Understanding Injection Pressures: A Guide to Polyurethane, Acrylate, and Epoxy Repairs

Introduction

Mastering injection pressures is essential for successful concrete crack repair, influenced by crack type, repair material, and environmental factors. Understanding the dynamics of pressure during injection, particularly as it relates to foam expansion and viscosity changes in resins and gels, is essential for professionals aiming to prevent complications such as spalling or insufficient penetration, and ensure a high-quality, lasting repair.

This guide compares the injection pressures required for polyurethane, acrylate, and epoxy materials, providing insights into optimizing repair strategies for improved outcomes

Assessing Injection Pressures and Product Flow:

Comparing Polyurethane, Acrylate, and Epoxy Crack Injection Characteristics

Within the realm of concrete crack injection, the pressures required for a successful repair can significantly vary. This variance is influenced by the specific conditions of the injection environment and the particular products utilized.

The pressures needed to advance the product are governed by the product’s viscosity and the extent of the crack, specifically the resistance the injected substrate presents to the product’s progress.

Generally, it can be stated that narrower, hairline cracks require increased pressure for successful injection, similar to products with greater viscosity.

POLYURETHANE FOAM CRACK INJECTION PRESSURES

In injection jobs involving polyurethane foam and hairline cracks, the necessary injection pressure often leans towards the high side and may exceed 1000 psi under certain circumstances.

During the injection process, when the foam begins to expand upon contact with water, the product’s viscosity increases sharply. This surge can cause back pressure to rise significantly, potentially reaching extreme levels of 1500-2000 psi or higher, depending on the equipment used.

Excessive injection pressure can lead to concrete spalling, a serious risk that may cause additional complications. This underscores the importance of careful handling and precise pressure management throughout the injection process to prevent damage and ensure a successful outcome.

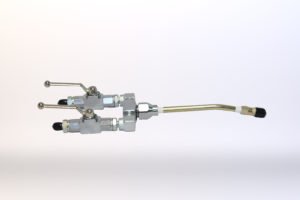

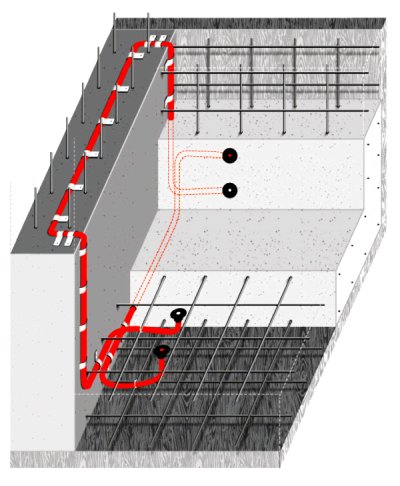

In these instances, it is strongly recommended to avoid setting the injection packers too shallowly. Instead, the use of longer injection packers, capable of reaching more deeply into the drill hole, is advisable.

This strategy serves to minimize the risks associated with high-pressure injection, contributing to a safer and more effective repair process.

In particularly challenging scenarios, it could be a beneficial strategy to think about transitioning to an ultra-low viscosity polyurethane resin, such as SealBoss 1403 SLV – which boasts a viscosity of a mere 70 cps – or consider an Acrylate Polymer.

ACRYLATE POLYMER INJECTION PRESSURES

Alternatively, you might consider an acrylate-based product, like SealBoss 2400 Acrylate, recognized for its viscosity that nearly parallels the low levels observed in water.

These super low viscosity polymers possess the remarkable ability to infiltrate even the finest of hairline cracks with considerable depth. Consequently, they facilitate the formation of a dependable and flexible seal, while reducing the risk of spalling during the process.

Compared to polyurethane injection foams, the exceptionally low viscosity of acrylate gels can provide enhanced penetration capabilities in very tight spaces at lower pressures.

The use of these advanced products can greatly enhance the effectiveness and reliability of concrete repair interventions.

Acrylate Injection Gel is also used for curtain and bladder injection which is mostly performed at lower injection pressures.

EPOXY CRACK INJECTION PRESSURES

Generally, the pressures involved in epoxy injection can be regarded as significantly lower when compared to those utilized in polyurethane crack injection.

SealBoss Epoxy resins are available in both low and super low viscosity grades. These resins maintain a stable viscosity during the injection process and thus allowing an even flow through the crack.

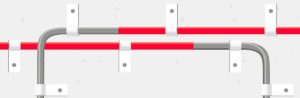

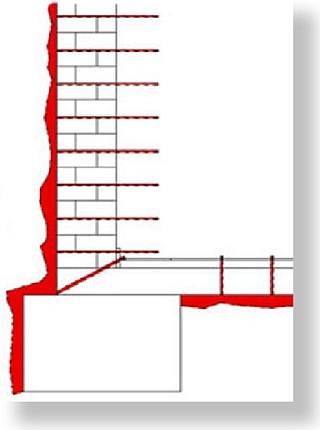

The process of epoxy injection is executed via ports installed on the surface, which are secured onto the crack with an anchoring epoxy paste. This paste also serves to completely seal the crack’s surface. Adhesively attached epoxy ports, along with the epoxy surface seal, are not built to withstand exceptionally high injection pressures.

As long as a consistent product flow is maintained during injection, most epoxy crack injection tasks can be successfully performed at very low injection pressures. These pressures typically do not exceed a few hundred psi at most.

PRO TIP

As you embark on a concrete crack injection job, it’s recommended to start with an exploratory or mock-up injection phase.

During this phase, identify a distinctly outlined, potentially actively leaking crack that extends deep into the structure for the first injection. This initial phase enables the precise estimation of the necessary quantity of material and the required injection pressures.

It is advised to keep close track of the material consumption and make measurements of the injection pressures needed to push product deep into the structure. Monitoring these aspects assists in developing a clearer understanding of the project’s conditions and planning the subsequent injection process more effectively.