Ceiling Crack Injection Shopping Mall

Ceiling Crack Injection

Shopping Mall

SealBoss ® 1510 Water Stop Foam Ceiling Crack Leak Repair

Job Walk Shopping Mall Los Angeles

A concrete crack in the concrete ceiling in a busy shopping mall was actively leaking. Cracks were described as fine and hairline. A two‑person crew mobilised with SealBoss 1510 Water Stop Foam and SealBoss Packer Evolution 13‑100 AL ports performed a hydroactive polyurethane injection during the designated maintenance window.

Following the repair, a job walk was conducted to inspect the injection site. Correct packer placement was observed and it was, verified that foam had fully expanded, and confirmed that the ceiling was completely dry before reopening the area for traffic.

Injection Procedure

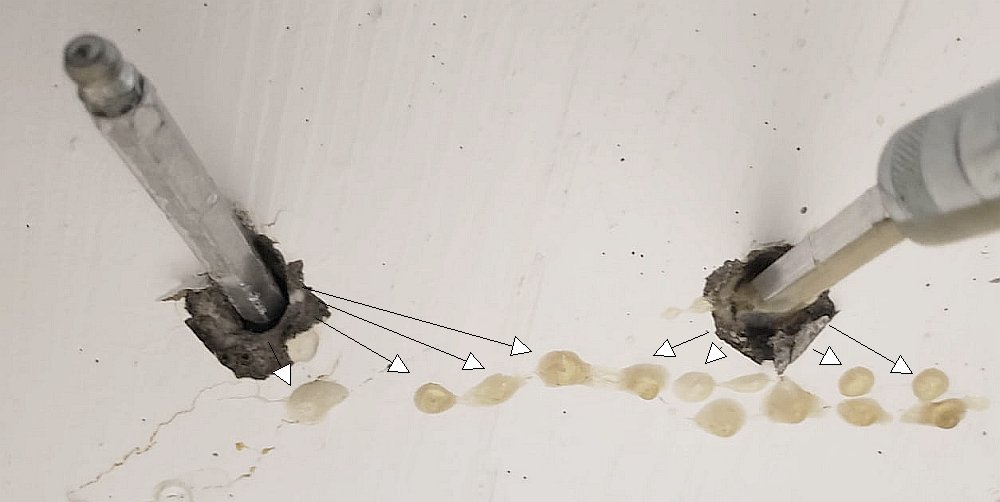

After tracing the crack, technicians marked drill points and hole were drilled at an approximately 45‑degree angle to intersect the crack mid‑depth, then fitted with SealBoss 13‑100 AL packers.

Working from the end showing the strongest water flow, the crew pressurised SealBoss 1510 with the injection pump at up to over 1,000 psi. Resin disappeared into the concrete and re‑emerged at the next packer, or beyond, confirming full penetration. After completing the first pass, they paused to allow the foam to expand, then repeated the sequence. Selected ports accepted a third shot to ensure a dense seal.

Before and after pictures. Ceiling leak repair. Hydroactive polyurethane foam grout injection with SealBoss 1510 Water Stop Foam and SealBoss ® Packer Evolution 13-100 AL.