The Detrimental Effects of Water on Concrete Structures

Water migration in concrete parking garages can lead to corrosion, compromising the structural strength of the concrete, increasing the likelihood of further cracking, spalling, and in severe cases, complete structural failure. These issues not only present significant safety hazards but also accelerate the need for increasingly extensive repairs.

Recognizing the Signs of Structural Compromise

Early detection of water-related damage is critical for the longevity of parking structures. Key indicators include cracking, spalling, efflorescence (a greyish white, powdery substance indicating water movement within concrete), and rust stains on concrete surfaces. These signs point to potential rebar corrosion and overall weakening of the concrete structure.

Immediate and Long-Term Waterproofing Actions

Effective waterproofing requires both immediate interventions and long-term strategies.

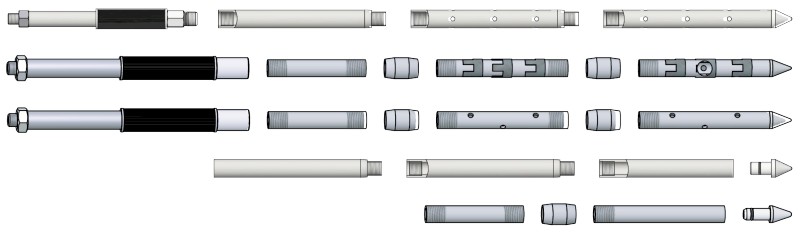

Immediate actions often include sealing leaks with polyurethane polymer grout or acrylate grout injection and allowing for additional drainage to prevent water accumulation.

Long-term measures involve regular structural inspections and the development of comprehensive maintenance plans, encompassing routine cleaning of drains and re-application of waterproofing materials.

Protecting Investment and Public Safety

The integrity of below-grade parking garages is crucial for the safety of its users and the preservation of asset value. Stakeholders need to understand the impacts of water damage and adopt proactive strategies to mitigate risks. This approach helps extend the lifespan of parking structures, reduces maintenance costs, and ensures a safe, functional environment for users.

Maintenance of Drainage Systems

Effective drainage is paramount in preserving the structural integrity of parking garages. Poor drainage can lead to water ponding, increasing slip-and-fall risks, and accelerating concrete deterioration. Maintaining an efficient drainage system is thus essential for avoiding frequent and costly repairs.

Contractors tasked with improving drainage should focus on optimizing the existing system. This involves evaluating the system’s effectiveness, cleaning drains, removing debris, and recommending a schedule for regular inspections and ongoing maintenance.

While improving drainage systems may require an upfront investment, the long-term benefits, including reduced maintenance costs, structural preservation, minimized safety risks, and enhanced operational efficiency, are substantial.

Combating Corrosion

Water migration of any source, including groundwater, rain water and sprinkler runoff, and environmental factors like minerals and vehicle emissions can significantly corrode concrete and metal components. Polymer grout injection, when correctly applied, effectively seals against these elements, prolonging the garage’s structural integrity.

Cost Considerations and Long-Term Value

Investing in polymer grout application, including hydro-active foam, polymer gels and resins, is cost-effective in the long run, offering benefits such as reduced repair costs, extended lifespan of the garage, enhanced safety, and increased property value.

Complementing Polymer Grout Technology with Other Preventative Measures

A comprehensive corrosion prevention strategy can include additional measures like proper ventilation, regular cleaning, and the application of specialized coatings and sealants, alongside polyurethane grout injection methods.

Regular inspections and proactive maintenance are key to sustained effectiveness in corrosion prevention. Any signs of new corrosion should be promptly addressed to maintain the structure’s integrity.

The Importance of a Comprehensive Corrosion Prevention Strategy

A holistic approach to combating environmental corrosion is essential for the long-term success of waterproofing efforts. This strategy should encompass quality application of polyurethane grout and integration into a broader corrosion prevention plan.

Sealing of Gaps and Spaces Around Electrical Conduits and Pipes

Moisture poses significant risks to electrical systems within parking garages, potentially leading to hazards such as short circuits and electrical fires. Ensuring electrical safety requires a multifaceted approach that can combine polyurethane grout application with other comprehensive safety measures. This strategy is vital for reducing the risks associated with water infiltration.

Polyurethane grout is instrumental in mitigating these risks by effectively sealing areas around electrical installations and sealing of leaking conduits and the sealing of other openings in the structure such as annular spaces and gaps around drainage pipes.

The initial investment in polyurethane grout application for electrical safety and the sealing of conduit and pipe penetrations pays off in the form of reduced maintenance costs, enhanced safety, and operational continuity. Electrical, conduit, and pipe penetration safety in parking garages should include regular inspections and maintenance.

Conclusion

Waterproofing below-grade parking garages is a critical aspect of urban infrastructure maintenance. By understanding the challenges, recognizing the signs of damage, and implementing both immediate and long-term waterproofing strategies, owners and stakeholders can protect their investments, ensure public safety, and maintain the structural integrity of these essential facilities.

Regular maintenance, combined with the strategic use of preventative and repair materials like polyurethane grout, forms the cornerstone of effective waterproofing and corrosion prevention.

For specialized solutions, consulting with the waterproofing experts at SealBoss Corp. is recommended to ensure that your parking garage remains safe, functional, and valuable for years to come.

Related Links

Structural Parking Garage Repairs

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.