelling Rubber Profile Strips

- Swell Caulk – Hydrophilic Swelling Mastic

Tunnel Injection Repair Equipment

Leak-Seal Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam Grout

Our #1 Selling Polyurethane Injection Foam

Water Cut-Off Injection Grout

Unregulated for transport. Drinking Water Contact meets NSF/ANSI 61 Section 5 requirements. 1510 PU Foam & Oakum Pipe Plug Kit

Basement Crack Injection Kit

Basement Crack Injection Kit – The Ultimate Solution for Leak Sealing and Repair

Tracing the Root Cause

The culprits behind basement cracks often lie in the settlement of backfill or inadequate soil conditions. The resulting stress cracks can pave the way for unwelcome moisture intrusion, leading to further damages and the development of mold and unsightly damage over time.

A Comprehensive Crack Repair System

Enter the SealBoss Basement Crack Injection Kit, your ultimate weapon against leaks. This kit simplifies the repair process by delivering an effective, user-friendly solution to stop water in its tracks. The cured seal is airtight, watertight, and hydrophobic, deterring water incursion with utmost efficiency.

Our easy to use kit comprises a SealBoss P2002 high-pressure injection pump, SealBoss 1510 Water Stop Foam hydrophobic resin coupled with a 15x catalyst, and SealBoss Mechanical Injection Packers. When used in unison, these tools empower you to counteract hydrostatic pressure and fill the crack with a specialized water activated polyurethane foam that reacts with the existing moisture.

For complex structural repairs, consider employing the SealBoss Epoxy Injection System and Epoxy Repair Kits. For an in-depth comparison of the two systems, we invite you to explore our article on Epoxy versus Polyurethane.

Crack injections can conveniently be performed from within the structure (aka negative side repair), saving you both time and labor.

Leak Sealing Crack Repair Procedure

We put our Crack Injection Kit to work in a residential basement structure that had three prominent cracks showing signs of moisture intrusion. Signs of a previous unsuccessful repair attempt were also evident.

Post a thorough cleaning and strategic planning, we embarked on the repair process using our 1, 2, 3, 45 Degree Injection Guidelines, initiating with hole placement. The positive movement of water from drill hole to crack and inter-hole travel confirmed the readiness for the crack to be sealed.

The cracks, being approximately 3/8” wide, demanded a slowed injection to prevent wastage and overfill. As the catalyzed 1510 hydrophobic resin flowed from the crack, we employed a spray bottle to expedite the hydro-active reaction of the SealBoss 1510, allowing the foam to seal the crack surface as it cured.

One significant vertical crack had penetrated the foundation and was visible above ground. This crack was treated with foam from the floor up to 12” below the sill plate. The exterior was sealed to guide the expansion and avert exterior leakage. All cracks were sealed successfully, with surplus foam removed to prepare the structure for subsequent treatments, including aesthetic improvements.

Please note, we highly recommend consulting a specialist to investigate and correct any underlying and ongoing causes of structural damages, crack formation, and settling — including, but not limited to, backfill settlement and poor soil density.

SealBoss Water Stop & Leak Sealing Injection Pro Kit

Injection Resin: SealBoss 1510 w/ 15x Accelerator

Injection Packers: 1/2” 13-100 Evolution Aluminum Packers

High Pressure Pump: P2002 Single Component Injection Pump

Cleaning: R70 Pump Flush

Other Tools Used

Cleaning Materials: Xylene, rags, bucket

Additional Tools: 18” x 1/2″ drill bit — 3/8” Crescent Wrench — Dead Blow Hammer

Hammer Drill — Access 110v Power —

Vacuum

Enjoy Peace of Mind with the SealBoss Concrete Solutions

With our Basement Crack Injection Kit, not only do you have an effective repair solution at your fingertips, but also a path to restore your basement’s integrity and aesthetics. Gone are the days of continually battling the damaging effects of moisture intrusion. Instead, look forward to the assurance of a drier and healthier environment.

Remember that it’s crucial to address any root causes contributing to your basement’s damage. Regular maintenance, appropriate landscaping, and proper drainage can play a significant role in preventing cracks and leaks in the future. If you’re unsure about these aspects, we recommend involving a professional to help you take the right steps.

Your Partner in Crack Repair

We’re more than just providers of crack repair solutions. At SealBoss, we’re committed to being your partner in navigating basement repairs. From understanding the nuances of polyurethane and epoxy, making the right product choice, to walking you through the repair process, we’re with you every step of the way.

Need technical support, additional information, or advice on our products? Don’t hesitate to reach out to us. We’re here to ensure you have everything you need to succeed in your repair projects and maintain the health and longevity of your structure. Trust in us, because with SealBoss, successful basement restoration begins.

Comprehensive Solutions for All Sizes

We understand that not all repair jobs require extensive tools and materials. For those smaller tasks, check out our tailored Small Job Kits. They’re specially designed to handle minor repairs, ensuring you get the same high-quality results without needing to invest in larger quantities or more extensive equipment.

Popular Water Stop & Leak Sealing Injection Links

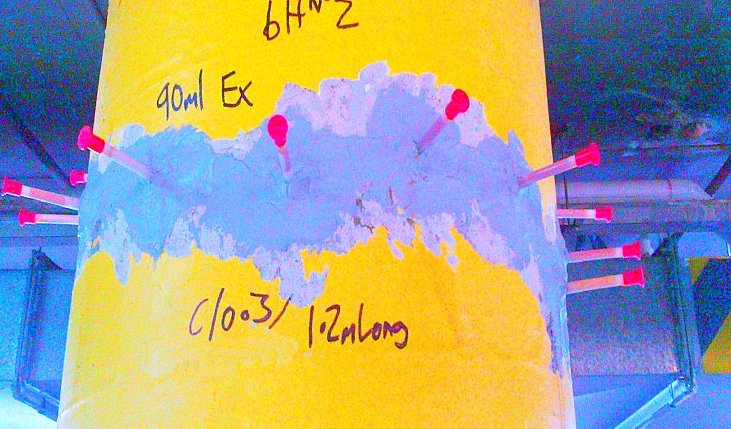

Vehicular Barrier Wall – Bumper Wall Repair

Vehicular Barrier Wall / Bumper Wall Repair

Epoxy Dispensing Systems

An Overview to Vehicular Barrier – Bumper Wall Crack Repair in Parking Garages Using the SealBoss P3003 Epoxy Injection Pump and SealBoss Surface Mounted Tri-Base Epoxy Injection Port System

Maintaining the integrity and safety of parking structures is paramount, specifically the vehicular barriers or bumper walls. These walls play a significant role in preventing accidents, thereby ensuring the protection of property and human lives.

Over time, due to various factors such as stress, wear and tear, or movement of reinforcing lateral cables causing additional forces, these barriers often develop structural and shrinkage cracks. This is where the technology of epoxy injection comes to the rescue.

The Damage: Cracked Vehicular Barriers

Cracks can be a source of structural weakness in parking garage bumper walls. They may compromise the strength and stability of the barrier, leading to potential safety hazards. Additionally, moisture seeping through these cracks can cause the steel reinforcement to corrode and the concrete to spall, igniting a vicious cycle of accelerating deterioration.

The Answer: Epoxy Injection

Epoxy injection presents itself as a proven, cost-effective method to repair cracks in structures. The technique involves the injection of a low-viscosity epoxy into the cracks. The injected epoxy fills the void and, once cured, can restore the structural integrity and strength of the concrete structure, warding off further damage.

The Tools: Epoxy Dispensing System

Proven reliability and cost-effectiveness, the SealBoss P3003 Epoxy Injection Pump and SealBoss Surface Mount Tri-Base Ports exemplify a professional solution for epoxy pressure dispensing.

Scope: Inject Structural Cracks on Exterior Vehicular Barrier Wall

Professional Epoxy Dispensing System:

SealBoss P3003 Epoxy Injection Pump & SealBoss Surface Mounted Tri-Base Ports

A successful epoxy injection process relies heavily on the right equipment. The SealBoss P3003 Epoxy Injection Pump and SealBoss Surface Mounted Tri-Base Ports are precisely designed to manage such repairs. Specifically, the P3003 pump is custom-designed with a 2:1 ratio feature in mind, or, if needed, a 1:1 ratio conversion, vital for most structural epoxies, providing optimal curing and strength characteristics.

Procedure: Repairing Cracks with Epoxy Injection

The epoxy injection process kicks off by preparing the crack for repair. Any loose concrete or debris within the crack is removed, the paint is grinded off, and the surface is cleaned thoroughly. For fine shrinkage cracks, the contractor chases the cracks out to allow for proper material travel during injection.

Connectors: SealBoss Tri-Base Ports

The SealBoss Surface Mounted Tri-Base Ports are strategically installed along the crack. Acting as a connector between the injection machine or dispenser, they are placed directly over the crack, and a non-sag, fast setting epoxy paste is built up around the port to ensure a proper seal that can hold pressure.

Epoxy Injection Port – Industry Standard Bestseller

Durable plastic design surface mounted port. Tri-Base design with perforation holes for best possible adhesion. .

Dispenser: SealBoss P3003 Epoxy Pump

Having completed the preparation phase, the SealBoss P3003 Epoxy Injection Pump is effectively engaged as the device for dispensing the epoxy. This allows for the precise injection of the epoxy resin into the existing cracks through the strategically placed ports. The process starts at the lowest port on a vertical crack or the first port on a horizontal crack. Epoxy is injected until it begins to appear at the next port, signifying that the section of the crack between the ports has been filled. The injection process then proceeds to the next port, repeating the process until the entire crack has been repaired.

Once the epoxy has cured, the ports and the surface seal are removed. The result is a structurally sound bumper wall, restored to its original strength and durability.

- Versatile,

- Pumps Epoxy & PU Resin

- Electric Drill Operated

- Dual Piston System

- 5000 psi

- 2 Comp.

- Ratio: 2:1 standard, 1:1 custom

Conclusion

The fusion of the SealBoss P3003 Injection Pump with the SealBoss Surface Mounted Tri-Base Port connection system, complemented by superior-quality epoxy polymer resin, forms an efficient solution for concrete injection tasks.

Designed to address a wide variety of concrete repairs, its capabilities extend well beyond fixing vehicular barriers in parking garages, providing a robust system for an extensive range of concrete structures.

It is always advisable to engage professionals experienced with epoxy injection techniques to ensure the most effective and optimal results for these critical repairs.

Additional SealBoss Surface Ports and Epoxy Pumps

Epoxy Injection Corner Port

Durable plastic design corner surface port suitable for epoxy injections. Corner base design with perforation holes for best possible adhesion.

Epoxy Injection Drill Hole Mount Port

Durable plastic port designed to fit 1/2″ drill hole for higher injection pressures than regular surface ports.

- Top of the Line – Professional Use

- Pumps Epoxy & PU resin

- Pneumatic

- 850 psi

- 2 Comp.

- Ratio: 2:1 Standard, 1:1 custom

- Top of the Line – Professional Use

- Pumps Epoxy & PU resin

- Pneumatic

- 1000 psi

- 2 Comp.

- Ratio: 2:1 Standard, 1:1 custom

SealBoss Epoxy Injection System

Related Articles

Sealing Leaking Conduits

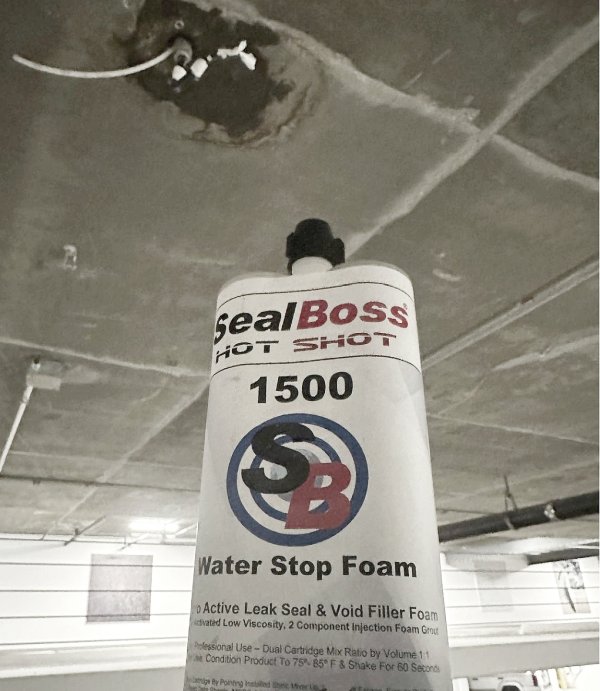

Sealing Leaking Conduits

An Effective Solution:

Using SealBoss 1500 Hot Shot Cartridges

Tackling leaking conduits can be quite daunting without the appropriate tools and products. Thankfully, a reliable and effective solution is available – SealBoss 1500 Hot Shot Cartridges. This cartridge provides a swift cure, dispensing a hydrophobic polyurethane foam that stops water and seals leaks efficiently.

Big Shots – Understanding SealBoss 1500 Hot Shot Cartridges

This hydrophobic, water-activated grout is a leak-seal foam based on a phthalate-free, MDI polyurethane. Being a 100% solvent-free, 100% solids two-component formulation mixed at a 1:1 ratio by volume, it’s an eco-friendly solution designed to seal leaks effectively.

When it comes into contact with water, SealBoss 1500 Hot Shot Polymer reacts to form a semi-flexible foam, expanding its volume by 30 to 40 times. The cured material retains a constant volume, and because water isn’t a component of the foam structure, the cured material is virtually unaffected by water or dryness. As a result, the material essentially doesn’t shrink or swell.

SealBoss 1500 Hot Shot Cartridges are expertly designed stop water seepage and to fill both small and large voids typically present in conduits and around pipe penetrations.

Excelling as both a filler and sealer, 1500 Hot Shots are adaptable to a range of environments, including gravel layers, rock fissures, and joints, as well as cracks in concrete structures. Its ability to abruptly halt high-pressure and high-speed water flows makes it an exceptionally versatile solution, even in the most challenging leakage scenarios.

The Oakum Soakum Technique

You can also use SealBoss 1500 Hot Shot Cartridges with SealBoss 1500 Seal Oakum by employing the ‘Oakum Soakum Technique.’ This method further enhances the seal’s effectiveness, especially in challenging environments.

Sealing Leaking Conduits with SealBoss Hot Shots

Ensure that the cartridge is thoroughly shaken, affix the Static Mixer, and then insert it into the application gun. Now, you’re all set to dispense the product and achieve a permanent seal.

SealBoss 1500 Hot Shot Cartridges are part of the SealBoss Cartridge System. The mix ratio by volume is 1:1, ensuring ease of use and optimal effectiveness. It reacts with the moisture in the substrate, eliminating the need for added amounts of water for the reaction to occur.

“Injections of leaking conduits with @sealbosscorp 1500. Simple fix”

– Surfside Restoration on the efficacy of SealBoss Hot Shot Cartridges

In Conclusion

SealBoss 1500 Hot Shot Cartridges offer an effective, efficient, and eco-friendly solution to sealing leaking conduits. By choosing this product, you’re opting for a reliable, high-quality product designed to handle leaks of varying degrees, ensuring the longevity and proper functioning of your systems. Always consult with a professional if you are unsure about any steps in the process to guarantee the best results.

Related Product – See What this CAN can DO: