Bridge Crack Repair

Bridge Crack Repair

Structural Epoxy Injection with Professional Equipment

Structural Epoxy Injection & Equipment for Bridge Crack Repair

Bridges, crucial for transport and commerce, often face damage from harsh environments and heavy traffic, leading to cracks and structural issues.

A cost-effective solution is crucial for maintaining bridge safety, and structural epoxy injection has become a popular method to repair cracks and restore integrity without expensive replacements.

Structural Epoxy Injection & Equipment for Bridge Crack Repair

Bridges, crucial for transport and commerce, often face damage from harsh environments and heavy traffic, leading to cracks and structural issues.

A cost-effective solution is crucial for maintaining bridge safety, and structural epoxy injection has become a popular method to repair cracks and restore integrity without expensive replacements.

Bridge Crack Repair:

Enhancing Structural Integrity with Advanced Epoxy Injection Solutions

Bridges serve as vital arteries for transportation and commerce, constantly bearing the brunt of heavy traffic and exposure to harsh environmental conditions. Over time, this wear and tear can lead to cracks and other structural issues that compromise their integrity. Addressing these problems promptly is critical for ensuring public safety and the longevity of these essential infrastructure elements.

When it comes to repairing bridge cracks, contractors and engineers are turning to cost-effective and efficient solutions like structural epoxy injection. This technique has proven to be an industry-standard for restoring the structural integrity of bridges without the costly and time-consuming process of complete replacements.

Structural Epoxy Injection:

A Reliable and Cost-Effective Solution for Bridge Crack Repair

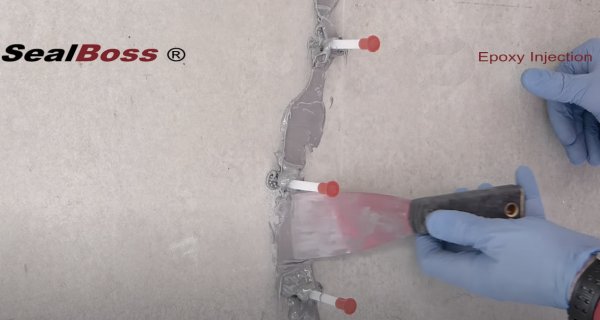

Structural epoxy injection is a cutting-edge method that involves injecting specially formulated epoxy resins into cracks. These resins fill and bond the gaps, significantly enhancing the strength and stability of the entire structure. Let us explore why epoxy injection is a preferred solution for bridge crack repair.

Structural epoxy injection offers several benefits, including:

- Cost-effectiveness: By utilizing structural epoxy injection, unnecessary expenditures on demolishing and rebuilding can be avoided. This approach cuts down on both material and labor costs, making it a budget-friendly solution.

- Time savings: Compared to traditional repair methods, structural epoxy injection is significantly faster, leading to minimal disruptions and reduced downtime for bridge traffic.

- Versatility: Whether the bridge is made of concrete, steel, or masonry, epoxy injection can effectively repair a wide range of structural materials, making it a versatile choice for diverse bridge designs

- Improved strength and structural performance: Beyond simply repairing existing cracks, epoxy injection e3nhances the overall performance of the structure by improving load-bearing capacity of the bridge and providing resistance to future environmental stressors and wear.

Professional Equipment for Successful Bridge Crack Repair

Achieving optimal results in bridge crack repair relies heavily on utilizing professional-grade equipment. SealBoss offers a comprehensive suite of tools and materials to ensure precision and efficiency in structural epoxy injection projects.

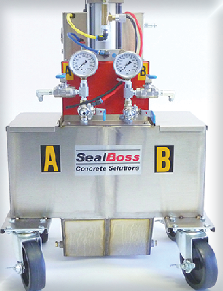

SealBoss PA3000 Epoxy Injection Pump

The SealBoss PA3000 epoxy injection pump stands out as a pneumatic powerhouse designed for handling extensive bridge crack repair projects and many linear feet of structural epoxy injection per day. With a large stainless steel reservoir and dual-component capabilities, it delivers a continuous flow of epoxy for uninterrupted injection.

Key features of the SealBoss PA3000 epoxy injection pump include:

- User-Friendly Design: Designed with ease of operation in mind, minimal training is needed for contractors to operate this pump efficiently, reducing setup time and increasing productivity.

- High performance: Capable of maintaining consistent epoxy delivery throughout the day, the pump enables seamless and efficient crack repairs, especially in high-traffic areas.

- Versatility Across Applications: The SB PA3000 can be used for various applications, including crack repair, bonding, and sealing in bridges, tunnels, dams, and other critical civil engineering infrastructures

- Durability for Harsh Conditions: With robust construction and a modular design, the SealBoss PA3000 is built for easy maintenance and to withstand tough worksite conditions, ensuring long-lasting reliability.

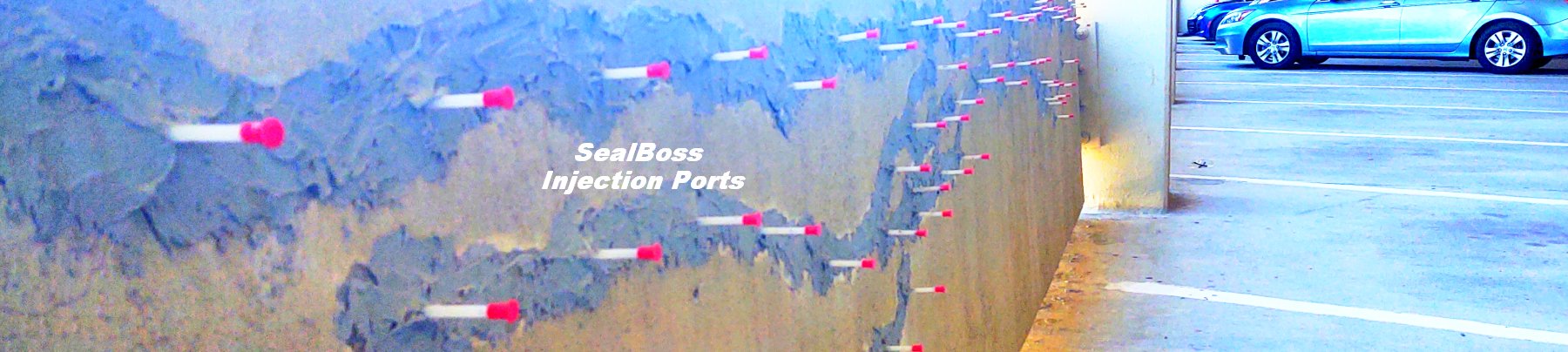

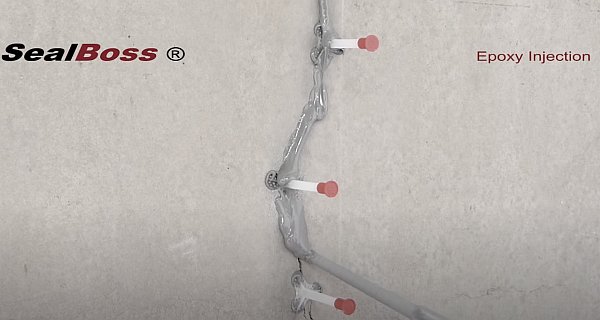

SealBoss Epoxy Injection Ports

SealBoss® Epoxy Injection Ports provide versatile, durable solutions for various epoxy crack injection needs. Engineered to integrate seamlessly with SealBoss Epoxy systems, they support manual, pneumatic, pump, cartridge, and high-pressure applications. Designed to handle rough surfaces, corner cracks, and high-pressure scenarios, these ports offer specialized options like angled and round base designs for efficient and reliable performance.

Key Benefits of SealBoss Epoxy Injection Ports include:

- Versatile Design: Four durable port designs for varied conditions.

- Comprehensive Compatibility: Supports manual, pneumatic, pump, cartridge, and high-pressure injection methods.

- Specialized Solutions: Angled ports for corners and round base ports for shallow drill holes.

- Reliable and Efficient: Seamlessly integrates with SealBoss systems for optimal performance.

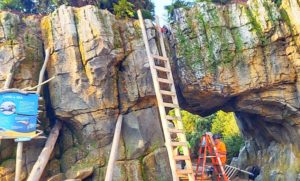

Montana Department of Transportation

A Real-World Example: Montana DOT Bridge Crack Repair Restoration Project

The Montana Department of Transportation (DOT) has recently released an extensive work plan covering multiple bridge restoration initiatives, which involve the use of structural strength epoxy resin systems for crack injections.

A leading construction firm was tasked with the responsibility of executing these repairs. The project entails the injection of structural epoxy resin into specified cracks utilizing the SealBoss Epoxy Injection System.

The core elements of this repair strategy included:

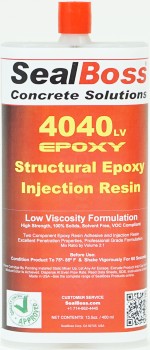

- SealBoss 4040 LV Structural Epoxy Resin: A low-viscosity, structural strength resin formulated for deep penetration into narrow cracks.

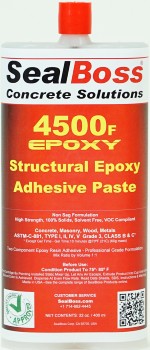

- SealBoss 4500F Crack Seal and Port Setting Paste: Ensuring secure adhesion and setting of injection ports.

- SealBoss Tri-Base Surface Mount Injection Ports: Facilitating precise injection of resin into targeted areas.

- SealBoss PA3000 Epoxy Injection Pump: Delivering consistent and reliable performance throughout the project.

During this project, SealBoss regional manager Chris Conderre conducted a detailed on-site training session covering the operation and maintenance of the SealBoss PA3000 epoxy injection pump.

The training also emphasized the correct usage of accessories such as static mixers, Tri-Base Plastic Epoxy Injection Surface Mount Ports, and all connecting equipment required establishing a flawless union between the applicator and the substrate.

Conclusion

Reliable Bridge Crack Repair Solutions for the Future

Bridge crack repair using structural epoxy injection is a cost-effective and dependable approach that meets the needs of modern infrastructure maintenance, contractors and engineers.

By employing advanced equipment like the SealBoss PA3000 epoxy injection pump, along with high-quality materials such as the SealBoss 4040 low viscosity structural epoxy resin and the SealBoss 4500F crack seal and port setting paste, contractors can achieve exceptional repair results while minimizing downtime and costs.

Furthermore, proper training and education on the usage of these advanced tools and techniques are critical in achieving the desired outcomes.

As the demand for reliable and cost-effective bridge crack repair solutions continues to grow, it is essential for contractors and engineers to stay updated with the latest advancements in technology and materials. By adopting innovative methods like structural epoxy injection and utilizing state-of-the-art equipment, industry professionals can ensure the longevity and safety of bridges and other vital infrastructure components.

In summary, bridge crack repair using structural epoxy injection and advanced equipment like the SealBoss PA3000 epoxy injection pump offers numerous benefits. By adopting solid injection techniques and professional equipment, contractors and engineers can ensure the safety, reliability, and longevity of bridges and other critical infrastructure components, ultimately benefiting the communities they serve.

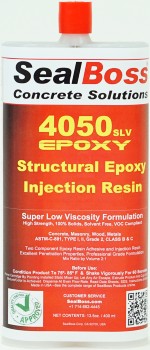

Structural Epoxy Injection System Products Used

- Injection Resin: SealBoss 4040 LV Structural Epoxy

- Surface Anchoring Paste: SealBoss 4500F Quick Seal Paste

- Injection Ports: Surface Mount Tri-base Ports

- Epoxy Pump: PA3000 2:1 Dual Component Injection Pump

- R70 Pump Flush

By leveraging these innovative techniques and equipment, contractors can confidently tackle bridge crack repair projects, reinforcing the durability and safety of crucial transport infrastructure for years to come.

Related Links

SealBoss Surface Mount Epoxy Port Selection

Click on each picture to learn more