Midwest Joint Fill Training | SealBoss 6500 Polyurea & JointMaster Pump

Midwest Joint Fill Training

SealBoss 6500 Polyurea & JointMaster Pump

Another

On the Job Training

Joint Fill & Repair

Heartland Warehouse Renovation

Introduction:

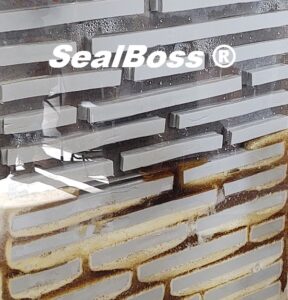

This article explores the real-world training and application of the SealBoss® 6500 QuickFix Polyurea Joint Filler and the JointMaster® Pro2 Pump during a recent aerospace facility renovation project. The focus is on the critical importance of proper industrial floor joint repair in high-performance environments, particularly in sectors with heavy equipment use and stringent facility requirements.

The case study is based in St. Louis, Missouri, where a local contractor—new to joint filling work—was selected to complete repairs on 6,000 linear feet of floor joints. Understanding the complexity and performance standards expected by the aerospace client, the contractor partnered with SealBoss for professional training. A SealBoss Technical Representative provided on-site, hands-on instruction to ensure proper use of both the material and the pump system.

This project showcases the effectiveness of direct technical support and the role of quality equipment in enabling successful outcomes, even for contractors without prior experience in joint filling. It also highlights how tailored renovation work helps prepare industrial floors for the heavy-duty usage expected in aerospace and manufacturing environments.

As the construction of tilt-up concrete buildings and warehouse facilities continues to rise nationwide, many existing structures are not immediately suitable for new tenants and require modification before operations can begin. Floor joint restoration using reliable products like SealBoss 6500 Polyurea and the JointMaster Pro2 Pump can be an essential part of that process—ensuring durability, performance, and long-term facility integrity.

SealBoss Expertise Elevates Industrial Floor Joint Repair at Aerospace Facility

On-Site Training Brings Professional Results in St. Louis, Missouri

In the thriving industrial hub of St. Louis, Missouri, SealBoss was called upon to provide specialized, on-site training in the use of SealBoss professional-grade Floor Repair Systems.

A SealBoss Technical Representative visited a local contracting team to deliver targeted instruction in joint filling techniques using the SealBoss® 6500 QuickFix Polyurea Joint Filler and the JointMaster® Pro2 Dispensing Pump.

This hands-on training session was designed not only to introduce the contractor to SealBoss technologies but also to prepare them for an urgent renovation at a warehouse soon to be occupied by a major aerospace company. The goal: enable a successful, high-performance floor joint fill that would meet the strict operational standards of a high-profile tenant.

Meeting Aerospace Industry Demands with Advanced Joint Filler Technology

The aerospace industry places exceptional demands on facility infrastructure. In this case, the client required a durable floor surface capable of handling continuous heavy forklift traffic and the movement of substantial aerospace components.

To meet these challenges, the project team selected SealBoss 6500 QuickFix Polyurea, a fast-cure, heavy-duty joint filler with A 80 Shore hardness and 200% elongation. This advanced material is engineered for industrial environments where impact, stress, and movement are constant. Its flexibility and toughness ensure long-lasting performance—especially crucial in environments that cannot afford downtime.

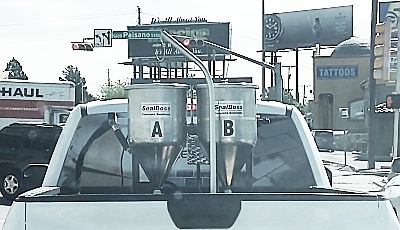

Equipping the Team: The JointMaster® Pro2 Joint Fill Pump

The project marked the first time the contractor used the JointMaster® Pro2 Pump, a battery-powered, dual-component pump designed specifically for dispensing fast-setting polyurea joint fillers. Recognizing the importance of proper equipment use, the SealBoss Technical Representative provided detailed instruction on pump operation, material mixing, flow control, and cleaning procedures.

Thanks to its intuitive design, the pump quickly became a natural extension of the crew’s workflow, allowing for precise, efficient filling throughout the day.

Scope of Work: 6,000 Linear Feet in One Day

The scope of the project was significant: fill and finish 6,000 linear feet of floor joints within a single day. While ambitious, this target was achievable through careful planning, expert training, and the efficiency of the SealBoss system.

Day-Before Surface Preparation

Preparation began the day before joint filling, with the contractor removing all failed or deteriorating joint material. Adhesion and delamination issues were resolved, and the joints were cleaned thoroughly. Backer rod was inserted to the proper depth across all areas to ensure optimal material flow and control during the next day’s application.

Streamlined Team Configuration for Maximum Efficiency

To complete the project in the shortest possible time while ensuring seamless execution and maximum efficiency, a three-man crew configuration was implemented:

Pump Operator – Managed flow and refill, maintaining steady output from the JointMaster Pro2 Pump.

Joint Filler Applicator – Guided the dispensing nozzle and ensured joints were filled evenly.

Floater / Finisher – Performed critical joint shaving within 8–15 minutes of fill, maintained supply of materials, and ensured the entire process stayed on track.

This streamlined crew layout proved highly efficient for fast-paced, high-volume joint filling.

From Training to Performance: Results That Speak for Themselves

After a concise yet thorough training that included a product overview, equipment setup, and a 20-minute hands-on session, the contractor’s team quickly demonstrated their ability to handle the task. With a dispensing rate exceeding half a gallon per minute, the crew successfully filled and shaved the entire 6,000 feet of joints in a single day.

This successful outcome underscores the transformative value of SealBoss support—empowering even less-experienced contractors to deliver professional results under demanding conditions.

Conclusion: High-Caliber Products Paired with Expert Support

This project in St. Louis exemplifies the SealBoss commitment to excellence—combining premium products with in-person technical training to deliver top-tier industrial solutions. As the demand for tilt-up warehouse renovations grows across the United States, projects like this one illustrate the value of selecting a partner who goes beyond product sales and invests in contractor success.

With SealBoss 6500 QuickFix Polyurea Joint Filler and the JointMaster Pro2 Pump, facilities can be prepared to meet the rigorous demands of aerospace, logistics, and other heavy-duty industries—quickly, efficiently, and professionally.

Interested in training, product demos, or partnership opportunities? Contact SealBoss today.

“We Provide Field Service When You Need It!

We have been offering experienced and responsive technical support since 1988. While providing on-site support and training, we create a positive learning environment focusing on building applicator confidence allowing for successful repairs to be continued after the training. From training new companies and their employees, SealBoss has continued to provide support to our clients for over 36 years.

On-site training consists of an overview of products, the pump and it’s features. This is followed by hands on training with actual dispensing of material on the job site until the applicator has gotten confident with the application techniques and nuances of the material used. Finally we focus on the correct cleaning procedure of the equipment.

We don’t leave a job site until I’m confident that everyone is fully comfortable with the systems and capable of teaching the next person in line.

With a knowledgeable technical support team, we are here to help with any questions you may have.”