Versatile Injection Grout SealBoss 1510

SealBoss 1510 Features Summarized in a 5 Minute Overview

Podcast Transcript

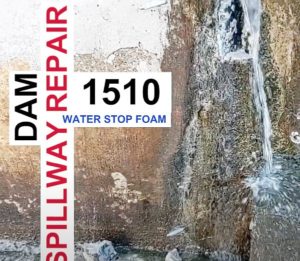

Okay, let’s unpack this. You know, imagine maybe a historic building standing firm despite relentless groundwater. Or maybe a subway tunnel where not a single drop seeps through. Ever wondered how critical challenges like persistent water leaks in concrete or maybe unstable soil beneath massive structures are actually tackled? Today, we’re taking a deep dive into a powerful, often unseen solution that really gets into the structure of our world. Our mission then is to explore what’s widely considered the most versatile injection grout out there: SealBoss 1510. You might also know it as Water Stop Foam.

Yeah, that’s right. And it’s not just any product. It’s a flagship for a reason. It’s specifically engineered for professional use across a really surprising and vital range of applications. It’s one of those silent heroes, really.

Okay, so let’s get into the nitty-gritty then. What is this water foam? Is it like the spray foam insulation you might use in your attic, or something else entirely?

That’s a great question. They’re both foams, yes, but very different chemistry and purpose. SealBoss 1510 is actually a specialized liquid sealant first. We call it hydrophobic, which basically just means it repels water—it actively pushes it away. And critically, it’s water-activated. The moment it hits water—bang!—it kicks off a chemical reaction, okay?

It expands, forming this dense, impermeable foam. It’s based on MDI polyurethane. That’s a really robust polymer, very durable. Plus, it’s formulated to be 100% solvent-free and 100% solids. Very pure, very potent stuff. And when you mix it with its 15X accelerator additive—well, that one is really designed to cut off flowing water almost instantly.

Yeah. Hold on, 40 times expansion? Did I hear that right? That sounds huge.

You did—40 times. It’s pretty astounding.

So, you could fill up massive voids with just a tiny amount of product. That seems incredibly efficient.

Exactly. That huge expansion factor isn’t just for show. It’s a total game-changer for efficiency on-site. It means you can tackle really big voids and high-volume leaks with surprisingly little material. It makes jobs faster, more effective, and ultimately saves costs.

Makes sense.

And beyond that, here’s where its credentials really make a difference. It’s NSF/ANSI 61 certified for drinking water contact.

Okay, that sounds important. NSF/ANSI 61. What does that actually mean in practice for where it can be used?

Oh, it’s absolutely vital. That certification means it’s proven safe to use in critical drinking water infrastructure. Think reservoirs, water treatment plants, the pipes carrying water to your tap, right?

It guarantees no harmful stuff leaches into the water supply. That’s a huge differentiator, something generic products just can’t claim.

Oh, I see.

And just on a practical note, it’s even unregulated for transport, which might sound minor, but it really simplifies getting it to job sites, especially tricky ones.

That’s a lot packed into one product for stopping leaks.

Yeah.

So, thinking about concrete leaks specifically, what kind of cracks are we talking about? Does it work for absolutely everything?

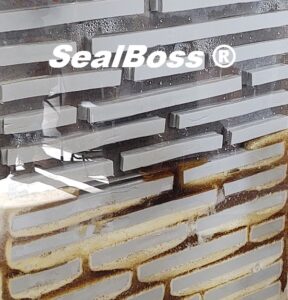

Well, for most crack injection scenarios in concrete, this foam is definitely the go-to. It’s incredibly versatile. It handles everything from tiny hairline cracks you can barely see all the way up to gaps about 3/4 of an inch wide.

Okay, 3/4 inch. So, what if it’s wider than that? A really big gap?

Yeah. For those wider, more challenging ones, there’s the oakum method, sometimes called the oakum rope method. It involves soaking a special fibrous rope, oakum, in the 1510 liquid and then packing that soaked rope into the larger crack.

The foam then expands in and around the oakum, creating this really robust composite seal. Very strong, very long-lasting.

Right. Got it. You mentioned versatility earlier, and I’m really struck by how far its uses go beyond just filling cracks. What else can this stuff do?

Oh yeah, its applications really do extend significantly beyond just simple crack repair. If you look at the bigger picture, yes—general leak sealing, concrete repair—but also vital void filling. That’s a big one. For instance, injecting it underneath concrete slabs. Imagine a sinking driveway or maybe a warehouse floor that needs lifting or stabilizing. That’s often called blanket injection.

The foam spreads out horizontally like a blanket, creating a solid support layer underneath.

Okay, blanket injection.

Or say you have water constantly seeping through a basement wall; you can inject the 1510 behind the wall itself. It creates this impermeable curtain or bladder of foam back there. Stops the water before it even gets to the concrete. That’s curtain injection.

Curtain injection. Wow. And I definitely saw something about soil stabilization, too. That sounds like a completely different field of engineering almost.

It really is. And it just shows the material’s adaptability. If you use just a low percentage of that 15X accelerator, the reaction changes. The material’s properties shift, and it becomes this highly effective soil stabilization grout.

How does that work?

It basically permeates into loose soil or pockets of gravel deep underground. Then it expands and hardens, binding everything together. Turns unstable ground into a solid, cohesive mass.

Incredible.

Which makes it super valuable for really challenging geotechnical projects. Things like supporting deep excavations, keeping tunnels stable while boring, strengthening the ground. It prevents collapses, keeps things safe. It truly shows the breadth of it, you know, from sealing a tiny leak to basically fortifying sections of the earth.

So, what does this all mean for you listening in? Well, next time you walk past a construction site, see a newly stabilized building foundation, or maybe just notice your own basement is miraculously dry after a downpour, you’ll know there could be a highly specialized material, something like SealBoss 1510, working unseen, solving these complex problems that quietly keep our world structurally sound and running smoothly.

Absolutely. It just highlights how these specific advancements in material science really underpin the safety, stability, and longevity of everything we build—often without us even realizing the complex solutions involved. So maybe think about this: what stands out to you about the unseen materials, the hidden technologies that make our everyday environment work?

Originally from Baltimore Maryland, Ben Ball has been working in the concrete repair industry for over a decade. He has worked on the repair, waterproofing and strengthening of structures ranging from high-rise condominiums to underground concrete vaults.

Originally from Baltimore Maryland, Ben Ball has been working in the concrete repair industry for over a decade. He has worked on the repair, waterproofing and strengthening of structures ranging from high-rise condominiums to underground concrete vaults.