Concrete Leveling Polyurethane Foam

Concrete Leveling Polyurethane Foam

Introduction to Concrete Leveling Polyurethane Foam

Concrete leveling polyurethane foam offers an innovative solution for maintaining the integrity of concrete slabs. This versatile material addresses various underlying issues that can cause slabs to become uneven or unstable.

Erosion

Erosion is a primary cause of concrete slab instability. It occurs when water washes away the soil beneath the slab. This can happen due to several factors:

- Improper Property Slope: Water directed towards the slab due to a slope can erode the soil

- Gutter Runoff: Inadequate drainage systems can cause water to seep into the soil

- Sewer Line Breakages: Wastewater from broken sewer lines can contribute to soil erosion

Substandard Soil Compaction

The foundation of a concrete slab depends heavily on the compaction of the underlying soil. Proper soil compaction reduces the space between soil particles, creating a solid base for the slab. If this process is skipped or done incorrectly, the slab is prone to sinking over time.

Expansive Soil

Expansive soils, which swell when they absorb water and shrink as they dry, pose a significant challenge to concrete slabs. This cycle of swelling and shrinking can cause the slab to lift, sink, and eventually crack, compromising its stability and appearance.

Tree Roots

Large trees near concrete slabs can also affect their stability. Tree roots can absorb water from the soil under the slab, causing the soil to shrink. Additionally, as these roots decay after the tree’s death, voids can form beneath the slab, leading to further instability.

Understanding the Causes

Understanding the factors that lead to concrete slab issues highlights the importance of using concrete leveling polyurethane foam. This solution not only addresses the root causes of slab instability but also provides a long-lasting fix, ensuring the durability and safety of concrete structures.

The Repair Process Overview

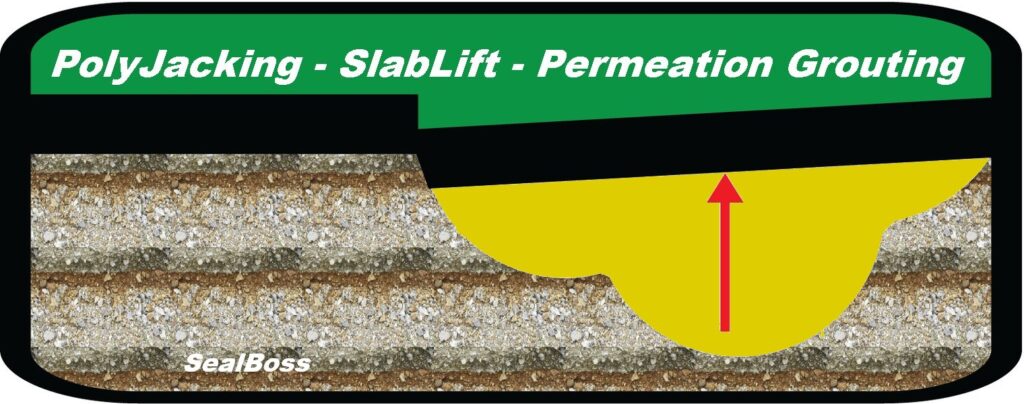

Concrete leveling foam, a two-component, high-strength polyurethane material, is pumped beneath sinking concrete slabs, sidewalks, driveways, or patios. It provides a strong foundation by filling the void and elevating the sunken concrete while expanding. The process is also known by various terms like polyjacking, concrete lifting, slab jacking, foam jacking, foam lifting, all achieving the same goal.

The Process in Detail

Leveling and Lifting: Utilizing the concrete slab itself to deliver polyurethane foam, our method raises the concrete, fills voids, and stabilizes soils. A small hole is drilled into the slab, into which a tapered delivery port is inserted. The injection gun, connected to the port, pumps the polyurethane material through the port and slab, with the foam expanding within seconds, compacting loose soil and lifting the concrete.

This highly accurate and simple process is executed via incremental injections. The lifting foam fully expands within a brief period, allowing for monitored elevation and prevention of over-raising the concrete slab.

Applications of Concrete Leveling Foam

Void Filling: Polyurethane foam is not limited to addressing concrete settling. It can also fill voids under slabs resulting from excessive settling or washouts. It imposes 15-25 times less weight than traditional mudjacking or cementitious grout mix, easing the pressure on a failed subgrade.

Joint/Slab Stabilization: Slab stabilization is critical when slabs lack support and are susceptible to cracking under heavy loads. This specialized foam, designed for joint/slab stabilization, fills voids to provide support and eliminate movement. Its slow reaction time and minimal expansion strength allow for thorough coverage under the slab or along a joint.

Concrete Leveling Polyurethane Foam Injection vs. Mudjacking

Concrete leveling foam offers several advantages over mudjacking, a method developed approximately one hundred years ago. Mudjacking is typicall messier and requires substantial machinery to transport and pump the heavy slurry under the slab. Any spillage can result in a significant mess. Mudjacking slurry, a mixture of sand, cement, and other natural materials, weighs approximately 100 pounds per cubic foot, compared to concrete leveling foam’s weight of 2.5 to 4 pounds per cubic foot. Moreover, the much larger 2-inch holes required for mudjacking can crack the concrete slab and provide an avenue for roots to penetrate.

Unlike mudjacking slurry, concrete leveling polyurethane foam is hydrophobic, inert, and waterproof, ensuring its structural integrity remains uncompromised when in contact with water. Conversely, mudjacking slurry can wash away upon contact with water, leading to further slab sinking.

Finally, concrete leveling foam operates with rapid effectiveness and exhibits prolonged durability. Upon being injected beneath the slab, it solidifies within mere minutes. On the other hand, mudjacking demands an extended application duration and frequently yields a shorter effective lifespan, which, dependent upon environmental factors and particular conditions, may only persist between 2 to 5 years before the slab descends again. This stands in sharp contrast to the notably extended typical longevity offered by concrete leveling foam.

Slab Lifting, Soil Compaction, Permeation, and Consolidation Injection Systems

Slab Lifting, Soil Compaction, Permeation, and Consolidation Injection Systems