The Challenge of Leaking Canals

The network of irrigation canals that crisscross agricultural regions is vast and complex. Managed by various entities, including the Bureau of Reclamation, this infrastructure spans thousands of miles and is crucial for the delivery of water to farmlands. However, the aging of these canals, combined with natural and mechanical damages, presents a continuous battle against leaks and seepage. Such issues not only lead to water loss but also pose significant risks to the structural integrity of canals, potentially resulting in erosion, sinkholes, and even catastrophic breaches that can have far-reaching impacts on agriculture and nearby communities.

Advanced Solutions for Irrigation District Canal Sealing

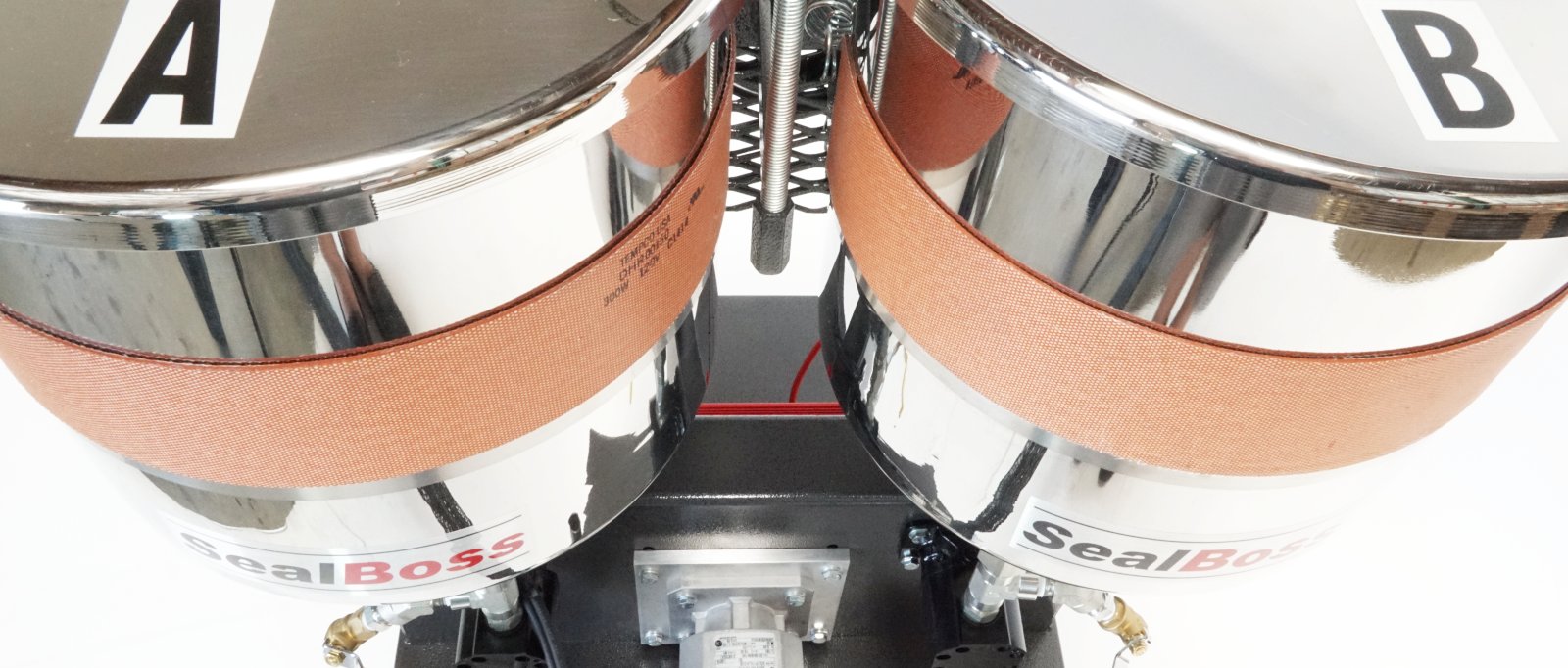

Polyurethane Grout Injection

Polyurethane grout injection stands out as a modern solution for addressing irrigation canal leaks. This method involves injecting a liquid polymer, which expands upon contact with moisture, into cracks and voids, thereby creating a durable, watertight seal. The rapid curing time of polyurethane grout minimizes downtime in water delivery, and its flexibility allows the structure to accommodate future movements, significantly reducing the likelihood of recurrent leaks.

Using NSF Drinking Water Contact Certified Polyurethanes

NSF-approved polyurethane grouts are essential in irrigation canal sealing because they meet stringent safety standards by the National Sanitation Foundation (NSF) and the American National Standards Institute (ANSI). This certification ensures these materials are safe for use in environments in contact with potable water, preventing contamination. SealBoss NSF/ANSI/CAN 61 Certified Products undergo rigorous testing to ensure they do not leach harmful contaminants, making them a reliable choice for maintaining the purity of water systems and complying with regulatory requirements for public health and environmental protection.

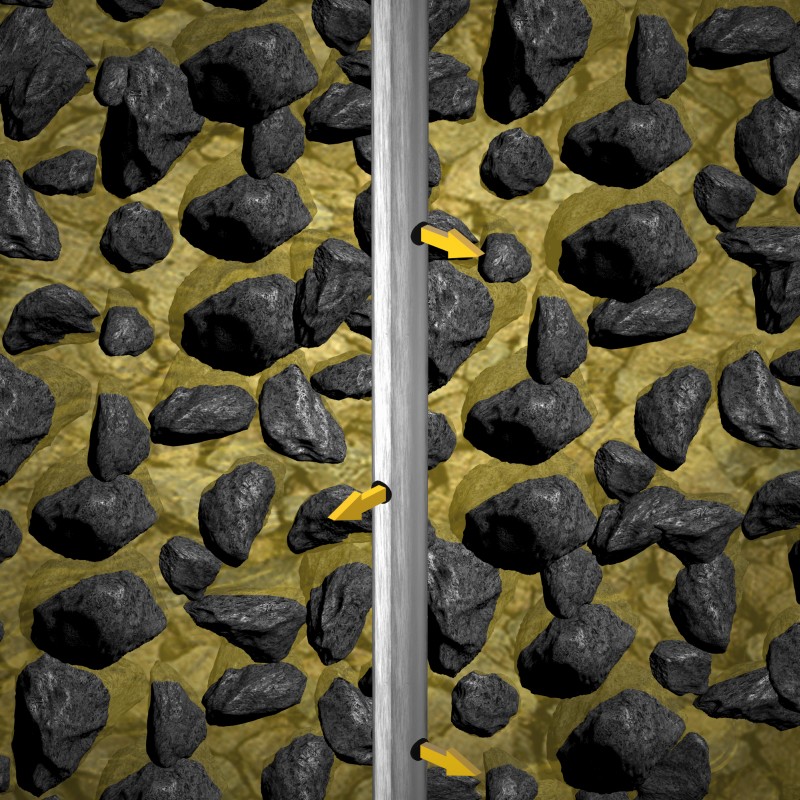

Addressing Seepage with Curtain and Probe Grouting

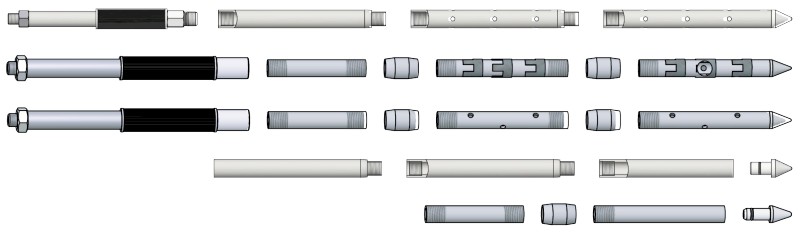

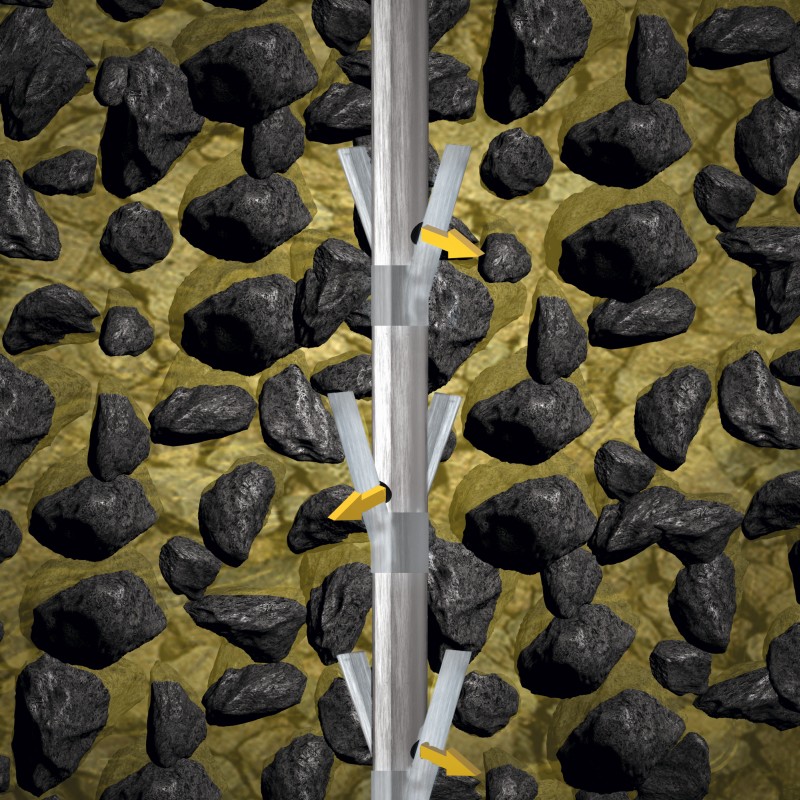

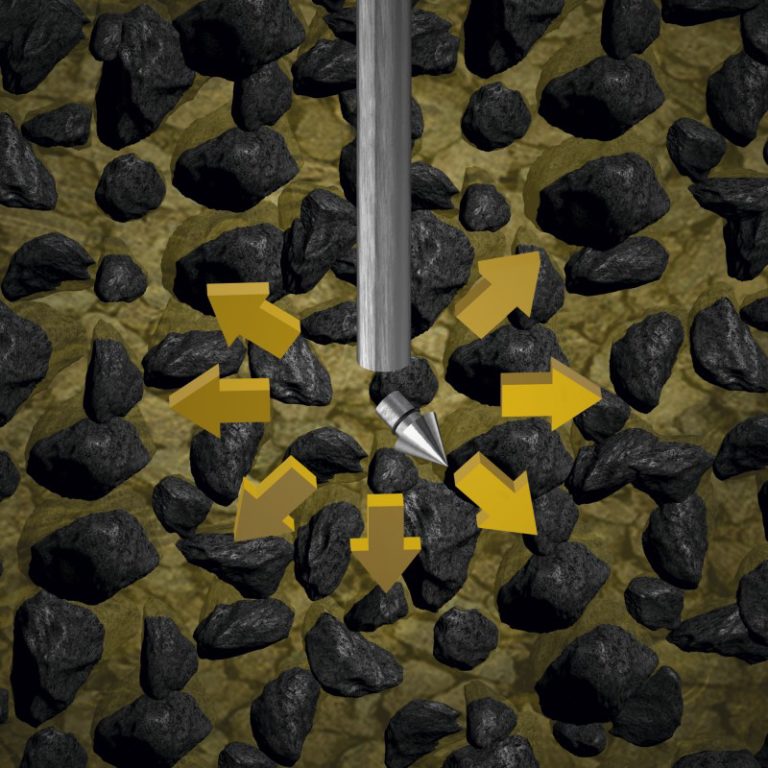

In addition to direct crack sealing, addressing pervasive seepage is critical for maintaining the functionality and integrity of irrigation canals. Techniques such as curtain and probe grouting play a crucial role in this context. Curtain grouting involves creating a grout barrier along the canals wall to block water pathways into the soil, while probe grouting with injection lances targets specific seepage paths, allowing for precise application and minimal environmental disturbance.

Steel Injection Lances, tailored for specialty grouting applications, facilitate the delivery of various polymer solutions directly into the soil. Their primary function is to inject these polymers deep into the soil to enhance its properties. By doing so, they significantly increase the soil’s strength, decrease its permeability, and improve its overall stability, making them indispensable tools for polymer leak sealing and soil stabilization efforts.

Sealing Joints in Concrete Canals

Concrete-lined canals face the challenge of leaking panel joints. SealBoss 1510 Water Stop Foam, used in conjunction with SealBoss Oakum, provides an effective solution for sealing these joints. The combination of these materials forms a water-impermeable barrier, ensuring the longevity and functionality of lined canal systems.

Grout-Impregnated Oakum

Grout-impregnated oakum represents a blend of traditional and modern repair techniques. Utilizing SealBoss Oakum—a fibrous material derived from old hemp ropes—saturated with specially formulated grout, this method can effectively be used to seal wider cracks and seals cracks and joints in irrigation canals. The natural flexibility of oakum, combined with the strength of the grout, offers a resilient barrier against water seepage, making it especially suitable to seal irregular and wide cracks, as well as leaking joints.

Soil Cavity Filling and Sealing

The stability and functionality of irrigation canals are compromised not only by the effects of soil erosion and washouts but also by the presence of wildlife, which presents unique and significant challenges.

Animals like gophers, muskrats, and beavers can create tunnels and burrows in canal berms, potentially leading to significant water loss and instability. Sealing these wildlife burrows with quick expanding SealBoss polyurethane foam grout not only prevents water leakage but also deters animals from re-establishing their burrows, thereby protecting the canal and adjacent agricultural lands from unintended water damage.

The Importance of Professional Expertise

While some maintenance tasks pertaining irrigation district canal sealing can be handled through do-it-yourself approaches, the complexity of canal repair often necessitates professional expertise. Companies like SealBoss offer comprehensive guidance and technical support tailored to the unique challenges of canal maintenance. Their referrals to experienced contractors ensure that repair projects are executed effectively, safeguarding this critical infrastructure against the myriad challenges it faces.

Conclusion

The sustainability of our agricultural system relies heavily on the integrity of irrigation canals. Through the application of advanced sealing techniques and materials, combined with professional expertise, we can ensure the efficient delivery of water to farmlands, preserving the foundation of agricultural productivity and environmental stewardship for future generations.

Related Links

Structural Irrigation Canal Concrete Repairs

Related Article

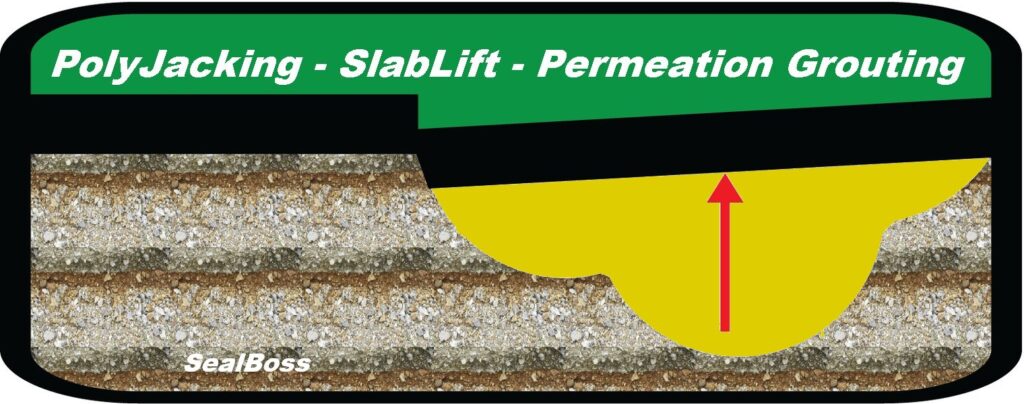

Slab Lifting, Soil Compaction, Permeation, and Consolidation Injection Systems

Slab Lifting, Soil Compaction, Permeation, and Consolidation Injection Systems