Floor Joint Filler Pumps

Crafted from 30+ Years of Experience and Trusted Customer Insights

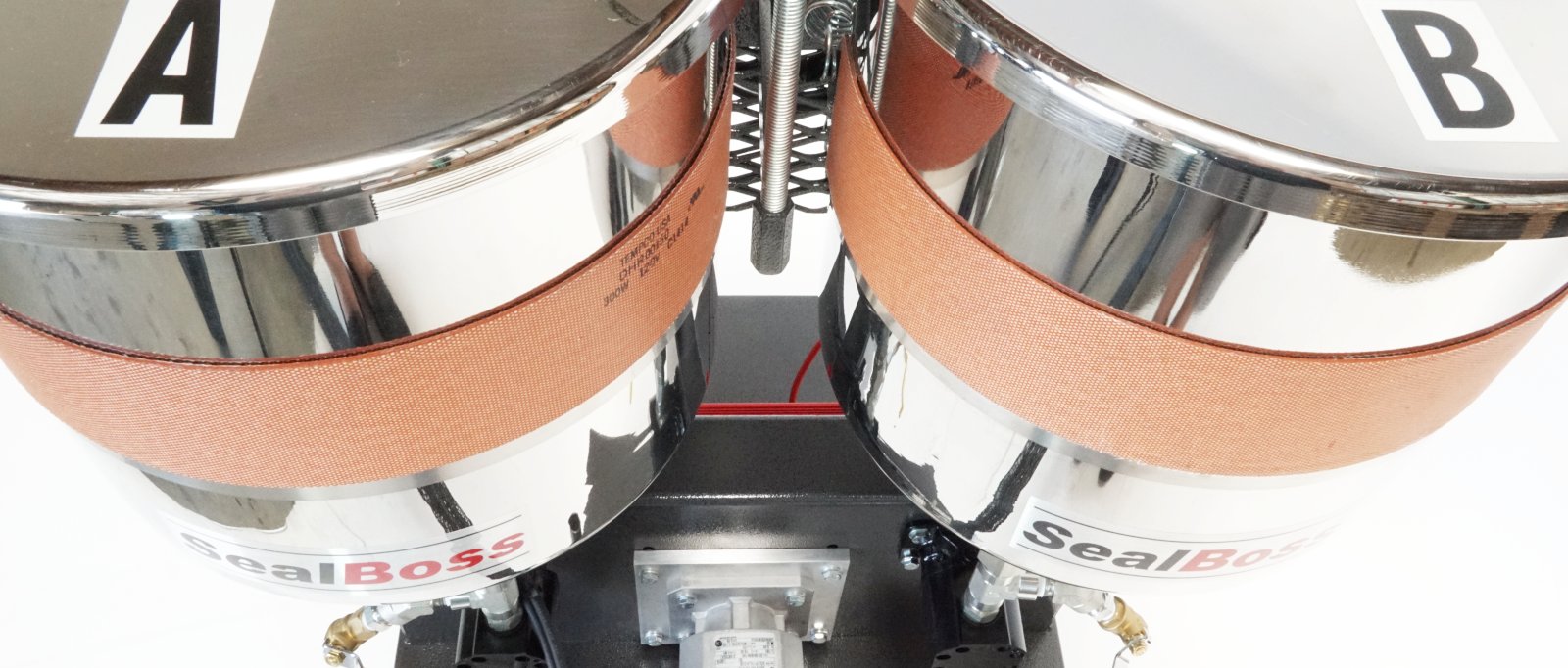

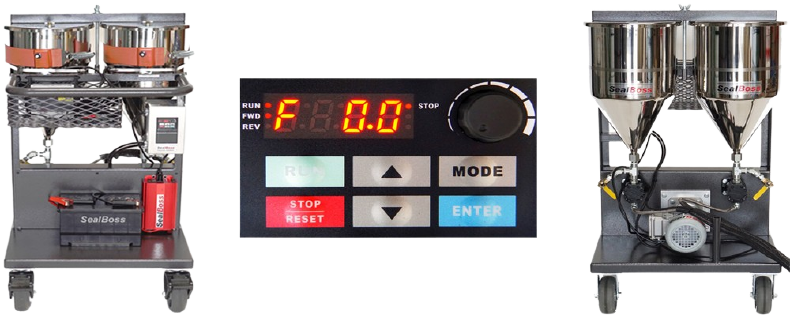

SealBoss® JointMaster® Pro2 G3i

The industry standard for fast, even floor joint filling — two-component, digitally controlled, stainless-steel build.

- Even, controlled flow for uniform joints

- Digital speed control with on-the-fly adjustment

- 6-gal stainless-steel tanks, heavy-duty frame

- Pumps polyurea, polyurethane, and epoxy joint fillers

- Adjustable output ~0.1 to >1.0 GPM (material-dependent)

Where it excels

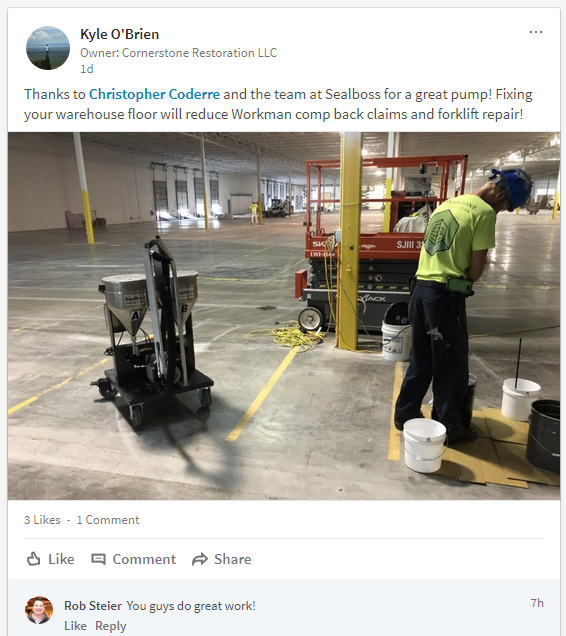

- Warehouses & distribution centers

- Manufacturing & industrial floors

- Retail big-box and back-of-house

- Airports and transportation hubs

- Cold storage (material-compatible)

Are You in the Market for a New Floor Joint Repair Pump?

Floor joint repair pumps go by many names; Floor Joint Pump, Polyurea Joint Fill Pump, Floor Epoxy Pump, Polyurethane Floor Joint Filling Pump, etc.

Even though companies market these machines with similar vernacular, it is important to know these machines are not all the same. It is important to know exactly what material your pump is designed for in order to get the best results and not damage your machine.

Before you purchase a machine for your intended application, it always important to factor in the different attributes of your pump, before you make your final decision.

Key Factors to Consider Before Your Purchase

Function: Can it reliably pump the materials you need?

- Always refer to data sheets and SDS.

- Consult a technician for precise advice.

Design: Appearance matters.

- A professional, sleek design boosts confidence.

- Ensure there aren’t any nuts, bolts, or awkward seams protruding.

Quality: Daily use can take a toll.

- Opt for machines with robust frames and superior workmanship.

- High-pressure gear pumps are a must to prevent costly leaks.

- Only settle for top-quality, CE-rated motors.

Versatility: Does it cater to your unique needs?

- Look for options like extended battery operation, heater bands for cold environments, and additional purge valves.

Safety: Never compromise.

- Ensure all moving parts are fully enclosed.

- Avoid machines where the full voltage runs through the applicator wand.

Price: Seek value, not just cost.

- A system’s longevity and ease of maintenance are paramount.

Introducing: The Sealboss JointMaster Pro 2

Consider the industry gold-standard, the JointMaster stands out as a third-generation professional machine.

- Built on valuable customer feedback and real-world experience.

- Boasts an innovative low-voltage control line, ensuring no high voltage at the applicator wand – a unique Pro2 standard.

- Trusted and sold worldwide.

- The SealBoss JointMaster Pro 2

Partner with SealBoss

Let us elevate your business with superior products and expertise. Maximize your investments with our high-quality range and exceptional know-how.

Questions? Need a Quote?

Connect with us at 714-662-4445. We’re here to help.

Links to JointMaster Floor Repair and Joint Filling Applications