Concrete Crack Injection – Polyurethane

Concrete Crack Injection Polyurethane

Introduction:

Maintaining the structural integrity and aesthetic appeal of concrete constructions is crucial for ensuring their long-term durability and functionality. Water intrusion, often through leaking cracks, poses a persistent challenge that can lead to structural erosion, aesthetic damage, and costly repairs if not addressed effectively.

Leaking concrete cracks are a common issue across various types of infrastructure, from residential foundations to industrial facilities and public spaces. Repairing these cracks requires advanced techniques that not only stop water infiltration but also reinforce the structural resilience of the affected area.

Concrete Crack Injection using Polyurethane (PUR) Water Stop Foam Injection is a cutting-edge, economical solution that provides a permanent seal for leaking cracks. Renowned for its versatility and efficiency, this method effectively addresses a wide range of water damage issues, including structural weakening, rust stains, and efflorescence buildup.

In this article, we explore the PUR Water Stop Foam Injection process, highlighting its procedure, applications, and advantages. By adopting this innovative technique, engineers and contractors can maintain the integrity of concrete structures, safeguarding them from further damage while extending their service life against the forces of nature.

How to Seal Leaking Concrete Cracks with PUR Water Stop Foam Injection

Zoo Exhibit Crack Repair — The Gorilla Exhibit at Omaha’s Henry Doorley Zoo was closed for renovations and repairs, including the sealing of concrete cracks that had shown signs of water intrusion, structural erosion, and visible stains from rust and efflorescence.

Concrete crack injection with polyurethane foam resin was the choice of repair to resolve water bearing crack leaks. Crack related damages were located at a walkway under a lofted area with multiple windows and decorative shotcrete structures where gorillas could sit and be viewed by people walking through the exhibit.

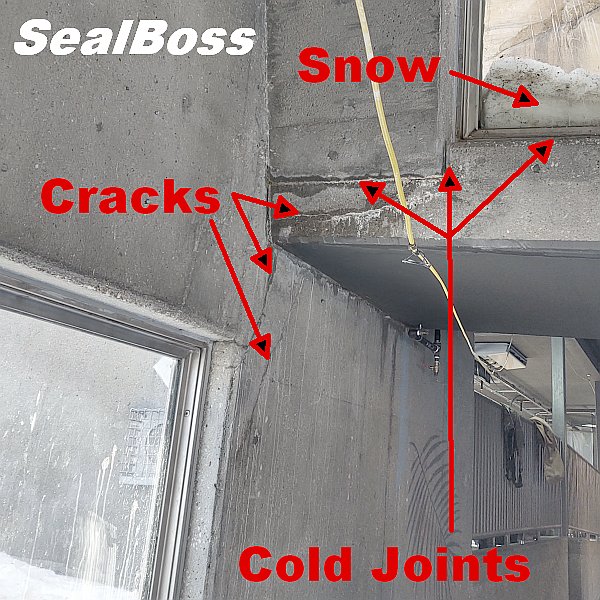

The cracks were covered in efflorescence could be seen on the walls below the lofted area as well as cracks coming off the cold joints around the precast window framing.

The crack dimensions ranged from hairline to 1/4″ joint seams with varying degrees of water intrusion and active leaks causing heavy efflorescence build up. The roof and lofted area collect and feed water during snow melt and heavy rains.

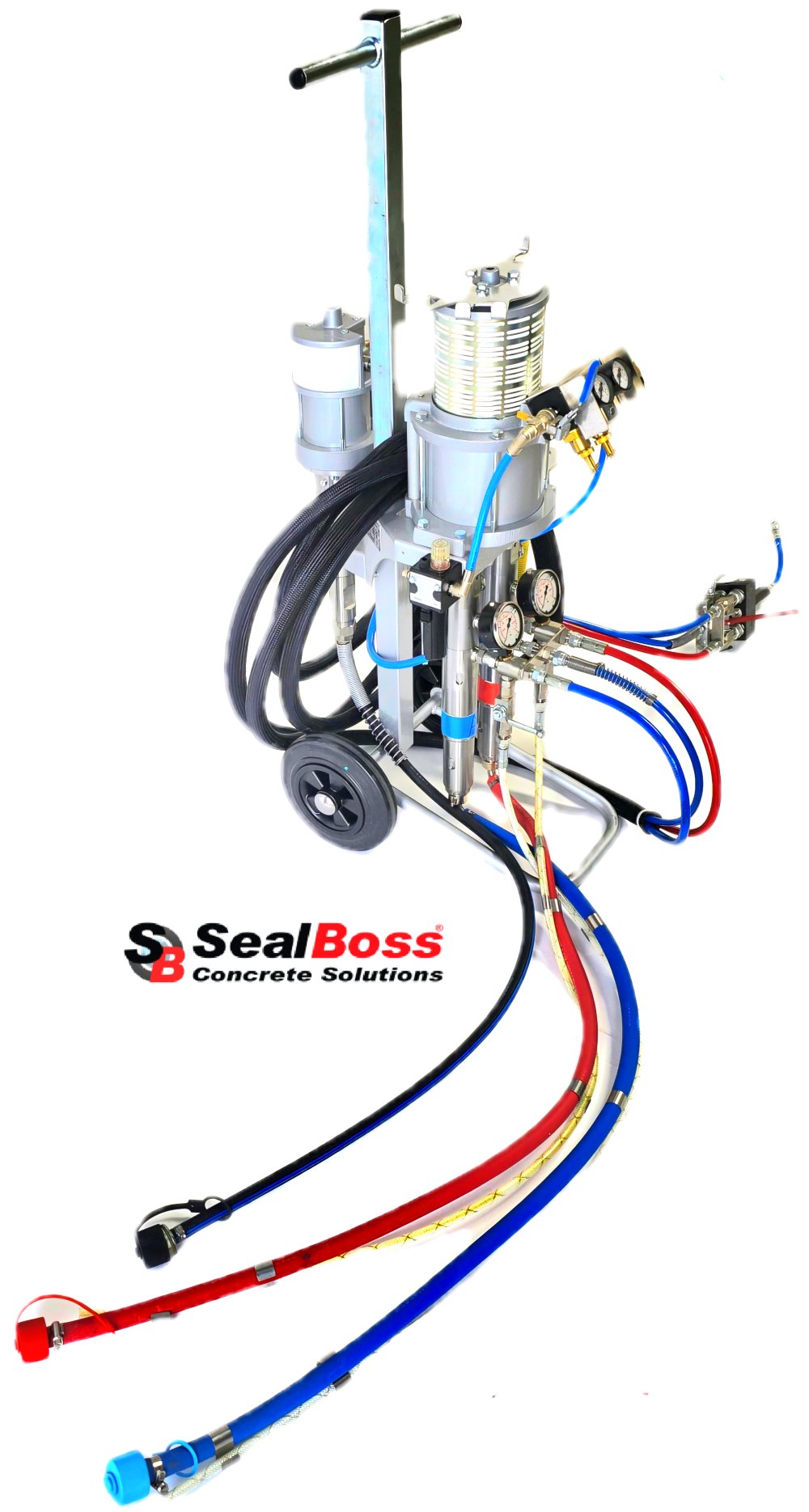

SealBoss provided an on-site technical representative to consult with the contractor on injection methods using NSF/ANSI 61 Drinking Water Contact Certified injection grout, a high-pressure injection pump and mechanical injection packers.

Concrete Crack Injection – Polyurethane

Which products are shown in the video?

- SealBoss Injection Packer Evolution 1/2″ inch (16mm) Aluminum

- SealBoss 1510 Water Stop Foam PU / NSF/ANSI61

Concrete Crack Injection Polyurethane – Procedure and Repair Method

Prior to injection, the contractor had to first prep the cracks by removing any efflorescence and dirt build-up from the face of the crack using a wire brush.

Once the cracks were visible an injection plan was established to address the leaks working from the low point up.

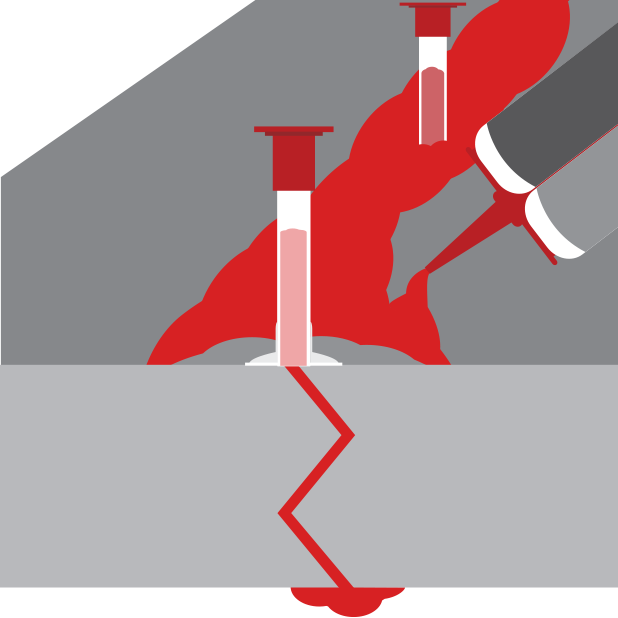

Using the SealBoss high pressure concrete crack injection system — hydro-active, hydrophobic polyurethane foam resin, injection packers and polyurethane crack injection pump — hydro-active foam resin is injected into the cracks, expanding on contact with moisture and displacing any water in the process while creating an airtight & watertight seal.

Crack Injection Details

A – Standard Injection Procedure

One side of the lofted area had three significant cracks that resulted in substantial active leaks. The east wall presented larger actively leaking cracks. Further, cracks and cold joints from a precast window frame created an area of leakage that needed to be injected.

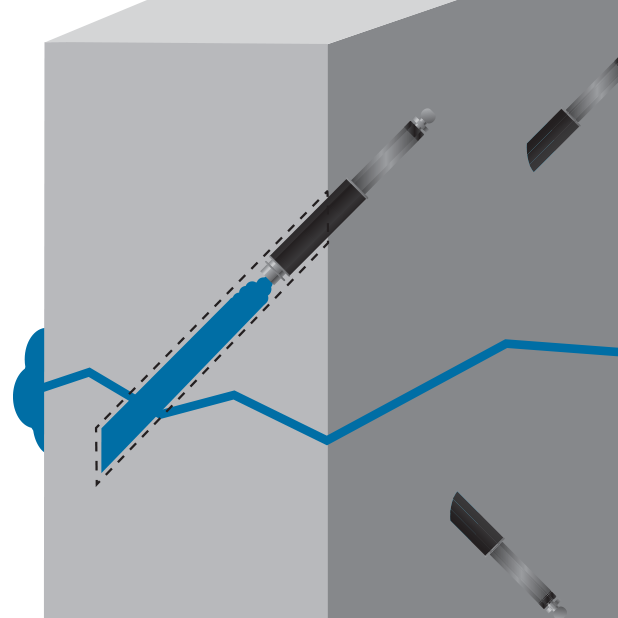

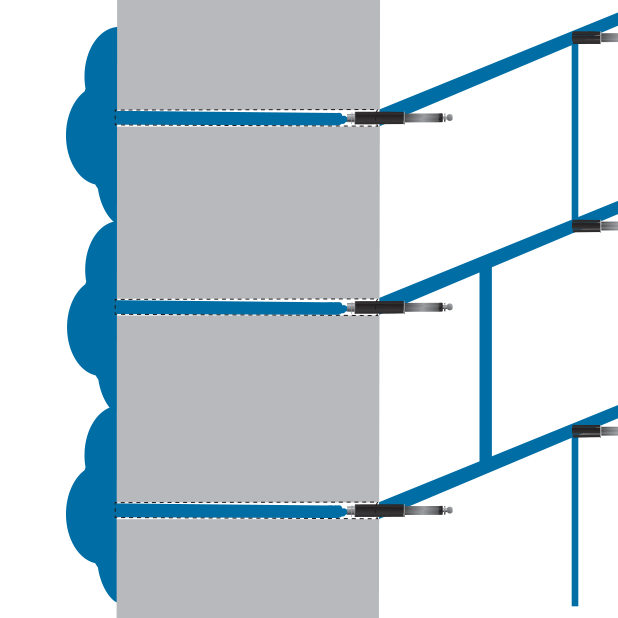

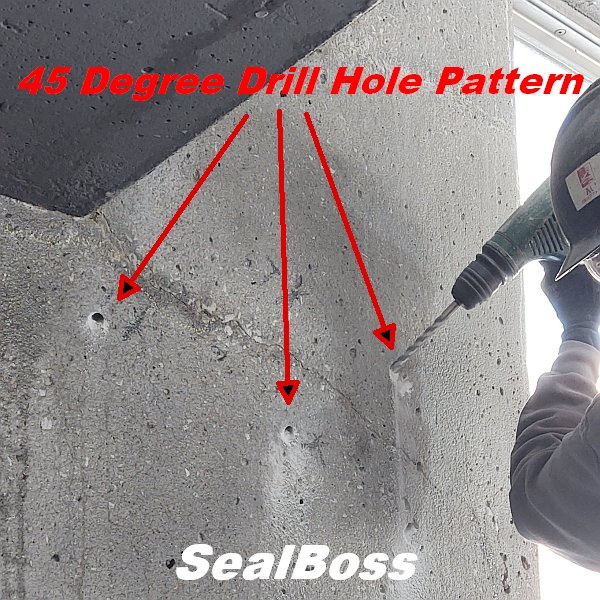

In those areas, SealBoss 1/2 inch injection packers were placed according to SealBoss Standard Recommendations, roughly 4” from the crack in ½” holes that were drilled at a 45-degree angle back into the crack. SealBoss 1510 Water Stop Foam was injected until positive refusal of the hydro-active resin was visible from the face of the crack as well as on the exterior side of the wall when a through crack was injected.

Starting with the lowest point of the cracks, SealBoss 1510 Leak Sealing Foam Grout was injected until positive refusal was observed on the interior and exterior of the wall. Due to the temperature of the wall, around 36 degrees Fahrenheit, the contractor was advised to condition the resin to room temperature prior to use as well as adding 15% of SealBoss 1510 Accelerator/Catalyst to compensate for the cooler ambient and substrate temperature — cold temperatures slow down the chemical reaction of the injection grout.

B – Custom Injection Procedure

In some areas, more complex leaking cracks and cold joints had to be sealed, requiring a deviation from standard injection packer placement.

Multiple cracks had developed connecting to a larger initial crack, creating a spider-web crack pattern. Due to the complexity of the crack system and intersections of cracks, the injection procedure was modified from the standard alternating “zipper” pattern typically recommended. Cracks were so close in proximity that packers needed to be strategically ‘custom’ placed to increase the chance for each packer drill hole to successfully intersect with the crack — resulting in a less orderly packer placement pattern.

Starting at the low point of crack, the Water Stop Foam was injected till and foam travel was observed at a distance from the point of injection intersecting into other cracks. This meant that multiple cracks could be addressed from one point of injection without the need for drilling too many injection port holes.

As the resin visibly moved up and out of the face of the crack, injection of that specific crack would be stopped so the resin could react and fully expand creating a seal.

Shortly thereafter, a secondary injection of the same packer was performed to penetrate even deeper into the crack and allow for further continuation of visible vertical foam resin travel.

Cleanup

After all cracks were successfully sealed, the injection packers were removed, and the ½-inch drill holes were patched with hydraulic cement for a clean finish. This step restored the surface integrity and appearance of the repaired areas.

Products Used:

Injection Resin:

- Injection Resin: SealBoss 1510 w/ 15x Accelerator – NSF/ANSI 61 Drinking Water Contact Certified PU Foam\

- Injection Packers: 1/2” 13-100 Evolution Aluminum Packers

- High Pressure Pump: P2002 Single Component Injection Pump

- Cleaning: R70 Pump Flush

Other Tools Used

Cleaning Materials: Xylene, rags, bucket

Additional Tools: 18” x 1/2″ drill bit — 3/8” Crescent Wrench — Dead Blow Hammer

Hammer Drill — Access 110v Power —

Vacuum

Heat Gun

Why Polyurethane Foam Injection?

Polyurethane foam injection is a versatile and effective solution for sealing leaking cracks in concrete structures.

Its advantages include:

- Hydro-Active Expansion: Reacts with water to create a watertight seal.

- Durability: Provides long-lasting protection against water intrusion.

- Flexibility: Can adapt to various crack patterns and sizes.

This method proved to be the ideal choice for the Gorilla Exhibit, ensuring a safer and more enjoyable environment for both animals and visitors.

Conclusion

The repairs at Omaha’s Henry Doorley Zoo highlight the effectiveness of polyurethane foam injection for sealing leaking cracks, even in complex and challenging environments. With proper preparation, high-quality materials, and expert execution, this method offers a reliable solution for protecting concrete structures from water damage.

Call Your SealBoss ® Technician

If you have any questions on crack injection water stop procedures or any injection related applications, please contact our team of qualified SealBoss representatives to schedule an on site consultation & full injection systems training. Call us at 714-662-4445.