Stainless Steel Grouting Needles

Stainless Steel Grouting Needles

How to Use & Select Injection Needles

Grout Injection Needles are used for specialty grouting applications, such as product delivery into soil substrates, injection through small holes and gaps, as well as injection with the Oakum Soakum Injection Technique. Suitable for polyurethane, polyacrylate, and silicate chemical grouts.

Deliver the Chemical Grout with precision to where it is needed

- Soil Injection

Stabilize and consolidate loose dirt with polyurethane grout. Penetrate the soil with your injection needle to the desired depth. Start the pressure injection process and slowly pull your injection needle back. Repeat as needed.In the video below we demonstrate how to install stainless steel injection needles in the soil in preparation for the soil permeation, consolidation, and waterproofing polymer grout injection.

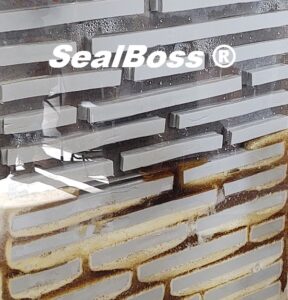

- Oakum Soakum Injection

Step 1: Perform the ‘Oakum Soakum Technique’ to seal wide joints, gaps and gushing leaks.

Step 2: Use the injection needle of desired length and push the needle through the cured oakum|grout barrier to inject SealBoss polyurethane water stop grout behind the temporary seal to create a permanent grout seal. - Conduit Injection

Use the stainless steel grout needle of desired length to transport leak-sealing foam deep into the conduit. Slowly retrieve needle under injection and create a dense seal inside the conduit.

Our Stainless Steel Grouting Injection Needles are professional grade and must be handled with care

Injection needles are designed to penetrate deep into soil with the least effort possible. They have a sharp angled oval needle point to puncture through oakum seals. Always handle and transport needles with extra care!

As we demonstrate in the video, injection needles are very sturdy and versatile. They are designed to transport your injection grout through barriers such as dirt, sand, oakum and other types of soft joint seals.

Please always handle your injection needle with extra care. The stainless steel is very strong and the tips are very sharp. They are manufactured to meet professional standards and to maximize your positive injection experience.

Please don't hesitate to contact us here at Sealboss for more information about our extensive injection equipment and accessory selection. Your representative will be happy to assist.

We provide on-site support and training for all SealBoss System Solutions.