Injection Packers

Injection Packers for High Pressure Crack Injection Applications Overview

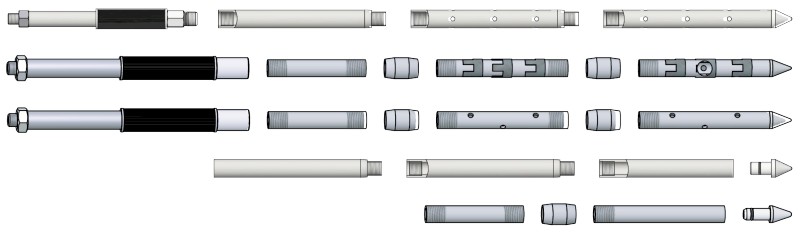

- Injection Packer Materials – Injection Packers bodies are constructed from various materials including steel, brass, aluminum, zinc, or plastic.

- Dimensions – Injection Packers are available in many sizes, lenghts and diameters to meet the application demands, injection products, injection pressures, and injection volume and flow requirements.

- Mechanical Packers – Injection Packers, specifically the mechanical injection packer types, short “Mechanical Packers”, are fitted with a compression rubber sleeve mechanism, to lock securely into the packer placement drilled hole.

- High Injection Pressures – Mechanical Injection Packers, are designed to work in high pressure injection conditions from several hundred psi up to several thousand psi. (100 – 10,000 psi or 6 – 600 bar).

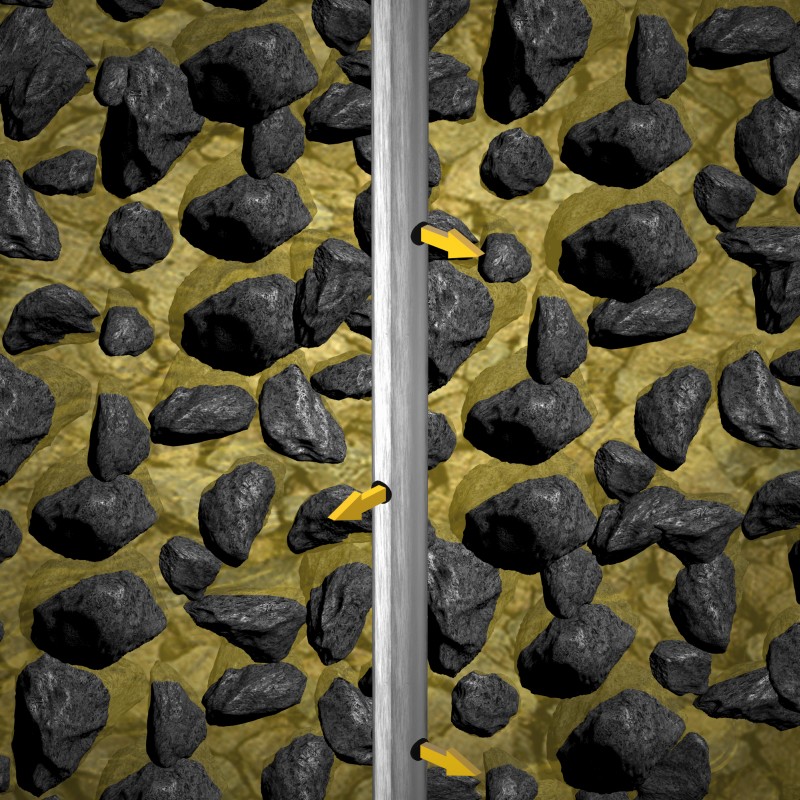

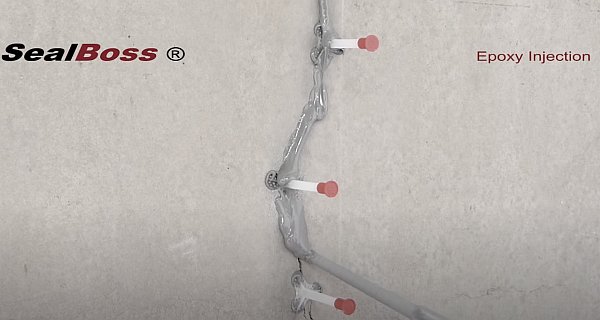

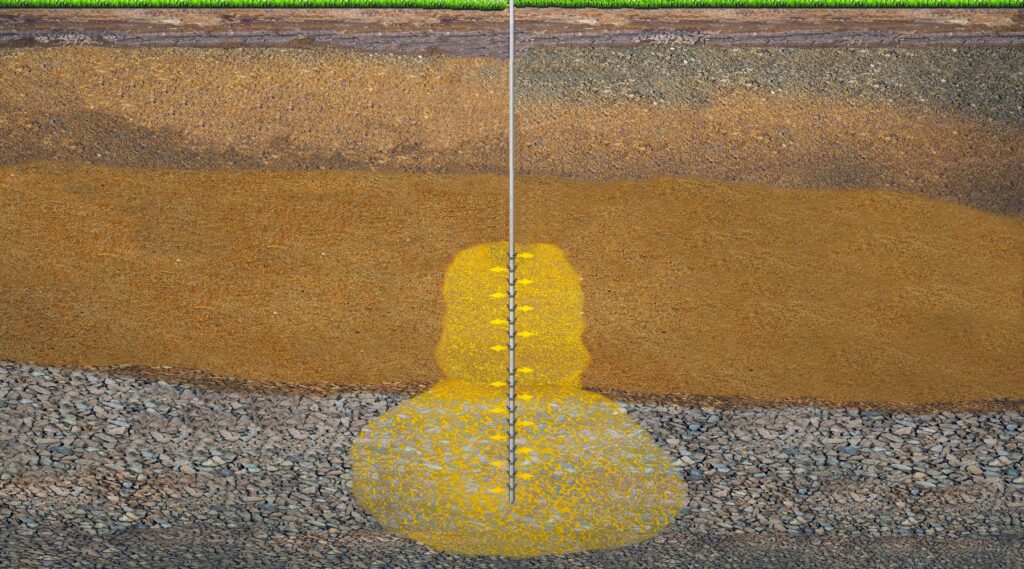

- Injection Packer Application Procedures – Injection Packers are often placed in a staggered pattern along the crack in a 45 degree angle. This is known as the standard SealBoss 1 – 2 – 3 – 45 Degree Method. Other methods and packer placement techniques also apply depending on the requirements of the application.

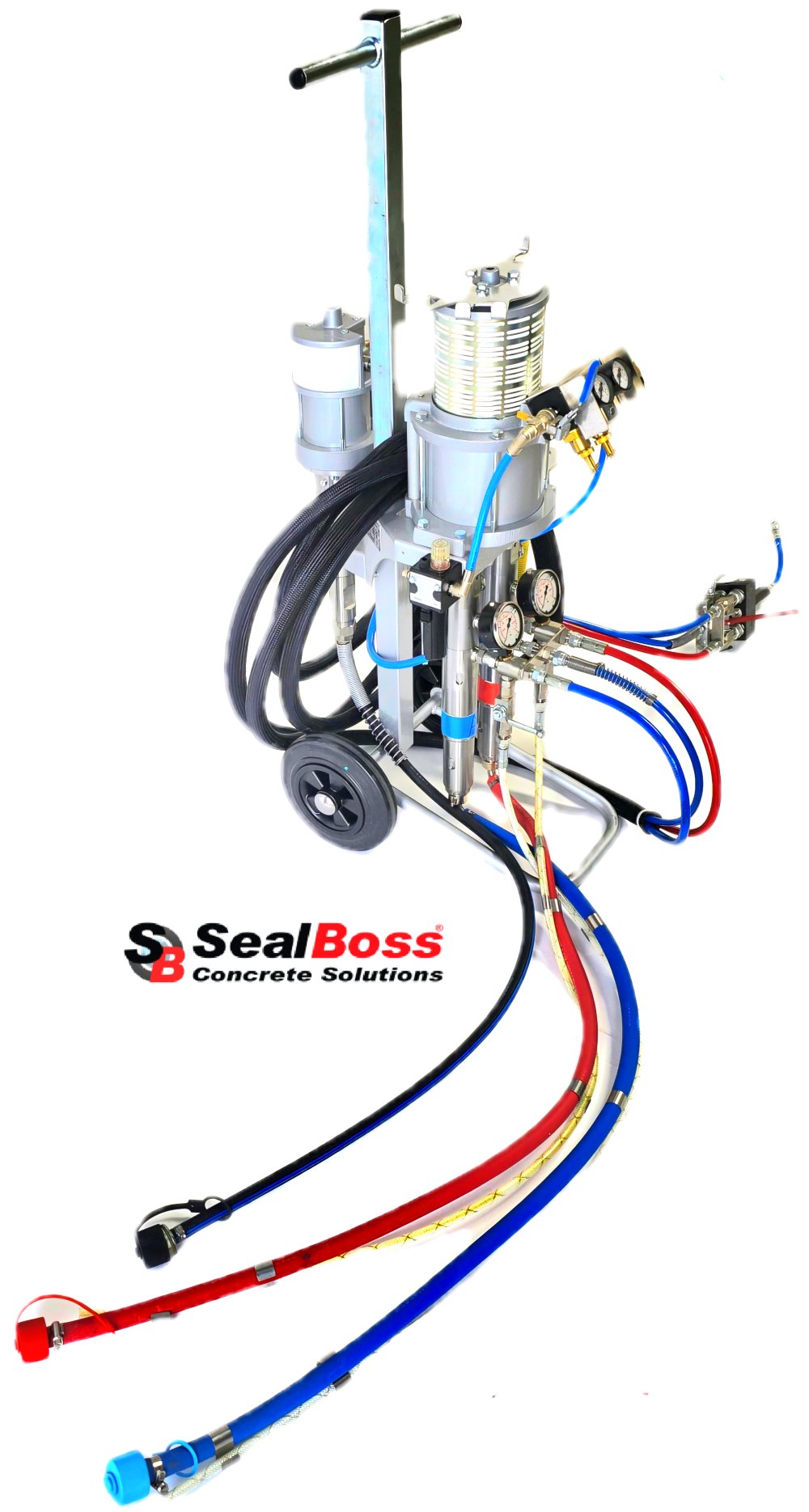

Injection Packers are designed to safely and securely connect your Injection Equipment to the concrete substrate, in order to deliver the injection chemical resin – often under high injection pressures – to the area of repair.

Injection packers must be of suitable construction and sturdiness, as they have to withstand low and high injection pressures as needed, and allow for adequate flow of product. Their design must permit easy installation and removal, as needed – while being cost- effective.

Injection Packers Details Explained

Information About Injection Packers

Packer Materials & Types

Injection packers and ports are essential tools for successful grout and epoxy injection in construction and repair projects. These tools are generally categorized into two types: insertable mechanical injection packers and surface-mounted ports.

SealBoss offers a wide selection of injection packers made from steel, brass, aluminum, zinc, various metal alloys, and plastic.’

Each material and design caters to specific substrates, applications, and contractor preferences, ensuring a tailored solution for any injection scenario.

Mechanical Injection Packer Features

Premium mechanical packers incorporate a rubber sleeve with a threaded shaft. When tightened, the sleeve compresses to form a seal within the drilled hole. A soft, expandable rubber ensures optimal grip and supports high injection pressures.

SealBoss Steel Injection Packers are most robust, high-performance packers designed for high-pressure resin injection in demanding applications.

Known for their strength and durability, SealBoss steel packers are suited for high-pressure injections, icnluding polyurethane, epoxy, and acrylate/acrylic gels. Available in multiple designs, most include a rubber sleeve and a larger top washer for secure installation.

These packers are an efficient, industry standard setting, and effective solution for structural repair and waterproofing, trusted by professionals worldwide.

- Steel Construction Injection Packers: Set the standard – built to withstand high injection pressures and provide a durable, reliable seal.

- Interchangeable Fittings: Come with button head and standard and low pressure zerk fitting options, enhancing versatility for various injection systems.

- Anti-Return Valve: Located in the fitting, it prevents resin backflow, maintaining the integrity of the injection.

- Port-to-Port Resin Travel: Removeable valve allows for observation of resin movement, ensuring controlled application.

- Wide Size Range: Suitable for various applications, from small repairs to large-scale projects.

- Compatibility: Works with all injection resins, including low-pressure applications.

Brass, Aluminum, and Zinc Packers

These materials offer economical alternatives to steel with similar functionality. Although they have lower strength, some designs allow the shaft to be broken off after injection, leaving a flush surface—a benefit for certain projects.

SealBoss Aluminum Injection Packers are economical, lightweight options for standard resin injection tasks.

Modeled after the SealBoss S-Type steel, these aluminum packers offer a very budget-friendly solution for typical crack injection scenarios, ideal for professionals looking to reduce costs on routine jobs.

- Aluminum Construction: Provides a secure fit and is lighter and more affordable to ship than steel alternatives.

- Cost-Effective: The most economical option for crack injection, saving costs on large projects.

- Anti-Return Valve: Located in the zerk fitting, preventing resin backflow during application.

- Standard Application Use: Suitable for everyday injection needs and non-critical applications.

SealBoss Brass Injection Packers are durable and versatile packers designed for resin injection.

These economical alternatives to steel packers are widely used in construction for their built in zerk fittings, reliability and cost-effectiveness.

- Available in a Wide Variety of Sizes, Thicknesses, and Lengths: Options range from compact to extended-length injection packers, designed to meet the most demanding jobsite requirements.

- Monolithic Zerk Fitting:No separate zerk fitting ensures smooth installation procedure and secure attachment.

- Anti-Return Valve in the Packer Base: Prevents resin backflow, even if the neck is unscrewed or broken off.

- Defined Breaking Point: Allows clean removal after use.

SealBoss Standard Zinc Packers are strong, affordable, and reliable packers designed for standard grout injection.

Zinc injection packers are another choice for general injection applications, offering quick installation and efficiency in everyday crack repair and sealing tasks.

- Bottom Anti-Return Valve: Enables head removal after grout injection, preventing backflow.

- Packer Neck Hexagon: Easy tightening packer neck

- Common Industry Size: Provides adequate surface seal area for a secure grip at an economical price.

SealBoss Plastic Buttonhead Injection Packers and Hammer-In Ports for large Volume Injection nad Fast Installation.

These plastic packers offer versatile options for resin grout injections, covering applications that metal-style injection packers may not accommodate.

The SealBoss Hammer-In or Bang-In packers require only a hammer to secure in place. These packers create a compression seal without a sleeve, making them ideal for quick installation. However, they are best suited for low-pressure injections due to a lower friction fit.

- Buttonhead Packers: Feature a large anti-return valve and inner diameter for high-volume material flow, ideal for low-pressure applications like curtain injection and slab lifting.

Hammer-In Ports: Quickly installed without the need for tightening, providing a fast, economical alternative to mechanical packers in certain applications. - Wide Compatibility: Suitable for use with epoxy, grout, and various SealBoss injection systems, including manual, pneumatic, and cartridge injections.

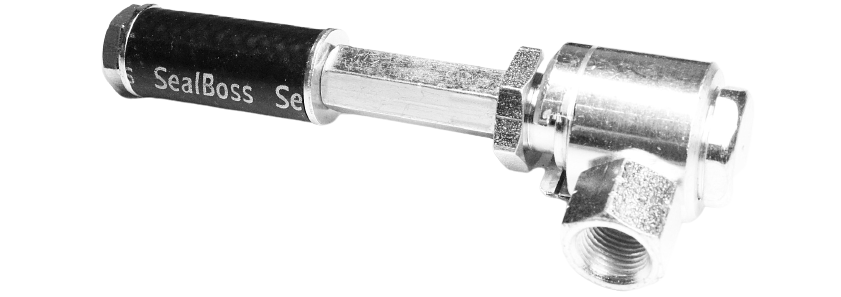

Injection Packer Fitting Types

Packers often feature either a zerk or button head fitting for connection:

- Zerk Fitting: Commonly used for medium to high-pressure applications, offering quick connection and disconnection.

- Button Head Fitting: Suitable for high-volume applications, providing a superior connection with reduced leakage, especially beneficial for single-operator use.

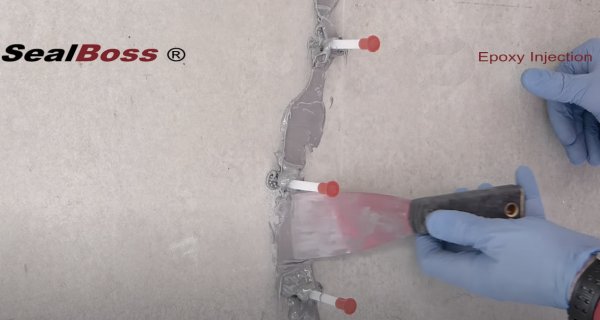

Surface Ports

Surface-mounted epoxy injection ports are suitable for lower-pressure applications or when drilling isn’t feasible. They can be glued directly to the surface or placed within a drilled hole. Many have open designs for quick-release connectors and are equipped with caps to prevent backflow. Ports with zerk fittings are available for higher pressure needs, including specialized corner ports for 90-degree angles.

Injection Packer Dimensions and Specifications

Diameter

A packer’s diameter affects injection pressure capacity and fit within drilled holes. Common sizes include 5/8” (16mm), 1/2” (13mm), 3/8” (10mm), and 1/4” (6mm). Larger diameters are generally more resistant to blow-outs and provide a stronger grip, especially for high-pressure and rock applications.

Length

Longer packers, ranging from 4″ to 6″, are ideal for deteriorated concrete or deep injections. They enable secure embedding within the substrate, minimizing the risk of spalling and bridging gaps in the structure.

Valve Placement

- Top-Mounted Valves: Zerk and button-head valves allow for observing grout travel during injection. Button-head valves offer a stronger connection with less leakage.

- Bottom-Mounted Valves: Positioned on the stem, these valves allow the packer’s head to be removed after injection, keeping the seal intact and facilitating patching.

Conclusion

The 1/2″ (13mm) diameter mechanical injection packer is often a reliable starting point for most projects. Steel packers are ideal for very high injection pressures, though economical considerations may favor alternatives like aluminum, brass, or zinc for a variation of scenarios including jobsite conditions and budget.

Larger diameter injection packer can reduce blow-out risks, while longer packers are recommended for angled drilling and degraded substrates.

High-flow applications at lower pressures may benefit from the 5/8″ button-head packers, while the 3/8″ Hammer-In packers could be suited to low-pressure work in high-quality concrete.

SealBoss offers a diverse range of packers and ports, including surface ports with zerk fittings for smaller epoxy and polyurethane jobs and injection screws for cold joint applications. Ensuring a secure fit and selecting the appropriate packer type is crucial for technician safety and successful injection results.

Injection Packers for Crack, Water Stop and Leak Sealing Injections

SealBoss injection packers connect the injection equipment (applicator and injection pump) with the structural substrate to serve as the port of entry – or filler neck – for a large variety of injection resins and chemical grouts into concrete mediums.

Our Packers are made from a various metals including steel, brass, zinc, aluminum / aluminium or plastic. Packers are typically equipped with either a zerk fitting or button head fitting for easy and secure connection to the applicator. The button head type offers the most secure connection in overhead, high pressure and high volume appplications.

Conditions of the jobsite, environment and material determine the type, material, and build of packer, in order to achieve the best injection results. SealBoss provides a very large selection of injection packers to meet all professional needs.

Injection Packers – Installation Types

Based on injection requirements and injection products to be used, we distinguish between borehole packers and surface mount packers, also known as surface ports.

Cylinder shaped, borehole type injection packers are typically used for high pressure injection with polyurethane bases, water stop and leak-seal resins and injection foams.

Borehole style packers work very well in wet and otherwise demanding environments, such as deteriorating concrete substrates.

We further differentiate between mechanical packers with a tighten-down and screw-in mechanism, and hammer-in technique packers.

The seal of the aforementioned packers is achieved by friction between the packer body in the drill hole and the surrounding substrate.

Surface mounted ports are mostly used for structural epoxy injection where a non-destructive injection process – no drill holes allowed procedure – is specified.

Surface mounted packers or surface ports are glued to the surface of the substrate and rely on the bond strength of the adhesive, such as SealBoss 4500 epoxy paste adhesive. Surface port placement is best performed on a dry substrate and can be difficult in wet environments with active water leaks.

Preparatory work

Step1 – Structure / Substrate / Product Analysis

- Condition of structure, environment and climate

- Chemical rout / resin specified

- Injection pressures expected (high pressure vs low pressure)

Step 2 – Packer Choice

- Select suitable injection packers.

Please consult with your SealBoss Technical Rep.

Installation

Installation procedures depend on the conditions found at the jobsite. SealBoss provides detailed information online and in printed publications. Please contact your technical rep.

The size of the drill holes equals the stated diameter of the mechanical packers and hammer-in packers; the borehole depth varies according to the conditions and requirements.

Drill holes are typically made at an angle of approx. 45° depending on the wall thickness and other conditions. All drill dust and debris must be removed from the boreholes.

Final work

- Remove or knock-off the mechanical packers / hammer-in ports / surface packers as specified

- Patch the drill holes with suitable mortar

Related Links