Concrete Joint Sealing and Sheet Piling Caulk Applications with SealBoss Swell Caulk Joint Sealer

SealBoss® Swell Caulk Joint Sealer is a high-performance, single-component, hydrophilic, gun-grade waterstop caulk engineered to deliver a dependable, hydro-active compression seal across a wide spectrum of demanding construction environments. Its advanced formulation activates upon contact with water, creating an expanding, watertight barrier that enhances the integrity and durability of concrete structures by actively blocking water pathways.

Unlike passive sealants, this swellable caulk develops expansive pressure against the surrounding substrate, effectively filling gaps and voids to prevent any water ingress.

The result is a durable waterproofing solution that outperforms conventional caulks in below-grade and water-exposed conditions.

In practical terms, SealBoss SwellCaulk offers the adaptability to be used where traditional waterstop strips or gaskets might not be feasible. Its thixotropic (non-sag) consistency allows application on vertical or overhead surfaces without running, and it conforms to irregular profiles that solid waterstop strips cannot tightly seal.

After curing, typically within 24–36 hours under normal conditions, the material exhibits excellent elasticity and bond strength, forming a long-lasting seal that accommodates slight movements and settlements in the structure.

This combination of ease-of-use and robust performance makes SwellCaulk equally suitable for new concrete construction joints and for remedial sealing of existing leaking joints or penetrations.

Expanded Applications of SealBoss® Swell Caulk Joint Sealer

The versatility of SealBoss® Swell Caulk Joint Sealer makes it ideal for a broad range of below-grade and water-exposed construction details, including but not limited to:

- Construction joints and Cold joints

Cold joints and seams in concrete (e.g., between pours in foundation slabs and walls) - Pipe and conduit penetrations

Around utility pipes, electrical conduits, and other services passing through concrete structures

- Manhole and catch basin connections

Interfaces in sewer systems, storm drains, and precast manhole sections

- Precast concrete segments

Joints between tunnel segments, box culverts, and other precast elements

- Expansion joints

As a waterstop accessory in joints that require waterproofing while accommodating flexibility

- Tunnel segment interfaces

Gaskets for segments in tunnels or shafts, improving water tightness at segment rings

- Sheet pile interlocks

Sealing the female interlock (knuckle) of steel sheet piles to prevent seepage through cutoff walls and cofferdam - Poured concrete wall structures, ties and seams

Construction joints in retaining walls, basement walls, etc., where water seepage must be prevented

- Below-grade and basement walls and retaining structures

Where walls meet floor slabs or footing interfaces

- Water tanks and wastewater treatment structures

Joints in concrete tanks, clarifiers, reservoirs, and containment basins - Utility vaults and cable duct entries

Sealing around precast vault sections and where cables or conduits enter vaults

Whether you’re working with smooth or rough substrates, this caulk adapts effectively, delivering consistent performance. When exposed to moisture, it swells intelligently to create a high-pressure, watertight seal, without exerting excessive force on adjacent concrete or structures.

This optimized swelling action means it won’t crack or dislodge young concrete – Swell Caulk is even suitable for green (freshly poured) concrete applications, as the expansion rate is calibrated to avoid damaging the curing material.

Because SealBoss SwellCaulk remains flexible after curing, it can accommodate minor movements or shrinkage in the joint while maintaining a seal, and it will re-swell in cyclic wet/dry conditions to continually self-seal if water is reintroduced.

Unlike rigid waterstop strips, the gunnable SwellCaulk can be applied into odd-shaped cavities and around complex penetrations that preformed strips cannot seal as effectively. This makes it a highly versatile waterproofing tool across many construction scenarios.

Sheet Pile Interlock Sealing

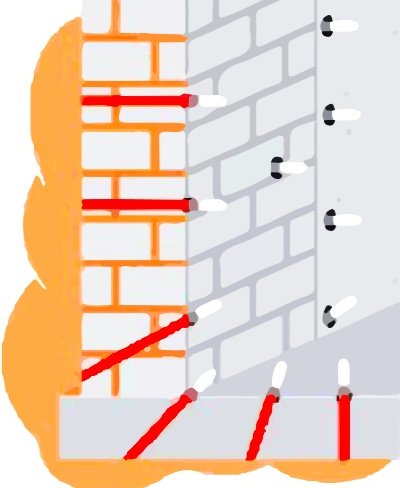

In sheet pile applications where watertight integrity is crucial, SealBoss® Swell Caulk Joint Sealer is specifically formulated to be gunned directly into the female interlock (knuckle) of the sheet pile before driving. This technique ensures the formation of a continuous, compressible barrier between interlocked sections—effectively sealing against groundwater intrusion and vastly improving the performance of retaining walls, cofferdams, and flood protection systems. As each sheet pile is driven, the pre-applied bead of SwellCaulk is compressed within the interlock, and upon contact with water it swells to form a tight gasket, blocking any seepage through the interlock seam.

The product’s robust adhesion and expansive swelling action fills micro-voids and irregularities inside the interlock, dramatically increasing resistance to hydraulic pressure through the joint. Once confined and activated, the swollen seal can withstand significant hydrostatic pressure without leakage. This level of performance provides confidence that even under high groundwater or hydrostatic load, the sheet pile wall will remain watertight.

Installation Note: The applied SwellCaulk should be protected from rain and water exposure prior to driving the piles to prevent any premature swelling of the sealant. In practice, contractors will cover the caulked interlock if rain is expected, ensuring the material stays dry until the sheet piles are in place. Once the piles are driven, the sealant must be fully confined within the interlock on all sides to perform as designed. Proper confinement allows the expanding caulk to build up internal pressure against the steel surfaces, rather than pushing outward. By adhering to these precautions, the result is a continuous, reliable waterstop along the entire length of the sheet pile wall.

Adhesive for SealBoss® Swell Tape Integration

Another key application is its role as a recommended adhesive for the SealBoss® Swell Tape system, a popular waterstop solution used in combination with bentonite and polyurethane-based swelling tapes. This hybrid solution harnesses the strengths of both products — Swell Caulk and Swell Tape — providing an integrated waterstop system ideal for high-performance sealing of complex concrete structures, including joints with variable geometries.

Using SealBoss SwellCaulk as an adhesive offers several advantages. It improves tape placement accuracy by holding the strip firmly exactly where needed, even on vertical or overhead surfaces. The caulk’s excellent adhesion to concrete, steel, and plastic means the Swell Tape will not shift during concrete placement or in the time before water activation.

Furthermore, the caulk forms a continuous bedding layer behind the tape, which helps to seal uneven substrates; for example, on rough concrete, SwellCaulk fills voids that might otherwise leave a leak path under a plain tape. When water does reach the joint, both the tape and the caulk swell together, creating a dual-layer expansion that ensures any leakage path is quickly closed off.

By combining a swellable caulk with a swellable tape, the system harnesses the strengths of both products: the caulk provides instant adhesion and seals small gaps or surface imperfections, while the tape adds volume and a second layer of swelling action.

This integrated waterstop system is ideal for high-performance sealing of complex concrete joints, including joints with variable geometries or rough surfaces that might challenge a sole waterstop strip.

Application Guidelines

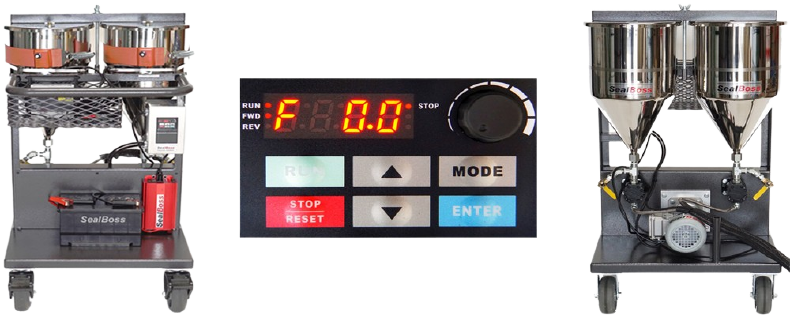

To maximize effectiveness, SealBoss® Swell Caulk Joint Sealer should be applied using a standard caulk gun directly into the joint or void area to be sealed. It is ideal for:

- Construction joints in foundation walls and slabs

- Pipe and steel penetrations through floor slabs and walls

- Tunnel and segment joints in underground infrastructure

- Precast structure connections and segmental retaining walls

- Cold joints in cast-in-place concrete elements

- Utility duct entries and around embedded elements

Allow the material to cure appropriately before concrete placement or water exposure, following SealBoss® product guidelines for optimum results.

Key Benefits of SealBoss® Swell Caulk Joint Sealer

SealBoss® Swell Caulk offers a host of technical and practical advantages over conventional joint sealing solutions:

- Single-component formulation

Easy to apply with minimal preparation and equipment. - Time and labor savings

Faster application compared to multi-part systems, reducing on-site costs. - Water-reactive expansion

Hydrophilic polymer swells upon contact with water, forming a pressure-tight seal. - Safe for fresh concrete

The controlled expansion does not damage surrounding concrete during curing. - Excellent substrate adhesion

Bonds to a wide variety of construction materials, including concrete, metal, PVC, and more. - Durable and flexible

Withstands cyclic wet and dry conditions without losing performance. - Eco-conscious formulation

Low VOC and environmentally friendly, contributing to sustainable construction goals. - Cost-effective

Combines ease of use with performance, reducing material waste and installation errors.

A Reliable Solution for Demanding Construction Environments

SealBoss® Swell Caulk Joint Sealer is more than just a caulk—it’s a proactive water management solution that strengthens structural reliability across a wide array of projects. From infrastructure and utilities to commercial buildings and environmental containment, its hydrophilic technology ensures consistent, long-term waterproofing performance.

The technology behind SwellCaulk represents a significant advancement in joint sealing strategies. Traditional methods like passive sealants or physical waterstop inserts can be limited by installation challenges or eventual wear. In contrast, a hydrophilic swelling sealant remains dormant until needed and then actively engages to block water, which means it’s on guard for the life of the structure. This kind of reliability in wet or aggressive environments (such as wastewater plants, underground parking garages, or tunnel linings) reduces maintenance needs and extends the service life of the construction. Structures protected with SwellCaulk and its companion products are less likely to experience leaks, even decades into service.

Whether you’re building new structures or reinforcing existing ones, incorporating SealBoss® Swell Caulk Joint Sealer into your project ensures protection against water intrusion, minimizing maintenance and extending service life.

Conclusion

SealBoss® Swell Caulk Joint Sealer represents a significant advancement in waterstop technology. Engineered for reliability, ease of use, and adaptability, it provides a proven solution for challenging sealing applications—particularly in wet or moisture-prone environments.

By integrating this high-performance product into your construction or remediation strategy, you ensure not just a temporary fix, but a long-lasting, hydro-active defense system for your concrete structures.

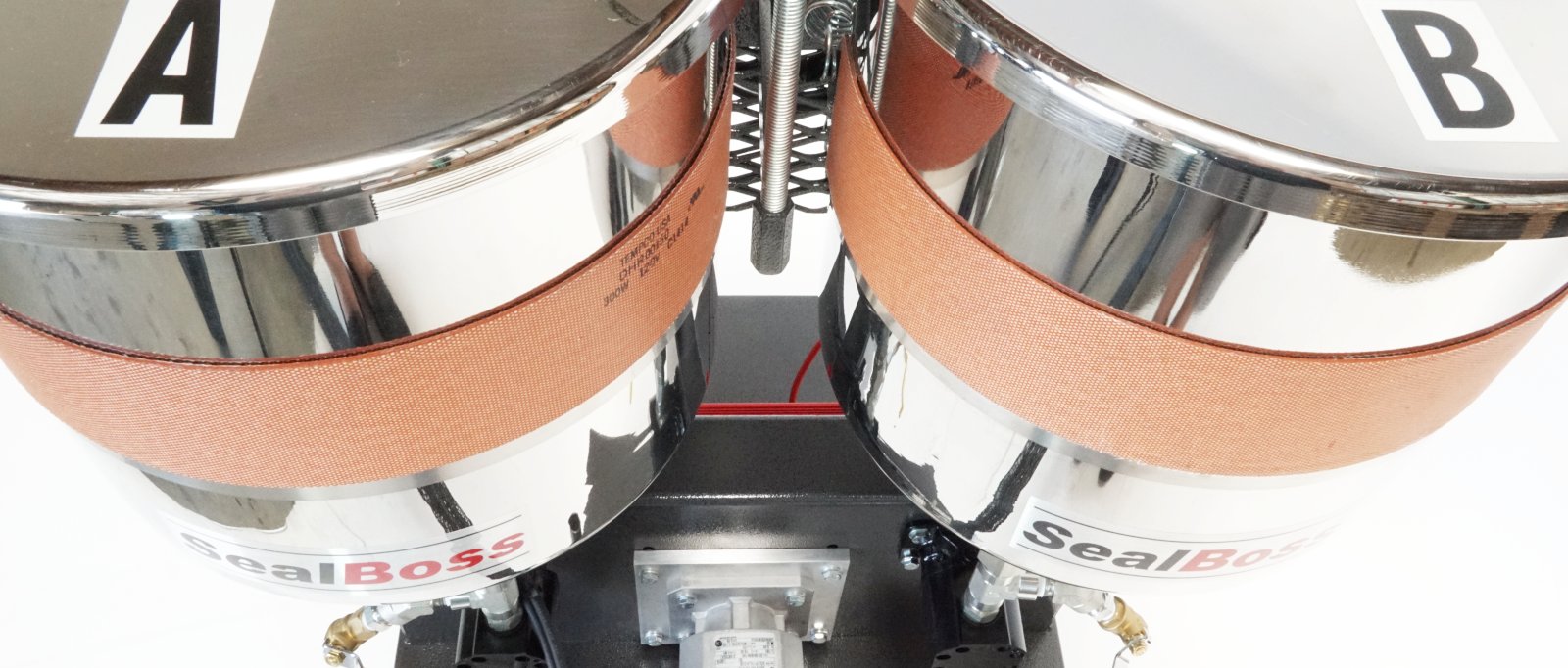

For optimal results, pair SealBoss® Swell Caulk Joint Sealer with other compatible SealBoss® products, and always follow the manufacturer’s installation guidelines.

Trusted by engineers, contractors, and builders worldwide, SealBoss® helps you build with confidence — below grade and beyond.