Utility Vault Leak Sealing Repair

Utility Vault Leak Sealing Repair

Utility Vault Leak Sealing Repair

Injection Technology for Utility Vault Repair and Maintenance

Introduction:

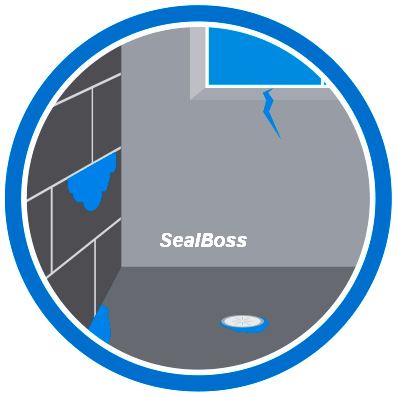

Utility vaults, integral components of modern infrastructure, house essential services like electrical and telecommunications equipment. Despite their robust construction, they are prone to leaks, especially at precast joints and pipe penetrations. Neglecting these leaks can lead to operational, safety, and financial challenges. This comprehensive guide delves into the intricacies of utility vault leak sealing repair, emphasizing the application of polyurethane grout for long-lasting solutions.

Advantages of Polymer Grout Injection for Utility Vault Leak Sealing Repair

Polyurethane grouts stand out for their material longevity and flexibility after curing, accommodating structural shifts and reducing the likelihood of cracks. Economically, it requires fewer reapplications and offers reduced labor costs, making it a cost-effective choice in the long run. Environmentally, SealBoss’s NSF-certified polyurethane grouts meet stringent public health and safety standards, ensuring minimal impact on the environment.

Acrylate / acrylic gel injection resins offer extreme penetration properties and super low viscosity and are used for permeation and curtain injection while providing a sealing membrane in blow grade structures between the concrete and surrounding soil.

Utility Vault Leak Sealing Repair

Ensuring Structural Integrity and Operational Efficiency

The Consequences of Ignoring Leaks

Unaddressed leaks in utility vaults can lead to equipment corrosion, failure, or increased maintenance needs, affecting the reliability of utility services. Moreover, water in electrical vaults creates a hazardous environment, increasing the risk of electrical short circuits and posing a safety threat to maintenance staff.

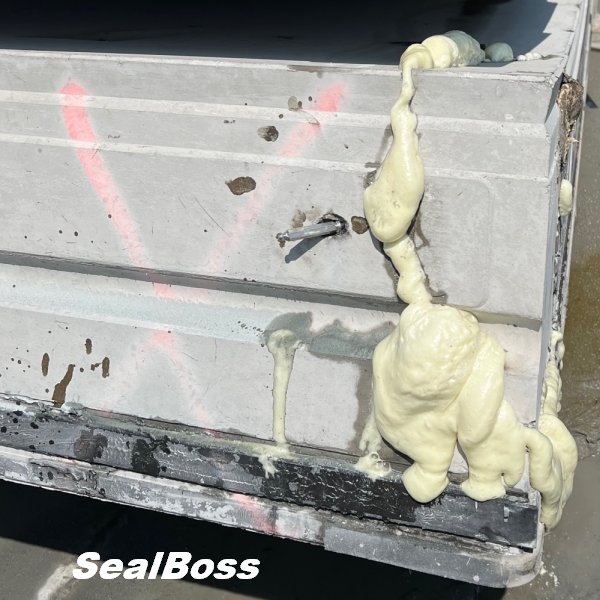

The Solution: Polymer Grout

Polyurethane grout, with various physical properties and reaction profiles, including hydrophobic and hydrophilic formulations, offer highly specialized solutions and a professional approach to sealing leaks in utility vaults permanently. On large and damp concrete walls of damp acrylate / acrylic gel injection may be the application method of choice.

Polymer grout injection most often outperforms traditional methods like cementitious grouting by accommodating structural movements, active high velocity water flow, and preventing leak reoccurrence.

Sealing General Leaks and Leaking Cracks

Leaks can occur due to a variety of reasons including poor construction, soil movement, and aging materials. Cracks in the walls or floor of the vault can develop over time, leading to water ingress.

Crack Injection Method

Crack injection is a precise technique used to address leaking cracks. This method involves injecting a sealing material, typically a polyurethane (or sometimes epoxy resin), into the cracks to create a waterproof barrier.

Steps for Crack Injection:

- Identifying and Cleaning the Crack: The first step is to thoroughly inspect the utility vault and identify all the cracks. These cracks need to be cleaned to remove any debris or contaminants.

- Installing Injection Ports: Small injection ports are then installed along the crack at regular intervals. These ports will serve as entry points for the injection material.

- Injecting the Resin: The selected resin is then injected into the ports, starting from the lowest port and moving upwards. The resin fills the crack completely, creating a waterproof barrier.

- Curing and Finishing: Once the injection is complete, the resin is allowed to cure. After curing, the injection ports are removed, and the surface is finished as required.

Sealing Damp Walls with Curtain Injection Technique

Damp wall and water seepage with very fine cracks or no visible cracks. This issue is typically due to water seeping through the walls, which can be a result of groundwater pressure, capillary action and porous substrate.

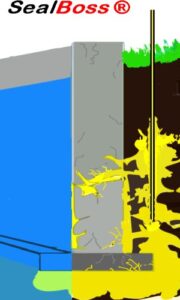

Curtain injection is an effective method for addressing general leaks and damp walls. It involves creating a waterproof barrier behind or around the leaking area. Curtain injection is performed with SealBoss polyurethane grouts or SealBoss 2400 acrylate/acrylic gel resin.

Steps for Curtain Injection

- Assessment of the Leaking Area: A thorough assessment is conducted to determine the extent and source of the leaks or dampness.

- Drilling Injection Holes in Grid Pattern: Holes are drilled into the wall or ceiling at strategic locations to cover the area affected by the leaks or dampness.

- Injecting the Grout: A low-viscosity polyurethane grout is injected into these holes. The grout travels through the voids and cracks behind the wall or ceiling, forming a curtain-like barrier.

- Creating the Waterproof Barrier: The grout permeates and creates a curtain or bladder, sealing off the water paths and creating a waterproof barrier.

- Curing and Inspection: After the injection, the grout is given time to cure. A final inspection is conducted to ensure the effectiveness of the barrier. Curtain injection can often be tested by flooding the area behind the structure.

The Water Migration Problem of Precast Joints and Pipe Penetrations

Precast joints in utility vaults, formed at the junctions between concrete sections, are susceptible to leaks due to cracks, soil shifts or temperature fluctuation caused movement.

Similarly, pipe and conduit penetrations, where utility lines enter the vault, can become leak points. The original sealing around these areas can degrade over time, allowing water to infiltrate the vault.

Repairing Precast Joint Leaks

For precast joint leaks, products like SealBoss 1510 and SealBoss 1570, combined with SealBoss Oakum, offer effective solutions. SealBoss 1570 is a highly flexible polyurethane grout that adapts to movements between concrete sections, while SealBoss Oakum, a special oil-free dry jute rope, helps to seal large and irregular defects when used in combination with the grout.

Installation Guideline

- Clean and moisten surfaces before applying Oakum

- Saturate SealBoss Oakum with SealBoss Polyurethane Resin

- Pack the Oakum into the precast joint and, if necessary, inject additional resin for a complete seal.

- Allow the material to cure overnight

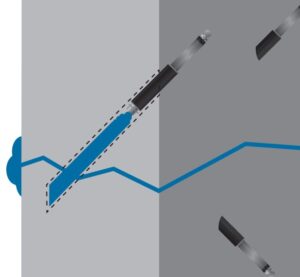

Addressing Pipe Penetration Leaks

For pipe penetration leaks, a combination of SealBoss Polyurethane grout and SealBoss Oakum can create a durable seal. Soaking SealBoss Oakum in the grout and then packing it around the pipe forms a tightly sealed gasket.

Installation Guideline

- Soak SealBoss Oakum in SealBoss Polyurethane Grout and water

- Pack the soaked Oakum around the pipe

- Use a SealBoss Injection Needle to fill any remaining gaps with chemical grout

This method offers longevity, with the potential to last up to five decades.

Selecting a Qualified Contractor

The effectiveness of the repair largely depends on the skill of the contractor. It is crucial to choose a contractor experienced in applying polymer grout. Look for contractors who have received training from the material manufacturer and have a proven track record in polymer water stop injection and leak sealing projects.

Evaluating Proposals

When reviewing proposals, focus on the detailed scope of work, proposed materials, cost breakdown, project timeline, and references. This due diligence ensures that your investment in utility vault leak sealing is well-placed.

Conclusion

Utility vault leak sealing repair, particularly with polymer grouts and resins, is an essential aspect of maintaining infrastructure integrity. Choosing the right contractor and using quality products like those offered by SealBoss can ensure the longevity and effectiveness of the repairs. By addressing these leaks proactively, you can mitigate operational challenges, ensure safety, and avoid negative economic impacts.

Related Links

- Utility Vault Polymer Grouts

- Parking Garage Crack Injection Waterproofing

- SealBoss Seal OAKUM

- Sealing Leaking Conduits

- Sealing Pipe Penetrations

- SealBoss Injection Needles

Structural Utility Vault Repairs

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.