Retaining Wall Repair

Retaining Wall Repair

Injection Methods Compared

Understanding Retaining Wall Repair:

Polyurethane vs. Epoxy Injection Methods

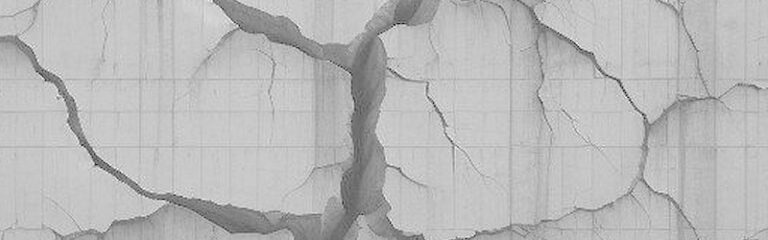

Retaining walls play a pivotal role in infrastructure and landscape, offering both functional support and aesthetic appeal. These structures, while robust, are susceptible to environmental factors and age related weakening that can lead to cracks, spalls, water leakage, or other forms of structural damage.

Addressing these issues promptly and effectively is crucial to ensure the longevity and safety of the wall. In the realm of deep penetrating, effective sealing and high strength structural retaining wall repairs, two methods have emerged as frontrunners: Polyurethane and Epoxy injection.

This overview explores the intricacies of both methods, comparing their advantages, applications, and effectiveness to guide you in making an informed decision for your retaining wall repair needs.

Retaining Wall Repair

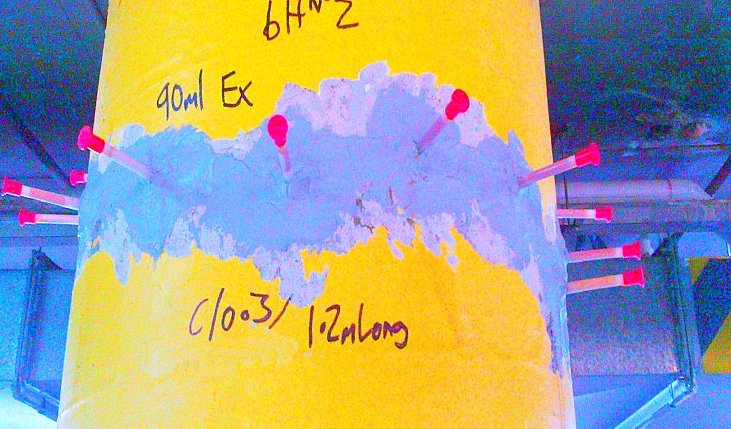

with Leak Sealing Polyurethane Water Stop Foam Injection

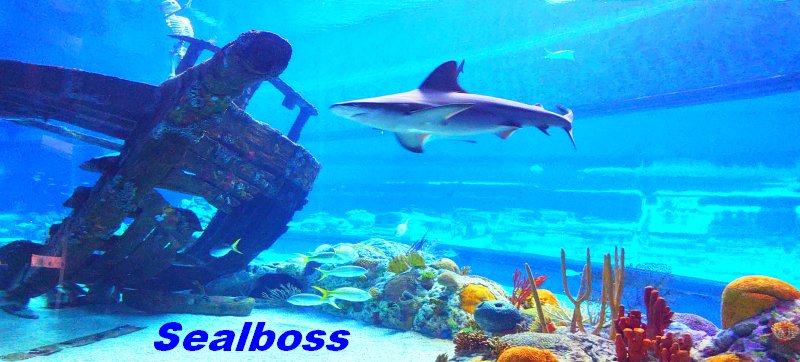

Retaining walls serve as crucial components in construction projects, especially when dealing with slopes or elevated terrains. Their primary function is to combat soil erosion and bolster the stability of structures by resisting the pressures of soil and water. Yet, like all structures, retaining walls are prone to wear and tear, often manifesting as water leakage and subsequent erosion.

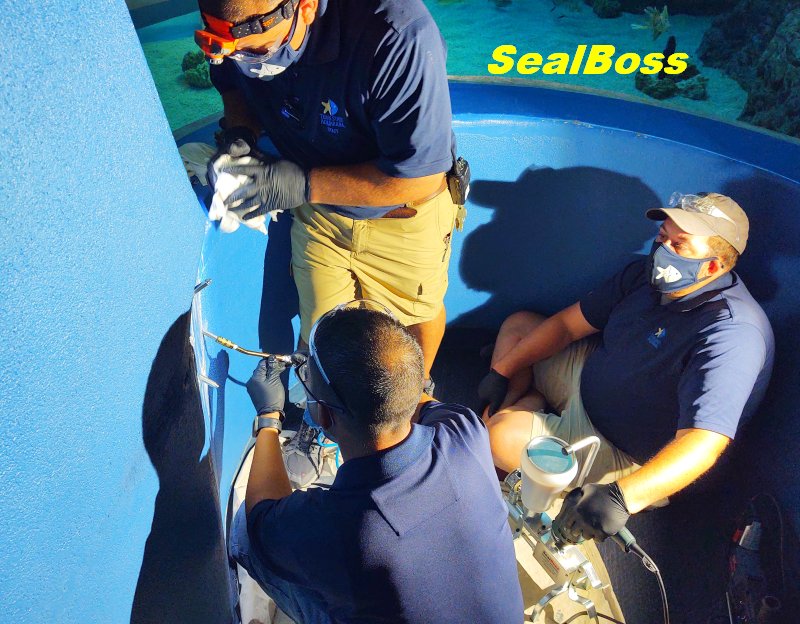

Enter polyurethane injection, a game-changer in the realm of retaining wall repairs. This method stands out not only for its efficacy but also for its cost-efficiency. Unlike traditional repair methods that might involve extensive excavation, the use of heavy machinery, or prolonged construction periods, polyurethane injection offers a swift and minimal-disruption solution. The essence of this method lies in the foam grout injected, which forms a resilient waterproof barrier, crucial for walls constantly exposed to moisture and hydrostatic pressure.

At its core, polyurethane injection foam is engineered to expand upon water contact. Typically, this foam is introduced into cracks or voids within a structure. Upon encountering water, a chemical reaction is triggered, causing the foam to swell and occupy the space. This unique expanding property is invaluable for tasks like leak sealing, ensuring that the foam aptly fills gaps and halts further water penetration.

The combination of low viscosity, fast expansion and curing, flexibility, good chemical resistance and adhesion, make polyurethane injection foam grout an effective choice for leak seal and water stop injection applications.

Here are some advantages of using PUR foam for stopping water migration through retaining walls:

- Cost-effective — Polyurethane injection is a cost-effective solution for repairing a leaking retaining wall. It requires less labor, time, and materials compared to traditional methods of repair, such as excavation and replacement

- Water Stop Leak Sealing and Waterproofing — The injected polyurethane resin expands on contact with moisture and creates a waterproof compression seal that prevents further water infiltration into the retaining wall

- Minimal-Invasive — Polyurethane injection requires minimal disruption to the surrounding area, making it a convenient solution for homeowners and business owners. It does not require excavation, heavy machinery, or lengthy construction timelines

- Quick — Polyurethane injection can be completed quickly compared to traditional methods, minimizing the time that the retaining wall is out of commission and minimizing disruptions to daily activities

- Durable — The injected polyurethane resin creates a strong and flexible bond with the concrete surface, making it a durable and long-lasting solution for sealing a leaking retaining wall

Summary

Polyurethane injection is a cost-effective, waterproof, minimal-invasive, quick, durable, versatile, and eco-friendly solution for sealing a leaking retaining wall. If you are facing a leaking retaining wall, consider using this method for an efficient and effective repair solution.

Retaining Wall Repair

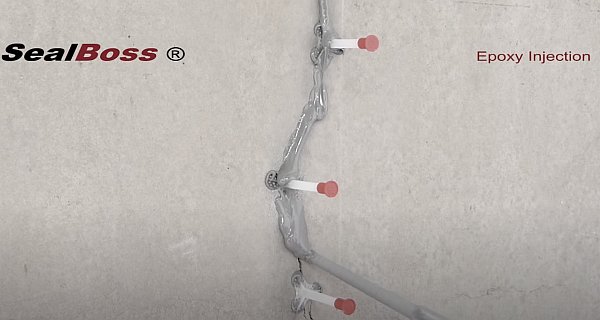

with Epoxy Resin Injection For Structural Strength

Retaining walls play an indispensable role in both landscape and infrastructure, acting as bulwarks against soil erosion and providing essential structural support. Yet, like all structures, they are vulnerable to the elements, facing challenges like natural degradation, water-induced damage, and the relentless pressure from the soil. Over time, these factors can result in cracks, voids, and other structural concerns. Left unaddressed, these issues can jeopardize the wall’s stability and safety. This is where epoxy resin injection comes into play, offering a robust solution to restore and reinforce a retaining wall’s strength.

Here is a closer look at the benefits of using epoxy resin injection for retaining wall reinforcement:

- Structural Strength Repair — Retaining walls can lose their structural strength due to natural wear and tear, crack development, water damage, and soil pressure. Epoxy resin injection can fill and reinforce the damaged areas, restoring the retaining wall’s strength and stability. Epoxy resin, known for its high compressive and tensile strength, can fortify damaged areas, resisting both compressive and tensile forces. Its ability to prevent crack propagation and bear significant pressures and loads makes it a prime choice for restoring walls facing soil and water pressures

- Durability — Epoxy resin injection is a durable solution for retaining wall repair. Epoxy resin is resistant to water, many chemicals, and typical ambient heat. It also resists wear and tear, making it a long-lasting solution that can withstand the test of time

- Cost-effectiveness — Opting for epoxy resin injection can be a financially savvy decision. When compared to the steep costs associated with wall replacement—which often involves excavation, demolition, and rebuilding—epoxy injection emerges as a cost-effective alternative

- Minimal-Invasive — Epoxy resin injection is a minimal-invasive solution for repairing retaining walls. It does not require excavation, heavy machinery, or lengthy construction timelines, minimizing the disturbance to the surrounding area

- Quick — Time is of the essence in repair projects. Epoxy injection offers a faster turnaround than many traditional methods, ensuring the retaining wall is swiftly restored to functionality, with minimal disruption to daily routines

Summary

Epoxy resin injection is a reliable and efficient solution for structural retaining wall repair, offering a range of advantages such as durability, high compressive and tensile strength, cost-effectiveness, and minimal-invasiveness.

For any structural repair project, it is highly recommended to seek guidance from a professional engineer to assess the suitability of epoxy injection. Additionally, it is important to hire a skilled and experienced epoxy injection contractor who can perform the repair in accordance with the specifications. This ensures that the repair is conducted safely and effectively, and that the structure is restored to its optimal condition. It is crucial to prioritize safety and quality when it comes to structural repairs — expert advice and hiring competent professionals can help to achieve these goals.

Conclusion

Retaining Wall Repair – Polyurethane or Epoxy Injection

- Polyurethane foam injection can be applied effectively in a wet environment where active water leaks are present. When the foam is injected, it expands and creates a water-resistant barrier that forms a permanent, flexible or semi-flexible seal upon contact with water. In most cases, there is no need to surface seal cracks before injecting the foam. Injection packers can be installed in wet environments and injection is not impacted by active water flow. While water-bearing cracks can lead to structure deterioration and erosion over time, they often do not compromise the structural integrity of the building if recognized early and sealed promptly

- While structural epoxy injection can effectively restore a retaining wall’s strength and integrity, it is most effective in a dry environment. Epoxy is not well-suited to stop active water leaks. The injection area requires more preparation work, and it is recommended to surface seal cracks before injecting the epoxy. Surface ports do not adhere well in very wet environments. This repair method is more time-consuming and labor-intensive compared to polyurethane foam injection, and it can be more expensive

In summary, both polyurethane foam injection and structural epoxy injection are effective repair methods for retaining walls. Polyurethane foam injection is a highly effective method for preventing water infiltration, stopping active water flow, and efficiently and permanently sealing cracks. Structural epoxy injection is most suitable for application in environments that are not actively leaking and require additional support for significant structural damage in the wall.

Ultimately, the choice of injection repair method will depend on the specific project requirements.

It is always recommended to consult with a qualified professional to determine the best approach for your retaining wall repair needs.