Super Low Viscosity Epoxy Crack Healer & Sealer | SealBoss 4050 SLV

Super Low Viscosity Epoxy Crack Healer & Sealer

Epoxy Resin 4050 SLV

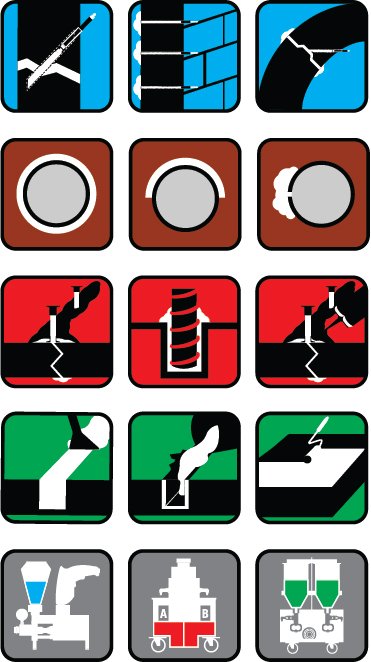

SealBoss ® 4050 SLV Epoxy Grout Applications

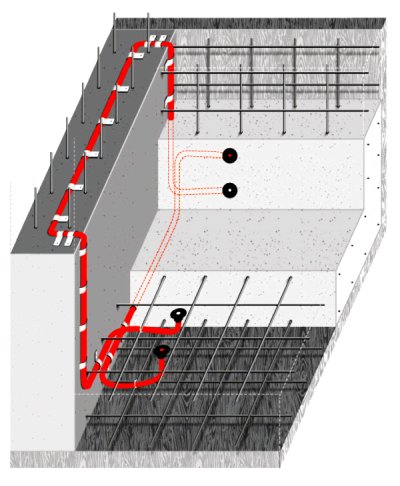

- Structural Epoxy Crack Injection

- Gravity feed or pressure injection of fine cracks in structural concrete, masonry, rock, wood.

- Seal interior slabs and exterior above grade slabs

SealBoss 4050 SLV Epoxy Grout Resin – Super Low Viscosity Crack Healer & Sealer

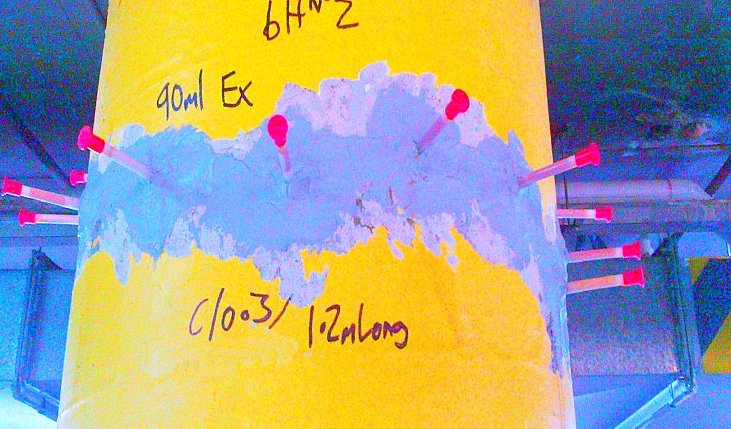

SB 4050 SLV is a 2-component, 100 % solids, super low-viscosity, high-strength, low surface tension, moisture-tolerant, epoxy resin crack healer and deep penetrating sealer designed for high strength repairs, epoxy injection and epoxy crack injection in concrete substrates such as floors, ceilings, walls, foundations and more. SealBoss 4050 SLV is formulated for grouting both dry and damp cracks. 4050 SLV meets ASTM C-881 and AASHTO M-235 specifications.

Key Features:

- High Strength and Durability: Engineered for high-strength repairs, it is ideal for restoring the integrity of concrete structures

- Exceptional Penetration: Its low viscosity allows it to seep deeply into fine cracks, ensuring comprehensive healing and sealing

- Versatile Application: Suitable for use in a variety of concrete substrates including floors, ceilings, walls, foundations, and more

- Moisture Tolerance: Effectively grouts both dry and damp cracks, offering flexibility in diverse environmental conditions

- Low Surface Tension: Enhances the product’s ability to penetrate and bond to the concrete, providing long-lasting repairs

- Compliance with Standards: Meets the rigorous ASTM C-881 and AASHTO M-235 specifications, ensuring quality and reliability

SealBoss ® 4050 SLV Super Low Viscosity Epoxy Resin Advantages

- Easy mix ratio A:B = 2:1 by volume

- Advanced strong bonding structural resin

- Super Low viscosity – Low surface tension

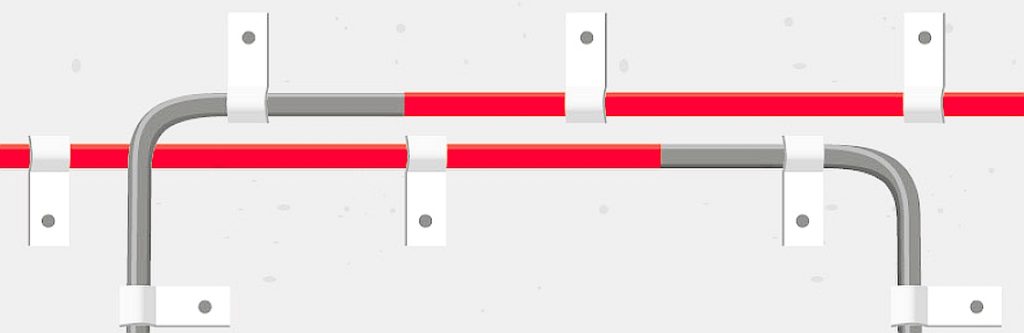

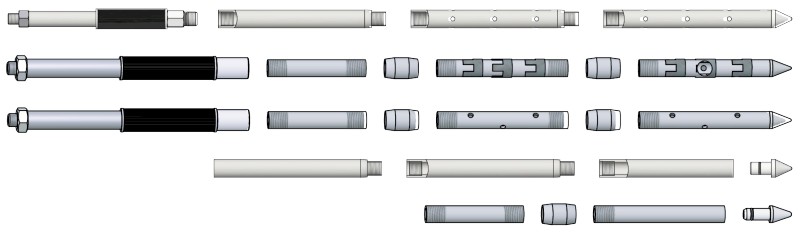

- Stronger than concrete

SealBoss 4050 SLV is our super low viscosiy epoxy crack healer & sealer epoxy resin suitable for hairline crack epoxy injection jobs. We offer a comprehensive selection of epoxy injection equipment and accessories including professional epoxy injection pumps, injection ports, hoses and applicators.

For smaller jobs we provide epoxy resins and other professional grade products in dual cartridges as a convenient alternative to bulk products.

Inquire more about our systems when you call us here at SealBoss. Your representative will be happy to help you out.

For smaller jobs we provide epoxy resins and other professional grade products in dual cartridges as a convenient alternative to bulk products.

Inquire more about our systems when you call us here at SealBoss. Your representative will be happy to help you out.

Chris Coderre

Regional Sales Manager

Contact Your SealBoss ® Technician

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.