Cold Joint Injection

Cold Joint Injection

Leaking Cold Joints Sealed

Cold Joints in Concrete Structures and the Polyurethane Polymer Solution

Introduction

Concrete is a versatile and strong material that plays a key role in modern construction, but it comes with certain challenges. One common issue is the formation of cold joints — visible lines or separations that occur when new concrete is poured against concrete that has already begun to set. These joints can compromise the structural integrity, creating weak points that are vulnerable to water infiltration, leaks, and long-term damage. Proper identification and repair of cold joints are essential for maintaining the durability and performance of any concrete structure.

Cold Joint Injection: Permanent Solutions for Concrete Leaks and Structural Integrity

Concrete is one of the most widely used building materials in the world due to its strength, versatility, and durability. However, like all materials, concrete has vulnerabilities. One of the most common and potentially damaging issues in concrete construction is the formation of cold joints. These unplanned discontinuities in concrete can significantly impact the long-term integrity of structures, particularly when they become pathways for water infiltration.

Fortunately, cold joint injection using advanced polyurethane polymers offers an effective and lasting solution. This article will explore what cold joints are, why they occur, the risks they pose, and how cold joint injection provides a reliable fix for both residential and commercial construction projects.

What are Cold Joints?

A cold joint forms when freshly poured concrete is placed next to or on top of concrete that has already started to set. Rather than bonding as one cohesive mass, the two layers remain separated by a visible and structural boundary. This boundary lacks proper adhesion and can act as a weak point in the structure.

Cold joints typically occur due to:

Delays in pouring concrete batches

Interruptions in concrete delivery or placement

Temperature variations that cause uneven curing

Scheduling issues or construction mistakes

The result is a distinct line or seam in the concrete that appears harmless at first but can lead to serious problems over time. Cold joints are particularly vulnerable to water infiltration, which can trigger internal corrosion of rebar, cause freeze-thaw damage, and reduce the overall life expectancy of the structure.

Cold Joint Injection: The Polyurethane Polymer Foam Solution

The most effective way to repair and seal cold joints is through a process called cold joint injection, using high-performance polyurethane injection resins. This method restores the integrity of the concrete joint and creates a watertight barrier that prevents future leaks.

Why Use Polyurethane for Cold Joint Injection?

Polyurethane injection resins are hydrophobic or hydrophilic foams that expand upon contact with moisture, filling voids and cracks with precision. When injected into a cold joint, the resin reacts with any water present, forming a flexible yet durable foam that bonds tightly to the surrounding concrete.

Benefits of polyurethane cold joint injection include:

Expands to fill cracks and voids – Ensures complete coverage and sealing

Forms a watertight barrier – Prevents water infiltration and leak recurrence

Flexible and durable – Adapts to slight movements and temperature changes

Non-invasive – No need for major demolition or reconstruction

Fast-curing – Rapid installation and reduced downtime

Step-by-Step Cold Joint Injection Process

The cold joint injection procedure typically involves the following steps:

Inspection and Assessment

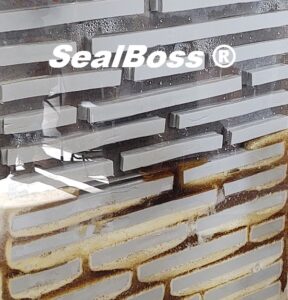

The area is assessed to determine the severity of leaks, substrate condition, and appropriate injection points.Drilling and Packer Installation

Holes are drilled at specific intervals along the cold joint. Mechanical injection packers are inserted to allow precise resin delivery under pressure.Injection of Polyurethane Resin

Using a high-pressure injection pump, the polyurethane resin is injected into the packers. As it travels into the joint, the resin reacts with moisture, expanding and filling all voids and cracks.Sealing and Curing

Once the injection is complete, the resin cures quickly, forming a flexible, watertight seal. Packers are then removed and holes patched.Final Inspection

The site is checked to ensure the leak has been completely sealed and no further moisture intrusion occurs.

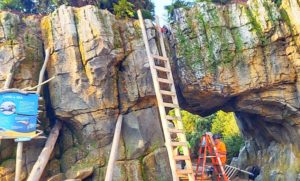

Real-World Application: SealBoss Cold Joint Injection in Kansas City

A recent project in Kansas City demonstrated the effectiveness of SealBoss’s cold joint injection system. A structure with both vertical and horizontal cold joints had developed active leaks due to a failed pre-existing waterproofing system.

SealBoss’s Regional Sales Manager provided on-site support and training during the injection process. The contractor drilled injection holes and installed ½” mechanical packers for a secure fit. Based on site conditions, both angled and direct drill placements were used.

The team injected SealBoss 1510 polyurethane resin using the P2002 high-pressure single-component injection pump. Due to the low substrate temperatures, the resin was catalyzed with 15% SealBoss 15X High Foaming Accelerator, which ensured rapid and effective expansion. The result? All active leaks were sealed successfully, and the structure’s cold joints were permanently reinforced.

Advantages of SealBoss Cold Joint Injection Systems

SealBoss offers industry-leading cold joint injection materials and equipment designed for professional contractors and infrastructure repair specialists. Key advantages include:

Complete waterproofing solutions for cold joints, cracks, and voids

High-performance resins that expand even in low temperatures

Specialized pumps and packers for efficient delivery

On-site technical support and training

Trusted by contractors worldwide in demanding applications

Whether repairing parking garages, basements, retaining walls, or tunnels, SealBoss systems deliver reliable, long-term protection against water intrusion and structural decay.

Cold Joint Injection: An Investment in Longevity

Repairing cold joints with polyurethane injection is not just a short-term fix—it is a long-term investment in structural performance. By addressing water infiltration early and effectively, property owners and contractors can prevent costly repairs, ensure code compliance, and extend the service life of critical structures.

For engineers, architects, and maintenance professionals, understanding the value of cold joint injection is key to preserving the quality of concrete infrastructure.

Contact SealBoss for Expert Cold Joint Solutions

SealBoss is a global leader in leak sealing, structural repair, and concrete protection technologies. If your project involves water leaks, cracks, or cold joints, contact our team for expert guidance, high-performance products, and technical support tailored to your needs.

SealBoss delivers on-site training and specialized technical assistance for tackling cold joint leaks, as well as other concrete structure issues.

Considering a Solution for Sealing Cold Joints During Construction?

Look no further! We not only offer systems specifically designed for sealing cold joints but also provide expert advice to prevent moisture issues right from the construction stage.

Materials and Tools Used

- SealBoss 1510 Leak Sealing Foam

- SealBoss 15X Accelerator

- SealBoss 13-100 Evolution Packers

- SealBoss R70 Pump Cleaner

- SealBoss P2002 Injection Machine

Related Articles

- Water Treatment Plant – Crack Leak Sealing Repair – NSF/ANSI 61 Certified Foam Injection

- Water Treatment Plant Repair

Learn More

Please don’t hesitate to call us at 714-662-4445 with any questions, or request to be contacted here, we look forward to helping you find a solution. On-site support from knowledgeable and experienced technical reps is available upon request.