Dam Spillway Leak Sealed

Dam Spillway Leak Sealed

SealBoss 1510 Polyurethane Foam

SealBoss 1510 Leak Sealing Application

What is the Purpose of a Spillway in Dams?

A spillway serves a critical function in dam systems. Either incorporated into the dam’s structure or built adjacent to it, a spillway facilitates the controlled and secure discharge of surplus water downstream.

Introduction

Spillways play a critical role in safely managing excess water in dam systems. Over time, leaks can develop in cold joints and cracks, posing structural risks and operational challenges. Traditional repair methods often fall short—especially under high water pressure.

SealBoss 1510 Water Stop Foam offers a reliable solution. Its hydro-active, expanding polyurethane formula penetrates deep into leaking areas, sealing active water flow and forming a durable, watertight barrier. This article highlights a successful spillway leak repair using Water Stop Foam, demonstrating its effectiveness where other methods failed.

SB 1510 Polyurethane Foam in Dam and Spillway Leak Sealing

Dam Spillway Leak Sealed with Advanced Polyurethane Foam Injection

When it comes to critical infrastructure, few challenges are more pressing than water intrusion in dams. One of the most effective solutions available today is SealBoss 1510 Water Stop Foam, a high-performance, hydro-active polyurethane product. This case study and technical overview demonstrate how a dam spillway leak was sealed using SB 1510 polyurethane foam, offering a lasting and economical solution.

Why Polyurethane Foam for Dam and Spillway Leak Repairs?

Polyurethane foam is widely respected for its low viscosity and superior adhesive properties, making it ideal for sealing active water leaks in dam and spillway structures. Its hydro-reactive nature enables it to expand on contact with water, effectively filling cracks, joints, and voids — even under high-pressure flow.

When injected into a leaking dam or spillway, the foam penetrates deeply into fissures and gaps. It reacts quickly with water, expands, and cures into a solid, waterproof barrier. This process forms a robust seal that prevents further water ingress and strengthens the surrounding substrate.

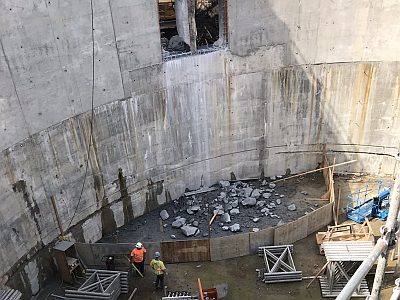

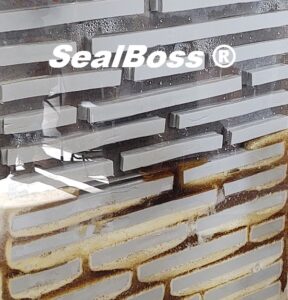

How Dam Spillway Leaks Are Sealed Using SealBoss 1510

The leak remediation process begins with drilling holes along the affected cold joints or cracks in the dam spillway. Mechanical injection packers are then installed, allowing SealBoss 1510 to be injected precisely where needed. The foam expands rapidly within the concrete structure, bonding to the substrate and stopping the leak at its source.

After curing, the foam forms a permanent repair that is resilient, flexible, and capable of withstanding ongoing hydrostatic pressure—making it one of the best solutions when a dam spillway leak must be sealed quickly and reliably.

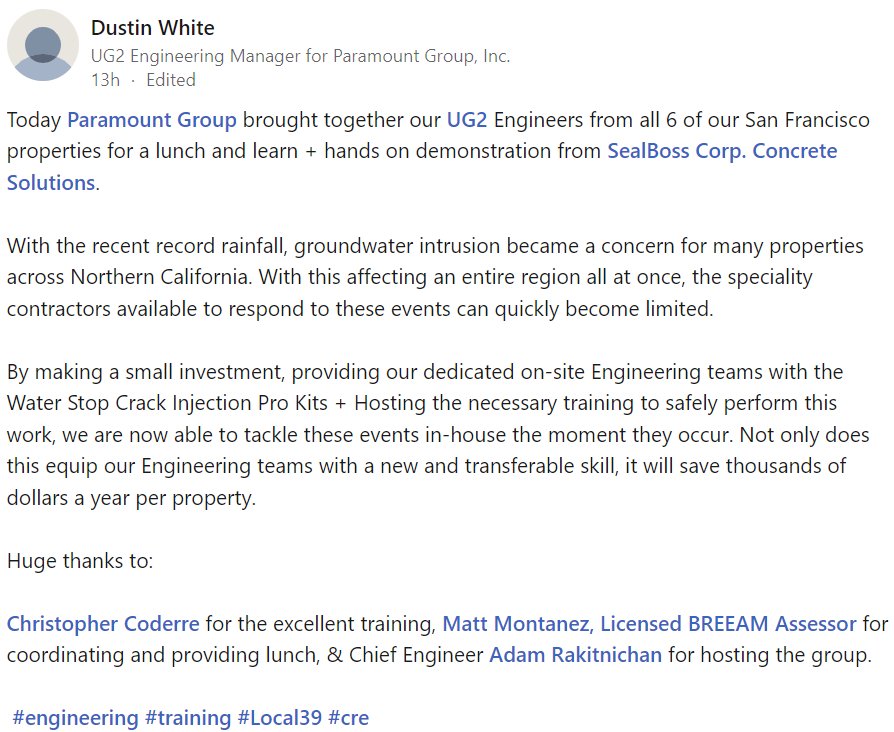

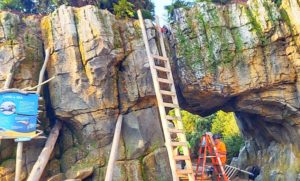

Case Study: Dam Spillway Leak Sealed After Multiple Failed Repairs

Background: Persistent Cold Joint Leak

SealBoss was contracted to repair a leaking cold joint in a dam spillway—one that had already failed four previous repair attempts. Prior caulking had eroded due to continuous water pressure, allowing active leakage through the “V” notched joint. With increasing water infiltration, the situation called for a proven, robust method to get the dam spillway leak sealed once and for all.

Step-by-Step: Leak Sealing with SB 1510 Water Stop Foam

- Surface Prep and Joint Access

Technicians began by removing loose and deteriorated caulking to fully expose the leaking joint. Drill holes were made adjacent to the joint, and active water flow confirmed correct placement. - Oakum Soakum Technique

To immediately address the gushing leak, the team applied the Oakum Soakum method using SealBoss 1500 Seal Oakum saturated with SealBoss 1510 and accelerated with 15x Accelerator for fast reaction and curing. The oakum was placed directly into leaking crevices to form an initial water block. - Injection Packer Installation

Next, 13-100 AL mechanical packers were installed in a staggered vertical pattern, based on SealBoss’s 1 – 2 – 3, 45 – Degree Injection Guidelines. Strategic spacing ensured coverage while avoiding rebar interference. - Polyurethane Injection

Using the SealBoss P2002 injection pump, catalyzed SB 1510 foam was injected starting from the lowest packer. Controlled pauses allowed the resin to expand fully, minimizing waste while maximizing penetration.

Result: Dam Spillway Leak Sealed with Lasting Effect

All leaking joints were successfully sealed. The high-pressure, active leaks were stopped effectively, and the structure’s integrity was restored. This application proved once again that SealBoss 1510 polyurethane foam is a powerful tool in dam and spillway leak sealing.

Conclusion

If you’re facing persistent water intrusion, cracks, or joint failures in spillway structures, getting the dam spillway leak sealed properly is critical.

The SealBoss 1510 Water Stop Foam injection system provides a fast, durable, and cost-effective repair method—even under high-flow conditions.

This proven technology not only stops active leaks but also extends the life of dam infrastructure. As this case study demonstrates, polyurethane grout injection is the gold standard for dam and spillway maintenance.

Ready to get your dam spillway leak sealed?

Contact SealBoss today at 714-662-4445 or visit our website to connect with an expert and find the right solution for your project.