Sealing Tie Holes

Sealing Tie Holes

Sealing Tie Holes a.k.a. Tie-Rod Holes in Concrete Structures

Introduction

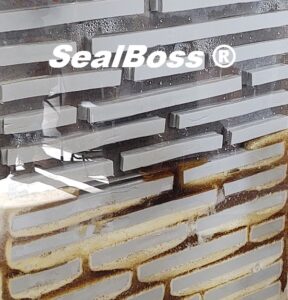

Tie holes, also called tie-rod holes, are small openings in concrete structures created after removing tie rods used in formwork. While essential during construction, these holes can become problematic, especially when exposed to hydrostatic pressure, leading to leaks. A proven and reliable solution to this challenge is polyurethane polymer foam injection.

In this article, we dive into a real-world example of a contractor effectively sealing tie holes and addressing shrinkage cracks in water tanks for a rural water district. By utilizing the advanced SealBoss Injection System, the team achieved lasting results, showcasing the importance of specialized training, the right equipment, and strategic application in preserving concrete structures.

This guide provides valuable insights into the problem of tie holes, effective sealing techniques, and the critical role of expertise in ensuring durable repairs.

What are Tie Holes in Concrete Structures and How to Seal Them Permanently

Tie holes are small openings left in concrete structures after the removal of tie rods, which play a critical role during construction. Tie rods are essential components of concrete formwork—the temporary mold used to shape poured concrete. These rods ensure proper alignment and stability of the formwork during the concrete pouring and curing processes.

Over time, tie holes can become a vulnerability in the structure, as they may begin to leak when exposed to hydrostatic pressure. This typically occurs when water from an external source presses against the opposite side of the concrete structure, leading to potential water infiltration.

Sealing Tie Holes with SealBoss Systems — Polyurethane Polymer Foam Injection is widely regarded as one of the most effective and long-lasting solutions.

This advanced sealing technique permanently stops leaks in tie holes, providing durable protection against water penetration. Its efficiency and reliability make it a top choice for maintaining the structural integrity of concrete constructions.

By understanding the importance of sealing tie holes and utilizing proven methods like polyurethane foam injection, you can prevent water damage and extend the life of your concrete structure.

Sealing Tie Holes and Cracks

A Case Study in Effective Water Tank Repair

Polyurethane Polymer Foam Injection is an effective method to seal leaking tie rods permanently

In the world of construction, particularly in the construction of water tanks, shrinkage cracks and tie-holes are common issues that can lead to slowly weeping or even significant leaks. These problems are often accompanied by visible efflorescence, signaling a need for immediate and effective repair.

A recent project by a contractor in a rural water district expansion north of Atlanta, Georgia, perfectly illustrates how these challenges can be met with the right expertise and equipment.

Encountering the Challenge

During the construction of water tanks in this project, the contractor encountered both shrinkage cracks and tie-holes showing signs of leakage.

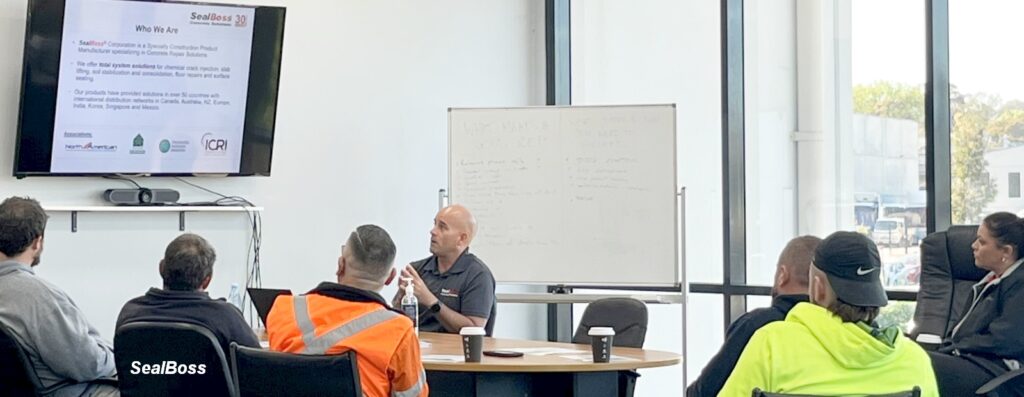

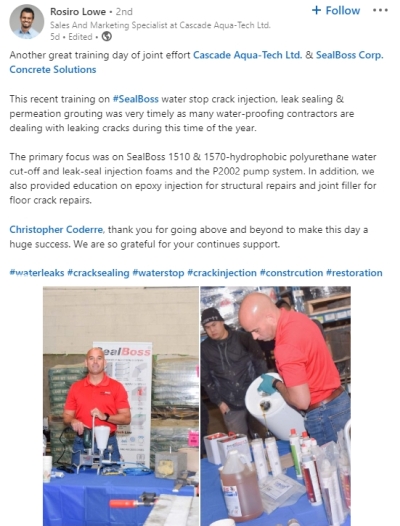

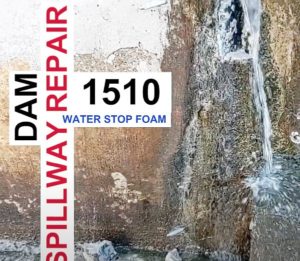

To address these issues effectively, the contractor sought on-site support and comprehensive systems training, specifically in the use of SealBoss 1510 NSF Hydrophobic Water Stop Foam and the P2002 High-Pressure Injection Pump.

The Training and Repair Process

The training began with a thorough inspection of the tank to identify the most actively leaking areas.

This was followed by a demonstration of the SealBoss Injection System application. The repair process involved a strategic approach to drilling holes:

The 1, 2, 3, 45 Degree Injection Method was used for the shrinkage cracks, and for sealing the tie-holes, a 45-degree hole was drilled 4 inches from the edge of each tie-hole until the steel insert was reached.

Preparation and Injection

Before the injection process, each drilled hole was pre-injected with water using a spray bottle. Given the ambient temperature of 38 degrees Fahrenheit, hot water (between 70 and 90 degrees Fahrenheit) was used for pre-injection to assist with the catalyzation time of the 1510 foam in the cold concrete. After flushing the holes, the installation of the SealBoss 13-100 AL Evolution Mechanical Packers commenced, followed by the injection process using the P2002 high-pressure injection pump.

Hands-On Learning and Independent Operation

The P2002 pump, known for its simplicity and drill-operated mechanism, was explained in detail. The training emphasized understanding injection pressure and the patience required for successful application.

Initially, the technician assisted with the pump operation, but within 10 minutes, the crew was able to inject independently.

Each packer was injected until there was positive refusal of material around each tie hole, and the same process was applied to the cracks.

Ensuring Long-Term Success

Once the crew gained confidence in operating the system, the focus shifted to cleaning and maintenance of the pump, ensuring its longevity and effectiveness for future projects.

Conclusion

This project north of Atlanta, Georgia serves as a prime example of how proper training and the right equipment can effectively address leaking tie holes and shrinkage cracks in new water tank construction.

The use of SealBoss 1510 NSF hydrophobic foam and the P2002 high-pressure injection pump, combined with hands-on training and a strategic approach to sealing, provided a durable solution to the problem of shrinkage cracks and tie-holes.

This case study not only highlights the importance of addressing these construction challenges promptly but also demonstrates the value of expert guidance and training in ensuring the longevity and integrity of water storage facilities.

Related Articles

Concrete Leak Sealing

Leak-Seal Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam Grout

Our #1 Selling Polyurethane Injection Foam

Water Cut-Off Injection Grout

Semi-Flex Foam, Water-Activated chemical injection grout. Our most versatile product. Water activated hydrophobic polyurethane foam, expands up to 30-40 times.

Accelerator for SealBoss Single Component Injection Foams

Accelerator For 1510/1570 PU Injection Foam. Adjust foam gel-time and foam expansion from low foamer to high foamer depending application.

- Light Weight, Modular Design

- Electric Drill Operated

- Single Piston System

- 6000+ psi – 1 Component

ALUMINUM MECHANICAL PACKER

Dimensions

1/2″ X 4″

13 x 100mm

Standard Packer

Economical packer with removable anti-return valve in zerk permits port-port travel technique by removing the zerk fitting. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Bestseller – a SealBoss Standard