Basement Crack Repair

Basement Crack Repair

Basement Crack Repair - Injection Techniques

Introduction:

Maintaining the integrity of your home’s foundation is crucial, especially when dealing with basement wall, floor, and foundation cracks. These issues, if neglected, can escalate into major structural and moisture-related problems. This guide offers a concise overview of effective basement crack repair methods, including the use of polyurethane foam for waterproofing and epoxy resin for structural reinforcement.

Understanding how to properly address these cracks is key to preserving your home’s stability and value, ensuring a safe and dry basement environment. Through exploring various repair techniques, homeowners can find the most suitable approach to protect their foundation and extend the lifespan of their property.

Basement Wall, Floor, and Foundation Crack Repair

A Guide to Basement Crack Repair: Preserving the Integrity of Your Home’s Foundation

Your home’s basement is more than just a storage space; it is the solid base that holds your house together, literally. Consequently, it is critical to keep it in peak condition.

Over time, however, the basement might start showing signs of wear and tear, such as basement cracks. These fissures can be attributed to various factors, including drying shrinkage, thermal movement, shifting foundations, and foundation settling. Errors in the concrete mixing and application processes during construction can also contribute to the problem.

These basement cracks, seemingly harmless at the onset, can progressively multiply and widen. This deterioration can then lead to water seepage, causing a damp environment conducive to mold growth. This can also lead to a musty smell and even a significant compromise to the structural integrity of your home. The implications of these issues extend to the quality of living in the home and its market value. Therefore, maintaining a stable and dry basement environment, synonymous with a sound foundation, is of utmost importance.

Despite basement cracks being a relatively common occurrence, it is not advisable to ignore them. Homeowners should make it a habit to inspect the foundation wall and floor in their basement for any concrete cracks. Any identified issues should be promptly addressed to prevent further deterioration.

Approaches to Basement Crack Repair

There is a multitude of approaches to tackling basement crack repair. The method most appropriate is determined by the extent of the damage and the unique environmental conditions of the space.

Utilizing polymer resins and foams for injection constitutes an efficient and economical approach to mitigate basement leaks and restore structural integrity to basement walls and foundations.

Depending on the chosen products, these methodologies provide not only a pragmatic resolution to leakage problems but can also significantly enhance the durability and structural stability of the existing infrastructure. It is vital to discern between dry and wet basement cracks and understand their structural implications.

- Resolving Water Intrusion with Polyurethane Foam Basement Crack Injection

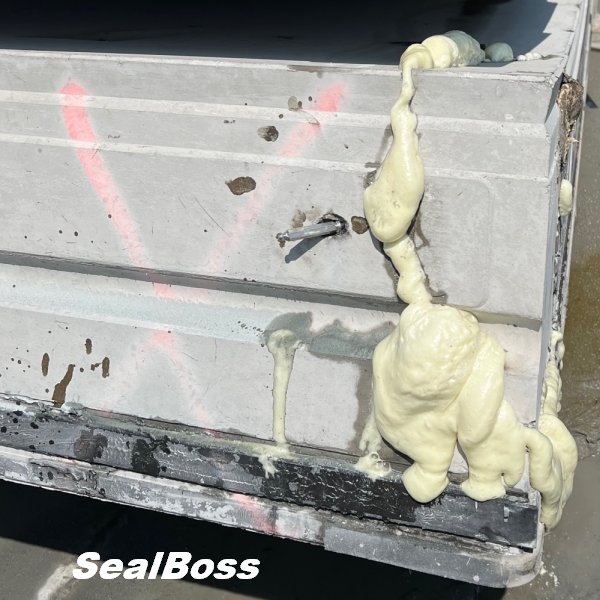

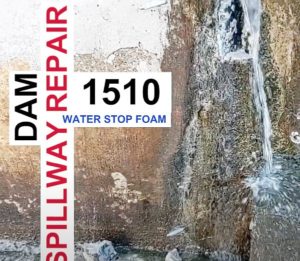

Water intrusion through basement cracks can cause significant damage, leading to problems like mold growth and property depreciation. The introduction of basement crack injection with polyurethane foam has revolutionized the way these issues are addressed. Polyurethane foam expands upon contact with moisture, making it an excellent solution for sealing cracks and preventing water ingress. The foam fills the entire crack and forms an impermeable barrier against further water intrusion. This injection process is carried out from inside the structure, reducing the need for extensive excavation and offering a cost-effective, efficient solution for water intrusion concerns. - Strengthening Structures with Epoxy Resin Basement Crack Injection

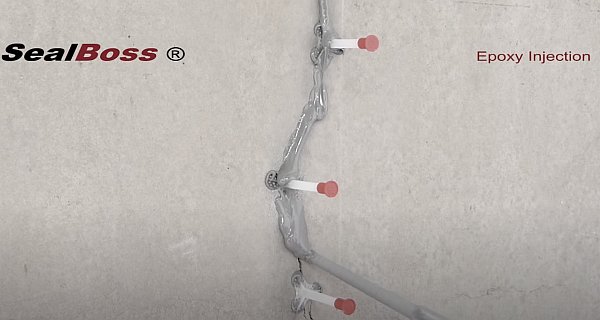

For structural repair in basements, the crack injection process utilises epoxy resin, known for its high strength and durability. The injected epoxy hardens within the crack to form a rigid seal of high compressive and tensile strength, effectively restoring the structural strength of the cracked concrete. This process results in a permanent repair, reinforcing the structure and enhancing its longevity. By employing basement crack injection with epoxy resin, homeowners can ensure the maintenance of structural integrity, enhancing the safety and value of their properties.

The location of basement cracks often determines the extent of water permeation they may cause. In numerous scenarios, the primary goal is to establish a barrier against such seepage, necessitating the sealing of these cracks with polyurethane based products rather than enhancing their structural strength.

Conversely, there are situations where the restoration of structural stability of the wall or foundation becomes the primary objective. In these instances, epoxy resins emerge as the preferred choice due to their superior strength and bonding properties.

To understand this distinction more comprehensively, we recommend reviewing the Epoxy/Polyurethane Comparison article, which provides an in-depth analysis of the differential uses and benefits of these two material groups in basement crack repair.

Injection from the Inside – No Digging Required

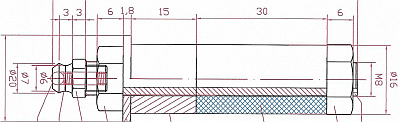

A prevalent and convenient method of sealing cracks in concrete and concrete/cinder block basement walls is by injecting them from the inside. This repair process typically involves injecting polyurethane or epoxy crack materials into the cracks, offering a robust solution to water seepage and structural issues.

Concrete Structures

For cracks in poured concrete foundation walls, a monolithic and solid structure, a direct injection of chemical polyurethane grout or epoxy resin is the method of choice. The polymers fill the cracks and voids, and seal the structure in the process.

Poured Concrete versus Block Walls

Basement crack repair for concrete/cinder block foundation walls can present a different set of challenges. These walls, unlike poured concrete structures, are not monolithic. They are porous and constructed from numerous pieces held together with mortar, creating an abundance of cold joints, a convenient route for water penetration.

A cold joint is defined as the surface where an existing substrate and a fresh substrate, in this case, mortar, form a non-monolithic gap with no or very low bond strength. Due to these characteristics, block walls are usually more challenging to seal by direct injection. These often necessitate more extensive methods like curtain or bladder injection — moving chemical grout behind the structure from an inside injection grid pattern — to ensure water tightness.

Thankfully, in many situations — and more easily with poured concrete walls than block walls, for the reasons explained above — basement wall cracking can be remedied with basement crack repair kits. It is always recommended to get advise from a professional and licensed contractor prior to deciding on a crack repair strategy and a specific basement crack repair system.

To aid in your research, we’ve included links to some highly-rated basement crack repair kits, offering practical solutions for sealing basement wall and floor cracks. These resources, alongside additional crack repair-related information, will help you make an informed buying decision.

In conclusion, it is important to take basement cracks seriously, no matter how small or insignificant they might seem. While the task may seem daunting at first, remember that there are resources available to help. From basement crack repair kits for smaller tasks to professional contractors for larger projects, you have options. Therefore, do not neglect your basement; give it the care it needs, and it will support and protect your home for many years to come.

Addressing Basement Crack Repair – Reach Out to Us at 714-662-4445

Take note, the phenomenon of broadening cracks in basement walls and floors, which may result from persistent foundation settling or sinking, can often be corrected using chemical grout injection techniques associated with crack injection. This includes procedures such as under slab void filling and polyjacking methods.

Basement Crack Repair Information

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.

This newer water treatment plant has the capacity to meet the needs of the growing city’s population and industrial demands. It utilizes state-of-the-art technology to reduce seasonal taste and odor issues, treats for sulfates from Devils Lake discharges, and meets regulatory requirements related to pharmaceuticals, pesticides and herbicides. Located in a harsh climate, the Treatment Plant is an all indoor facility with multiple basins for the various processes of treatment.