Rocking Concrete Slab Repair

Rocking Concrete Slab Repair

Rocking Concrete Slab Repair & Stabilization

Concrete Leveling may be Your Best Alternative to Replacement

Fast and Minimally Invasive

No Excavation

Cost Effective

Stabilize Soils

Rocking Concrete Slab Repair:

Addressing Rocking Slab Issues Efficiently

Rocking concrete slabs, often observed in warehouses, not only present damage risks to forklifts and equipment but also endanger the safety of warehouse employees.

An Innovative Solution: SealBoss Polyurethane Foam Jacking

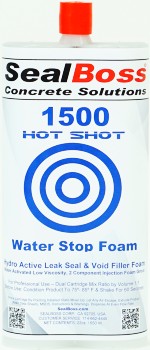

SealBoss polyurethane foam jacking and lifting solutions are ideal applications for stabilizing, void filling, and re-leveling of concrete slabs.

The essence of slab lifting and stabilization lies in addressing unstable concrete slabs that have sunk due to various factors, such as aging, improper installation, soil conditions, or erosion. The repair is performed with a dual-component structural polyurethane injection foam. This foam seamlessly fills the voids beneath the slab, expanding to form a sturdy and lasting support structure.

The Process Explained

Here’s how it works:

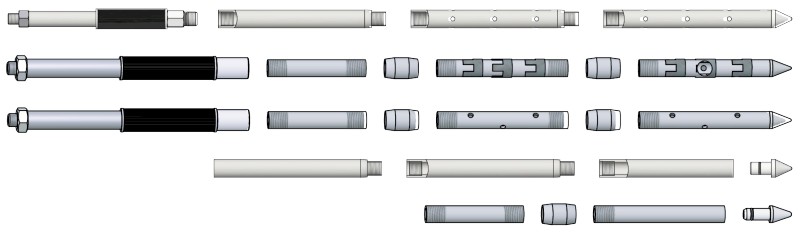

In this smaller job showcased here, SealBoss 1640 Structural Foam and the very lightweight and affordable SealBoss P3003 two component injection pump were used.

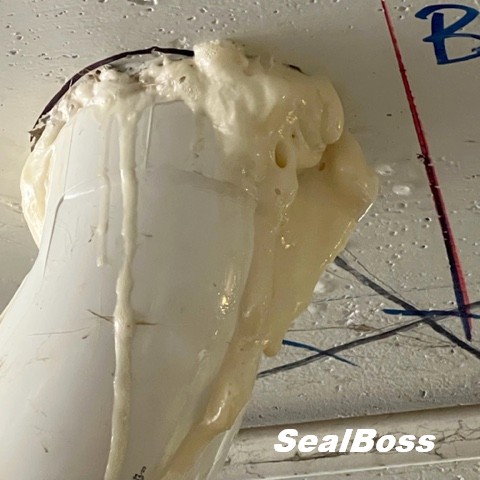

Small holes are drilled through the concrete slab. High-density PUR foam is then injected through these holes, commencing the foam’s expansion while simultaneously filling the voids beneath the concrete.

As the foam expands, it lifts the slab, aligning it perfectly with the neighboring slabs. An added benefit is that any water trapped underneath gets displaced, negating potential future water damage.

Choosing this method over concrete replacement not only saves on costs but also provides a swifter, cleaner, and less intrusive solution.

Best of all? Once the process is complete, the stabilized concrete slabs are prepared to handle traffic in just about 30 minutes.

The Top Benefits Of Polyurethane Concrete Slab Lifting and Void Filling

- Quick Process and Cost Effective

- Accurate Lift to Match Adjacent Slabs

- Easy Access via Pump / Hose System

- Filling voids and Stabilizing Soil

- No Expensive Concrete Replacement

- No Damage to Landscape

- Moisture Proofing

- Multi-Use – Lift and Stabilize Slabs, Foundations, Stairs, Driveways

- Marine Use – Sea Walls, Docks, Bulkheads

If you have any questions on Rocking Concrete Slab Repair, or any of our product lines and applications, please contact our team of qualified SealBoss representatives.

Schedule an on site consultation & full injection systems training.

Call us at 714-662-4445.