SealBoss Slab Lifting Systems

Slab Lifting

Soil Compaction & Consolidation

Introduction:

Ensuring concrete structure stability often depends on addressing the underlying soil conditions. Techniques such as slab lifting, soil compaction, permeation, and consolidation injection systems provide the necessary support.

Using methods like polyurethane foam injection and permeation grouting, we can achieve efficient, non-invasive, and durable solutions for various soil and slab issues.

Effective void filling and slab lifting procedures can provide for stable subsoil to adequately support the structure above. If there are concerns about the subsoil’s stability, soil permeation grouting should be considered, provided the soil composition is suitable.

Slab Lifting and Void Filling

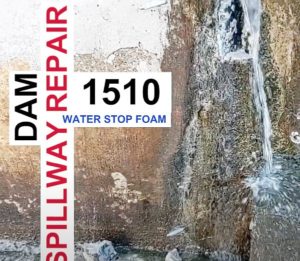

Slab lifting and void filling involve injecting structural polyurethane foam into voids beneath settling or uneven concrete slabs. This proven method stabilizes slabs without the need for excavation and adds minimal weight. Known as slab jacking, foam jacking, polyurethane concrete raising, poly jacking, or poly leveling, this technique offers several advantages over traditional mud jacking methods.

Advantages of Polyurethane Foam Injection

- Non-Invasive: No need for excavation, preserving the surrounding landscape and structures

- Lightweight: Adds minimal weight compared to other materials, reducing the risk of further sinking

- Quick Setting: Polyurethane foam sets rapidly, allowing for quicker project completion

- Durability: Provides long-lasting stability and support.

Permeation Grouting and Soil Stabilization

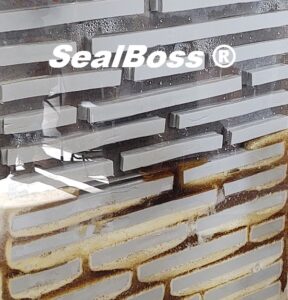

Permeation grouting and soil stabilization are performed by injecting a single-component, low-viscosity polyurethane hydro-active foam, catalyzed with an accelerator to specification, into the soil. This is done through injection packers, lances, or grout injection needles to consolidate and compact the substrate, increasing stability by binding soil particles together.

Procedure and Considerations

- Soil Analysis: Before any permeation grouting procedure, the soil composition must be analyzed to predict the effectiveness of the treatment

- Injection Process: The foam is injected into the soil to fill voids, stabilize loose soil, and enhance the load-bearing capacity of the ground

Equipment Used: Injection packers, lances, and grout injection needles are utilized to deliver the foam precisely where needed

Conclusion

Slab lifting, void filling, and permeation grouting are essential techniques for maintaining and restoring the stability of concrete structures. By using advanced polyurethane foam injections, these methods provide efficient, non-invasive, and durable solutions for various soil and slab issues. Proper soil analysis and the right application of these techniques ensure the long-term stability and safety of the structures.