Hairline Crack Injection

Hairline Crack Injection

Super Fine Crack Injection

What are Hairline Cracks and how do they develop?

Fine cracks in concrete, thinner than a credit card thickness, are considered hairline cracks. here are a number of reasons concrete structures could form hairline cracks.

Common causes of hairline cracks in concrete structures and foundations

Shrinkage

Concrete shrinks in volume as it dries. During this process of contraction, hairline cracks may develop.

Thermal Movement

Concrete expands and contracts during temperature changes. This process can cause hairline cracks to form in the structure.

Settlement

Foundation settlement can cause stress in a structure and lead to cracking. Voids varying in size from hairline cracks to more severe fractures and fissures can be observed.

Hairline Crack Injection Job Walk Comments

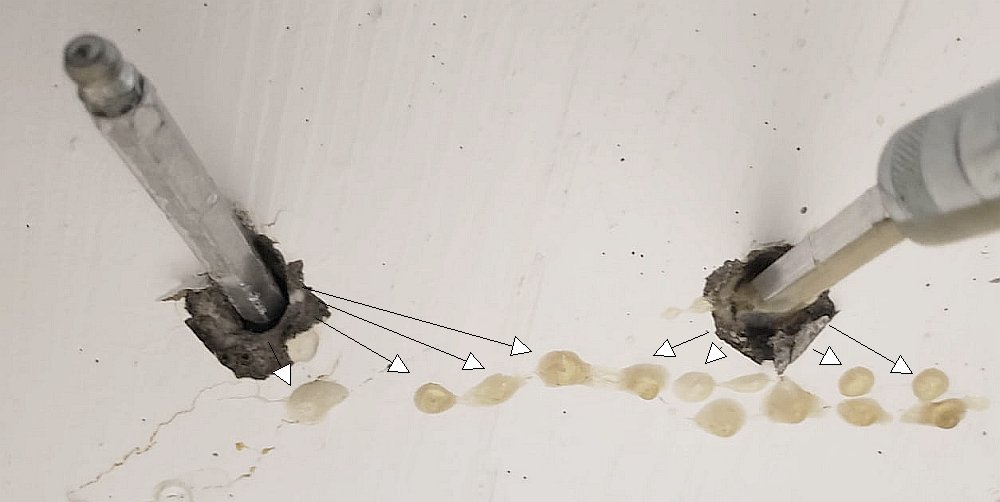

– In the image presented, we highlight a detail we have previously discussed with the injection team during technical training. The almost imperceptible hairline crack beautifully demonstrates the resin’s travel, moving from the drilled hole pointy of injection within the crack and emerging on the wall’s surface.

For effectively treating ultra-thin hairline cracks, it is advisable to utilize a low-viscosity chemical injection grout. This ensures optimal material penetration within the structure. Additionally, injection packers are typically positioned in close proximity to one another and nearer to the crack. This arrangement is due to the anticipated higher injection pressures and the increased challenges associated with material dispersion.

Hairline Crack Injection Products Used

The contractor performed the hairline crack injection with the SealBoss Injection System.

Products used:

- Hydro-active low viscosity polyurethane foam injection grout SealBoss ® 1510 Water Stop Foam

- SealBoss Injection Packer Evolution 13-100 AL

We also recommend for hairline crack injection:

- SealBoss 1570 LV Low Viscosity Polyurethane Water Stop Injection Foam

- SealBoss 1403 SLV Super Low Viscosity Polyurethane Resin for injection into very fine cracks

- SealBoss 2400 SealGel SLV Super Low Viscosity Acrylate Gel / Acrylic Gel

Learn More

Please don’t hesitate to call us at 714-662-4445 with any questions, or request to be contacted here, we look forward to helping you find a solution. On-site support from knowledgeable and experienced technical reps is available upon request. Check out our Crack Injection Kits.

Got Training?

Got Training?

Chris Coderre, SealBoss Sales Manager West, enjoys sharing his experience with everyone in the industry

Cascade AquaTech hosts another successful SealBoss ® Classroom day. We like to thank Ben Servais and the Alberta team for organizing and hosting this event which brings manufacturer, distributor and customer together for a great learning experience. We appreciate everyone who made the time to show up and meet with Chris in person.

We bring the SealBoss ® Classroom to you

PolyLifter Pro 2 | SealBoss Plural Component Polyjacking & Slab Lifting Pump

PolyLifter Pro 2

SealBoss Plural Component Polyjacking & Slab Lifting Pump

Polyjacking Made Easy with Heated Polyurethane Pump System

- Max output flow up to 5 gal / min

- Mixing ratio 1:1

- Heating power 7.5KW

- Heating temperature max. 175 F, 80 C

- Max heating hose length 250 ft, 75m

- Working pressure max. 1600psi , 11Mp

- Air Intake max. 120 psi, 0.8Mpa, max 0.9m³/min

SealBoss ® PolyLifter Pro Pump

SealBoss offers high quality slab lifting equipment at very affordable prices with focus on smaller to mid size jobs.

We provide concrete contractors and specialty contractors with a system solution of quality injection foams and pumps to perform void fill and polyjacking applications at competitive prices.

For detailed information and pump demonstrations please contact your technical sales representative.

Ceiling Crack Injection Shopping Mall

Ceiling Crack Injection

Shopping Mall

SealBoss ® 1510 Water Stop Foam Ceiling Crack Leak Repair

Job Walk Shopping Mall Los Angeles

Before and after pictures. Ceiling leak repair. Hydroactive polyurethane foam grout injection with SealBoss ® 1510 Water Stop Foam and SealBoss ® Packer Evolution 13-100 AL.

SealBoss 1510 Water Migration Stop In Conduit

Water Migration Stop in Conduit

Injecting SealBoss 1510 into Conduit to Stop Water Migration

Contact Your SealBoss ® Technician

Basement Waterproofing Products

Basement Waterproofing Products

Seal Basement Leaks & Fix Cracks

Basement Cracks, Foundation Leaks, Damp & Wet Basement Walls

Many Homeowners with Poured-in-Place Concrete Foundations will find Cracks in their Basement Walls on Closer Inspection.

Basement cracks develop by drying shrinkage, thermal movement, and other causes. If minor, they will cause no immediate problems. But over time, minor cracks often grow larger and cause major headaches, including reduced structural integrity or water leakage.

Homeowners with a leaky basement can have these cracks fixed permanently. Often without costly, disruptive excavation by using pressure injection with epoxy resin or water activated, hydro-active polyurethane foam repair materials.

We now offer Do It Yourself Basement Waterproofing Products as Kits for leak repair and structural basement crack repair.

By sealing smaller cracks with a DIY Crack Repair Kit, the homeowner may save a significant amount of money. Even if a crack is not leaking yet, eventually water might find a way through it. We supply commercial grade epoxy resins and leak seal water activated polyurethane foams for all types of foundation crack and wall crack repairs.

Crack injection has been performed and improved on for several decades. In many cases, crack injection will fix the problem. The injection procedure will permit to fill the crack in full, from front to back, with epoxy resin or polyurethane grout. Injection has shown to be effective for filling cracks from 0.001 to over 2 inches wide. It can also be used to fill cracks in concrete floors and ceilings.

In most cases homeowners can have these cracks fixed permanently without costly, disruptive excavation—using pressure injection of epoxy resin or polyurethane water stop foam repair materials.

Many Concrete Block Walls Leak

You may find damp areas in your block wall or even active leakage from grout lines in your wall. Check the perimeter of your wall and the cold joints where the wall meets with the foundation or floor for leaks. Fresh concrete does not bond well to existing concrete – a cold joint is created. If not properly waterproofed, a cold joint will be a passageway for water migration.

In many cases homeowners can have these cold joints fixed permanently without costly, disruptive excavation—using basement waterproofing products such as pressure injection polyurethane water stop foam and leak-seal injection repair materials.

We offer Do It Yourself Kits for Basement Leak Repair

Polyurethane and epoxy injection are water stop, leak seal and structural repair systems used by thousands of applicators world wide. Basic product knowledge helps users and specifiers to reduce possible problems. The right injection technology should be identified before the project is started. This brief overview is designed as a basic guideline for your decision making.

SealBoss products have been developed for professional use and commercial applications. It is advised that product knowledge and product application knowledge is necessary for good success. It is our recommendation for homeowners to have basement repairs performed by a professional applicator.

We have received many testimonials over the years from savvy homeowners that have performed the repairs themselves after studying the product and procedure prior to application.

We encourage you to call with any questions you might have. Our technical staff will gladly assist you with your projects.

Distributors for Selected Sealboss ® Products

– Dependable Depot, Inc.

– Instant P.O.

For Professional Use

Shipping to USA & Canada

Basement Waterproofing Products

Do-it-Yourself Products

Residential Basement Applications

Professional Basement Waterproofing Systems for Homeowners

Basement Repair Systems

Basement Water Stop Foam & Leak Seal Crack Repair - Polyurethane Foam Injection

Basement Structural Wall & Foundation Crack Repair Kits - Epoxy Injection

Basement Floor Repair Kits & Floor Joint Fill Kits

DIY Repair System Testimonial

Just wanted to say how glad I was to have your product on Monday. I live in Cobb County, GA and the water came pouring in during our recent flooding. I had already actually patched one of my two retaining wall cracks and already had the holes drilled for the second. However, I had not pumped the second one, so I got a desperate call from my wife for help when the rain hit that critical point and water stacks up against the front of our house. I got there from work as quickly as I could and still had to tighten the packers and mix the resin, but I had the water stopped inside of 15 minutes and we got nothing wet except for a few towels! What a lifesaver! There are a couple of areas that I just could not get the foam into so I am going to have to drill a few holes to make certain everything is sealed. I will need to order a few more more packers for that. I have bragged to many guys here at work about the DIY system and several have asked for your info for themselves or others, so I have passed your website along to quite a few already!

Thanks Again

SealBoss Products and Services

COVID-19 Related Update

Dear Valued Customer:

We at SealBoss Corp. would like to provide you with current information as it relates to our continuity planning, inventory and supply chain in light of the Novel Coronavirus.

At this time, we do not anticipate delays or shortages in our current supply of our main product lines as a result of COVID-19. As always, our sales and technical staff is focused on delivering the levels of service you expect from SealBoss.

As much as the continuation of business is important to us, our main concern is the health of our employees, customers, partners and their families. SealBoss is following the guidelines of the Government Agencies, Centers for Disease Control and Prevention (CDC) and World Health Organization (WHO).

SealBoss implements all recommendations at the work place and technical sales representatives work from home offices across the country.

As we all have to adapt to the changing conditions in this current environment, we at SealBoss Corp., and with the dedicated support of our affiliates and distributors, will do our best to meet your needs and expectations.

Please let us know how we can be of service. Call us at 714-662-4445.

We wish you and your families continued good health and well-being.

Sincerely,

SealBoss Team

SealBoss Injection Guideline Part 1

Injection Guideline Part 1

Injection Guideline for Water Stop & Leak Sealing Applications

Choosing Your Products for Water Stop & Leak Sealing Injection

Choosing the product with the correct properties for the job is the first step to a successful and long lasting leak seal and crack injection application. Material with the appropriate physical properties simplifies the application and provides for long term durability.

We differentiate between hydrophilic and hydrophobic products which vary in their physical properties, such as viscosity, expansion rate, reaction time, flexibility, density and hardness.

Hydrophobic Chemical Grouts

SealBoss 1510/1570/1570LV/1500 polyurethane injection grouts form a group of hydroactive, hydrophobic injection resins, sharing basic physical properties. Water/moisture initiates the reaction only, but the cured product is insensitive to moisture and of a constant volume. Since water is not a component of the foam structure, the cured material is essentially not effected by water or dryness and does not shrink or swell. Products are not effected by freeze/thaw and wet/dry cycles.

SealBoss 1640 Foam & SealBoss 1403 PUR Resin are hydrophobic products that do not require water to react.

Hydrophilic Chemical Grouts

SealBoss FlexGel & SealBoss 2400 Acrylate (Acrylic) Gel are hydrophilic products. Water/moisture initiates reaction and the product is capable of absorbing and incorporating water post cure, thereby swelling and forming a waterproofing flexible gel or foam. Hydrophilic products are recommended for applications in permanently moist environments, curtain/bladder injection, and capillary injection.

Viscosity

SealBoss 1510/1570/1500 Water Stop Foams & Flexgel are of low viscosity for good penetration into concrete cracks and joints. For hairline cracks, capillary fissures and tight cold joints we provide super low viscosity products such as SealBoss 1570LV Water Stop Foam, SealBoss 1403 PUR Resin, SealBoss 2400 Acrylate (Acrylic) Gel.

Accelerator Adjustable Hydro Active

Expansion & Reaction Time

The reaction times and expansion rates of SealBoss 1510/1570/1570LV Water Stop Foams are adjustable by adding a specific amount of SealBoss accelerator. The gel times of SealBoss 1403 PUR Resin & SealBoss 2400 Acrylate (Acrylic) Gel are also adjustable.

The reaction time and expansion rate of a foam determine the water stop and penetration properties of the product.

Faster reaction times and expansion benefit water cut-off properties, slower reaction times enhance product penetration in the substrate.

Water-reactive polyurethane grouts expand on contact with water by the resulting CO2 gas. The foam expansion creates a compression seal which supports the sealing properties of the injection grout.

Rapid expansion helps to cut-off high-volume active water leaks and benefits curtain/bladder grouting. The expansion rate of a foam determines material consumption, cell structure and density of the cured product. It should be considered that expanding foams can create a significant amount of pressures.

Our best-selling, industry standard SealBoss 1510 Water Stop Foam, can rapidly expand between 5 to 50 times (50X) of free rise product volume when catalyzed accordingly.

Flexibility & Density

For most injections in joints, cracks and some curtain/bladder wall grouting that do not experience much movement, semi flexible standard products with high expansion rates and higher compressive strengths such as SealBoss 1510 Water Stop Foam, SealBoss 1500 2-Component Water Stop Foam are used.

Structures exposed to thermal expansion and contraction or dynamic loading resulting in increased movement may require a flexible formulation grout such as SealBoss 1570/1570LV Water Stop Foam, SealBoss 1403 PUR Resin or SealBoss Flexgel. SealBoss 1403 PUR Resin is also recommended as follow-up and final seal injection in critical foam injection areas.

Good product density, complete penetration and adequate product consumption make for a successful leak seal injection. Injection pressures must be high enough to provide for good material travel, proper penetration and density.

We recommended to always monitor injection pressures and material flow closely. When done correctly, the high density injection material will form a compression seal and provide for a or a long lasting application.

SealBoss Injection Guideline Part 2

Injection Packer Guideline

How to Select Mechanical Injection Packers

Finding the Suitable Injection Packer

Injection packers and ports play a pivotal role in ensuring successful injections. At SealBoss, we pride ourselves on offering an extensive range of injection packers tailored to meet diverse needs. For those new to the field, selecting the ideal packer can seem overwhelming. To assist you, we’ve provided a concise overview of the various packer types and their unique features. Our collection encompasses a variety of designs, taking into account factors such as Packer Material Type, Diameter, Length, and Ball & Valve Location. Dive in to discover the perfect packer for your requirements.

Packer Material Type

Mechanical Injection Packer Body

SealBoss mechanical packers are made from different material including steel, brass, aluminum, zinc, various metal alloys and plastic. There are important differences in design and functionality for a variety of products, substrates and objectives. Contractor preferences and comfort levels are also a deciding factor.

Steel Injection Packers

SealBoss offers many heavy-duty steel packer variations. Steel offers the most strength and good resistance to oxidizing components found in acrylate/acrylic gels. SealBoss offers a wide variety of steel packers to suit all injection needs. Most packers are equipped with a rubber sleeve, some have a larger washer on the top of the packer to assist in the installation.

Brass , Aluminum, Zinc Injection Packers

Brass, aluminum & zinc packers are economical alternatives to steel packers with similar functionality. The overall strength is lower than steel, brass, zinc and aluminum packers bodies are softer. In some designs, the shaft can be broken off by hammer after injection thus leaving a flush surface. This is an advantage if removal of packer prior to patching is not specified.

Plastic

Plastic Injection Packers

Some permit low resistance, high volume product flow and very quick installation.

Button Head / Button Top Injection Packers

The SealBoss 5/8” (16mm) Button Head packer offers high volume flow with a button head (button top) coupler to minimize leakage. Insert the plastic sleeve in the drill hole and thread the plastic packer into the sleeve for a compression fit via the hex button head. Anti return valve: A steel ball placed in the shaft of the packer prevents product back-flow.

Hammer-In / Bang-In Injection Packers

The SealBoss Hammer-In port (Bang In Packer) is 3/8” (10mm) or 1/2” (13mm). The ports are inserted into the drill hole with the tap of a hammer. The plastic body of the packer creates a compression seal. The packers are set very quickly increasing productivity on the job site. Due to the lower friction fit, injection pressures are limited with this packer type.

Packer Construction Variations – Diameter, Length, Valves, Diameter

As a rule, and in addition to the packer material, a larger mechanical packer diameter permits higher injection pressures. 5/8” (16mm), ½” (13mm), 3/8” (10mm) and 1/4” (6mm) are most common diameters for man made structures, larger diameters are mostly utilized in rock and other natural structures. Caution: Packers and ports can exit the drill hole at high velocities under pressure. Correctly installed packers of the right dimensions will minimize this probability. In general, larger diameter packers prevent blow-out better than smaller packers.

Originally from Baltimore Maryland, Ben Ball has been working in the concrete repair industry for over a decade. He has worked on the repair, waterproofing and strengthening of structures ranging from high-rise condominiums to underground concrete vaults.

Originally from Baltimore Maryland, Ben Ball has been working in the concrete repair industry for over a decade. He has worked on the repair, waterproofing and strengthening of structures ranging from high-rise condominiums to underground concrete vaults.