Tunnel Water Stop Injection Leak Repair

Tunnel

Water Stop

Injection

Leak Repair

Leak Sealing

Systems

Tunnel Water Stop Injection Leak Repair with Polymer Grout Injection

Introduction:

Tackling Water Leakage in Tunnels: Challenges and Solutions

Water intrusion is a persistent challenge in tunnel infrastructure, affecting safety, durability, and operational efficiency. This article explores the risks associated with water leaks in various tunnel types—utility, vehicle, subway, rail, and pedestrian tunnels—and presents advanced solutions for effective sealing and structural reinforcement.

A key focus is the use of Polymer Injection Grouts, particularly acrylate gels and polyurethane resins, which offer reliable waterproofing and long-term stability. We delve into the properties and applications of these materials, outlining a step-by-step approach to leak diagnosis, material selection, and injection techniques.

Additionally, the article highlights SealBoss’s specialized products designed for underground water ingress repair, emphasizing the critical role of proper training and equipment for successful application. Whether addressing minor seepage or severe structural leaks, this guide provides essential insights for ensuring tunnel integrity and longevity.

Tunnel Water Stop Injection Leak Repair Overview

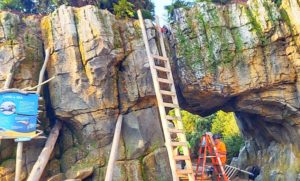

Tunnels, essential to modern infrastructure, vary in design and function but share a common challenge—water intrusion. Below is an overview of the tunnel types most susceptible to leaks and the potential risks they face:

Utility Tunnels – These tunnels house essential systems such as electrical wiring, water pipes, and gas lines. Water infiltration can lead to pipe corrosion, electrical failures, and even hazardous gas leaks, compromising both safety and service reliability.

Vehicle Tunnels – Water seeping through tunnel walls or accumulating on road surfaces creates hazardous driving conditions. Pooled water can reduce tire traction, increasing the risk of skidding, accidents, and severe traffic disruptions.

Subway Tunnels – Built beneath densely populated urban areas, subway tunnels are highly vulnerable to leaks from surrounding soil and aging infrastructure. Persistent water intrusion can disrupt train operations, cause service delays, and lead to costly maintenance and repairs.

Rail Tunnels – Water intrusion in rail tunnels poses significant risks, particularly to electrical components and track stability. Excess moisture can weaken the track bed, cause rail misalignment, and in extreme cases, contribute to derailments.

Pedestrian Tunnels – Water leaks in pedestrian tunnels create slippery surfaces, increasing the risk of slips and falls. Persistent dampness also encourages mold and bacteria growth, leading to poor air quality and potential health hazards.

Waterproofing and leak repair solutions are essential to maintaining tunnel safety, functionality, and longevity. Addressing water intrusion early can prevent costly damage and serious operational disruptions.

How to stop leaks of high hydrostatic pressures with Injection Grouts

Water ingress can cause immediate damages as well as lead to increased project costs and may lead to many other issues down the line.

Water ingress poses both immediate and long-term challenges, driving up project costs and leading to structural deterioration if left unaddressed.

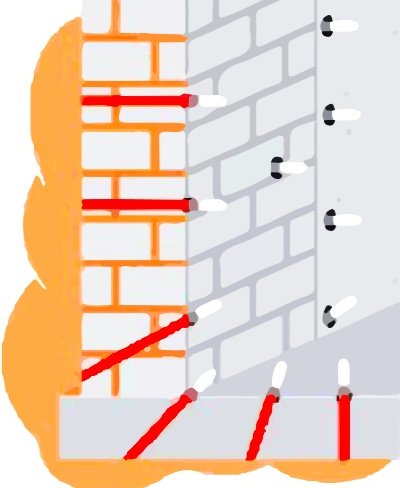

Leaks through cracks, joints, and voids can be effectively sealed using advanced injection systems that employ cost-efficient and highly reliable chemical grouts, such as multi-component acrylate gels and single-component polyurethane resins.

When properly engineered, resin injection systems do more than just stop leaks—they also stabilize surrounding soil by transforming loose sands into a firm, sandstone-like consistency and consolidating gravel into a bonded, load-bearing structure. This not only enhances the durability of the tunnel but also improves its overall resilience against future water intrusion.

Example: SealBoss Acrylates Used to Seal Leaks in Tunnel

What are Acrylate Gels?

Acrylate gels, also known as acrylic gels, are highly flexible, ultra-low viscosity, hydrophilic sealing agents designed for non-structural injections. With a consistency similar to water, they effectively penetrate cracks, joints, and voids, making them ideal for grid, curtain, and bladder injection applications, as well as use in injection tube sealing systems.

Thanks to their exceptionally low viscosity and surface tension, polyacrylate gels offer superior penetration capabilities, allowing them to reach even the smallest fissures. Their adjustable gel time enables precise application, adapting to varying job site conditions such as temperature and injection distance.

When in contact with water, acrylic gels expand hydrophilically, creating a compression seal that prevents further leakage. This swelling behavior makes them an effective solution for waterproofing applications. Additionally, acrylate injection equipment can be easily cleaned with water, simplifying maintenance.

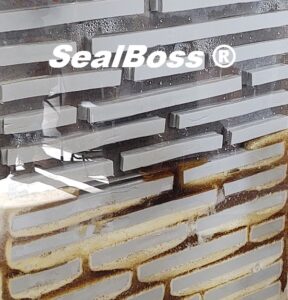

SealBoss provides a comprehensive range of high-performance products designed to control water ingress in underground mining operations, tunnels, and other commercial structures facing leakage challenges. Our solutions support waterproofing, soil consolidation, crack and joint repair, sealing, bonding, and cavity filling, ensuring durable and long-lasting protection.

Tunnel Water Stop Injection Leak Repair

How to Start Acrylate Injection Leak Sealing Injection Repairs

The principal steps to solve a problem are:

- Diagnosis of the problem

- Specification of injection methods

- The correct choice of resin, pumps, packers and accessories

- Training of installation personnel, a well trained and experienced team is paramount

Will I need more than One Product?

That depends on the conditions of the jobsite. Polyurethane and Acrylate injection systems offer a variety of solutions to problems found in geotechnical applications, in tunneling, waterproofing underground works and civil engineering in general. While there is no single resin that will suit all conditions, the correct resin must be used to achieve the best results possible and to meet the requirements of the specification.

If there are any questions about the various chemical grouts available, please do not hesitate to contact us, we are here to assist in any way we can. Always remember to work safely by wearing eye protection and gloves when handling any type of chemical systems.

Which products are shown in the videos?

Products used for Tunnel Water Stop Injection Leak Repair

Related Article

Call Your SealBoss Technician

If you have any questions on crack injection water stop procedures or any injection related applications, please contact our team of qualified SealBoss representatives to schedule an on site consultation & full injection systems training. Call us at 714-662-4445.