Choosing Your Products for Water Stop & Leak Sealing Injection

Choosing the product with the correct properties for the job is the first step to a successful and long lasting leak seal and crack injection application. Material with the appropriate physical properties simplifies the application and provides for long term durability.

We differentiate between hydrophilic and hydrophobic products which vary in their physical properties, such as viscosity, expansion rate, reaction time, flexibility, density and hardness.

Hydrophobic Chemical Grouts

SealBoss 1510/1570/1570LV/1500 polyurethane injection grouts form a group of hydroactive, hydrophobic injection resins, sharing basic physical properties. Water/moisture initiates the reaction only, but the cured product is insensitive to moisture and of a constant volume. Since water is not a component of the foam structure, the cured material is essentially not effected by water or dryness and does not shrink or swell. Products are not effected by freeze/thaw and wet/dry cycles.

SealBoss 1640 Foam & SealBoss 1403 PUR Resin are hydrophobic products that do not require water to react.

Hydrophilic Chemical Grouts

SealBoss FlexGel & SealBoss 2400 Acrylate (Acrylic) Gel are hydrophilic products. Water/moisture initiates reaction and the product is capable of absorbing and incorporating water post cure, thereby swelling and forming a waterproofing flexible gel or foam. Hydrophilic products are recommended for applications in permanently moist environments, curtain/bladder injection, and capillary injection.

Viscosity

SealBoss 1510/1570/1500 Water Stop Foams & Flexgel are of low viscosity for good penetration into concrete cracks and joints. For hairline cracks, capillary fissures and tight cold joints we provide super low viscosity products such as SealBoss 1570LV Water Stop Foam, SealBoss 1403 PUR Resin, SealBoss 2400 Acrylate (Acrylic) Gel.

Accelerator Adjustable Hydro Active

Expansion & Reaction Time

The reaction times and expansion rates of SealBoss 1510/1570/1570LV Water Stop Foams are adjustable by adding a specific amount of SealBoss accelerator. The gel times of SealBoss 1403 PUR Resin & SealBoss 2400 Acrylate (Acrylic) Gel are also adjustable.

The reaction time and expansion rate of a foam determine the water stop and penetration properties of the product.

Faster reaction times and expansion benefit water cut-off properties, slower reaction times enhance product penetration in the substrate.

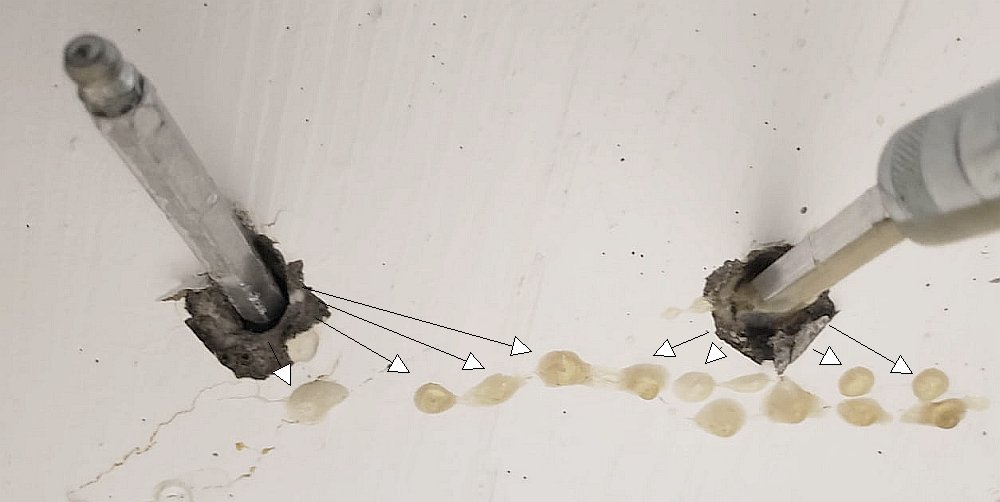

Water-reactive polyurethane grouts expand on contact with water by the resulting CO2 gas. The foam expansion creates a compression seal which supports the sealing properties of the injection grout.

Rapid expansion helps to cut-off high-volume active water leaks and benefits curtain/bladder grouting. The expansion rate of a foam determines material consumption, cell structure and density of the cured product. It should be considered that expanding foams can create a significant amount of pressures.

Our best-selling, industry standard SealBoss 1510 Water Stop Foam, can rapidly expand between 5 to 50 times (50X) of free rise product volume when catalyzed accordingly.

Flexibility & Density

For most injections in joints, cracks and some curtain/bladder wall grouting that do not experience much movement, semi flexible standard products with high expansion rates and higher compressive strengths such as SealBoss 1510 Water Stop Foam, SealBoss 1500 2-Component Water Stop Foam are used.

Structures exposed to thermal expansion and contraction or dynamic loading resulting in increased movement may require a flexible formulation grout such as SealBoss 1570/1570LV Water Stop Foam, SealBoss 1403 PUR Resin or SealBoss Flexgel. SealBoss 1403 PUR Resin is also recommended as follow-up and final seal injection in critical foam injection areas.

Good product density, complete penetration and adequate product consumption make for a successful leak seal injection. Injection pressures must be high enough to provide for good material travel, proper penetration and density.

We recommended to always monitor injection pressures and material flow closely. When done correctly, the high density injection material will form a compression seal and provide for a or a long lasting application.