Restoration Waterproofing

Restoration - Waterproofing

Restoration – Waterproofing with Injection Resins, Gels, and Foams

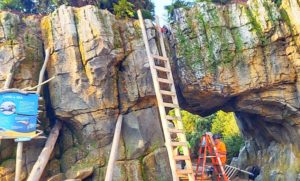

Restoration waterproofing projects represent a mix of various complex tasks, each with its unique set of challenges. The first crucial step is identifying the root source of the water infiltration, which at times can be a difficult process.

Diagnosis

A correct leak diagnosis might necessitate various steps, such as performing visual inspections of the inside and outside of the structure, examining the surrounding conditions, conducting flood tests, utilizing dye testing, creating mock-ups, and removing paints and finishes.

Setting Defined Objectives

Before starting a restoration waterproofing project, it is crucial to clarify the goals and expectations for every party involved.

It goes without saying that the primary aim of such a venture typically revolves around halting water intrusion. There are many techniques and products that can be used for this, such as polyurethane injection foams, gels, and resins, as well as acrylate injection gels and even epoxy resins in some circumstances. These methodologies come with their individual costs, levels of site disruption, and project timetables. It is essential that all of these elements are thoroughly considered and presented to the end customer, facilitating an informed decision-making process.

Understanding Water Movement and Migration

It is indispensable to understand some key concepts related to water migration and movement around and within soil, structures, voids, joints, and cracks.

Water is Not Always Visible

The obvious appearance of a leak in a specific location does not definitively imply that other areas are devoid of water ingress. Water invariably seeks the path of least resistance, typically navigating towards any openings, fissures, and low spots. Upon remediation of these lower areas, the water may find its way to other compromised zones.

Leak Detection Techniques

The leak detection process is further complicated if the repairs are undertaken during a period of relative dryness. Under such circumstances, leak migration might not become evident until the advent of the next rain event. For more controlled testing, it may be advisable to deliberately flood the surrounding area, creating conditions that could induce a leak at the time of inspection and repair. Conducting flood testing before, during, or after the repair work can contribute significantly towards pinpointing any areas where the leak may have migrated. Executing waterproofing repairs amidst active leaking can effectively help identify and repair leak migration issues.

Restoration Waterproofing Products

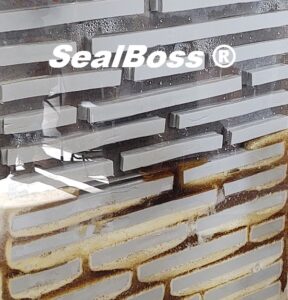

Polymer injection foams, resins and gels serve as viable solutions in restoration waterproofing. Their superior qualities make them ideal for sealing leaks, even in wet environments. Polyurethane foams are adept at sealing large leakages, both in volume and speed, expanding upon contact with water to block infiltrations effectively. On the other hand, super low viscosity resins and gels ensure a long-lasting solution for smaller, more intricate leaks, seeping into hairline cracks and curing to provide a waterproof seal. Implementing curtain injection behind a structure can effectively generate a waterproof, membrane-like barrier, thus sealing wet and damp spots within concrete and masonry structures.

At times, epoxy resins may be required to restore structural integrity, even in wet or damp conditions. For an in-depth comparison between epoxy and polyurethane injection, please refer to the detailed information provided here.

In Conclusion

Remedial restoration waterproofing is often an iterative, exploratory process that might necessitate adjustments along the way. Setting realistic expectations, keeping open lines of communication among all involved parties, and maintaining a keen eye for detail are important to the efficient and successful execution of a waterproofing process.

A well-executed waterproofing restoration can add years to the lifespan of a structure, safeguarding it against potential damage and preserving its aesthetic and functional value.

Restoration – Waterproofing Systems

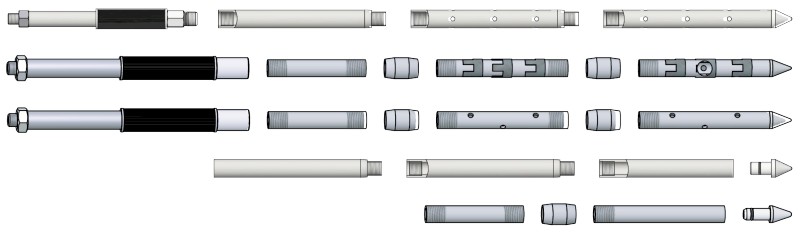

Popular Water Stop & Leak Sealing Injection Links

Leak Sealing Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam Grout

Our #1 Selling Polyurethane Injection Foam

Water Cut-Off Injection Grout

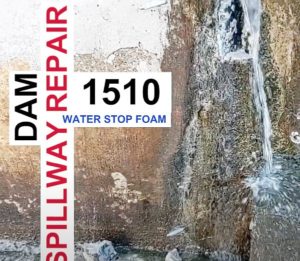

1510 PU Foam & Oakum Pipe Plug Kit

Leak Sealing Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam

Flexible Polyurethane Injection Foam

Flexible Foam, Water-Activated chemical grout.

Leak Sealing Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam

Super Low Viscosity Polyurethane Injection Foam,

Water-Activated chemical grout. Drinking Water

Accelerator for SealBoss Single Component Injection Foams

Accelerator For 1510/1570 PU Injection Foam. Adjust foam gel-time and foam expansion from low foaming to high foaming depending application.

Leak Sealing Injection Resin

Super Low Viscosity PUR Injection Resin

Two Component Flexible Resin

The solution for wet and dry surfaces and moving cracks. Extremely low viscosity for superior penetration in hairline crack injection.

Leak Sealing Injection Gel

Hydrophilic Injection Foam Gel

Hydrophilic Gel

Versatile Hydrophilic Polyurethane Foam-Gel

Water activated single component hydrophilic Polyurethane grout.

Leak Stop

Leak Sealing

Acrylate Gel

Acrylic Gel

Poly Acrylate Gel

Hydrophilic poly-acrylate gel / acryclic gel for soil stabilization, curtain-injection, infusion bladder injection into structures and to seal degrading masonry grout.