Sealing Pipe Penetrations in Foundation Wall

Sealing Pipe Penetrations in Foundation Wall

Football Team Field House

SealBoss PUR Grout Injection

Sealing Pipe Penetrations in Foundation Wall with Chemical Grout Injection

Location: Sam Houston State University – Huntsville, TX

Project Spotlight: Sam Houston State University Football Field House Renovation

Background:

Sam Houston State University embarked on an ambitious renovation project for its football team’s Field House and Locker Room.

Scope of Work:

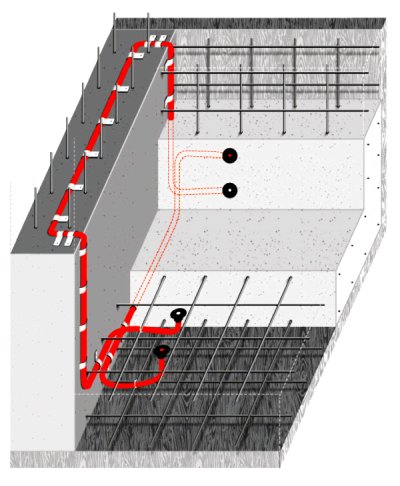

The renovation involved the addition of masonry walls and the sealing of old Pipe Penetrations. Contractors were instructed to remove the existing pipe penetrations, seal them with a grout patch, and subsequently drill a ½” hole through the patch. An injection was then carried out behind the grout patch, ensuring a watertight seal, as outlined by the project engineer.

Expertise in Action:

The project contractor enlisted SealBoss to provide hands-on technical guidance for the specified injection process.

Additional Training:

Beyond the specified injection process, the contractor was also trained in alternative repair techniques. This included using SwellCaulk and Oakum to effectively seal off the pipe penetrations.

This collaborative approach and training ensured the project’s success while also expanding the contractor’s repertoire of repair methods.

Sealing Pipe Penetrations in Foundation Wall – Specified Repair Procedure

After ensuring the grout patch was fully set, the contractor drilled a ½” hole directly through its center. Debris from the hole was carefully vacuumed out, and the hole was subsequently flushed using a specially modified water bottle, ensuring a clean, pressured stream. Once thoroughly cleaned, the ½” SealBoss Evolution 13-100AL injection packer was fitted in place.

Utilizing the SealBoss P2002 pump, the SealBoss 1510 Water Stop Foam System was pressure-injected into the void behind the grout patch. This process guaranteed an air and watertight seal, preventing any water seepage through the patch.

Chemical Grouting Products Used

- Injection Resin: SealBoss 1510 w/ 15x Accelerator

- Injection Packers: 1/2” Aluminum Packers

- High Pressure Pump: P2002 Single Component Injection Pump

- Cleaning Materials: Xylene, R70 Pump Flush, rags, bucket

- Additional Tools: 18” x 1/2″ drill bit — 3/8” Crescent Wrench — Dead Blow Hammer

- Hammer Drill — Access 110v Power — Vacuum

Choosing the Right Product

No one-size-fits-all resin exists. To ensure the highest quality results and adherence to specified standards, the right resin choice is pivotal.

SealBoss offers a suite of chemical grouting injection systems tailored for various challenges encountered in geotechnical projects, tunneling, underground waterproofing, and broad-spectrum civil engineering tasks.

Find additional chemical grouting information here:

- Erosion Control / Permeation Grouting with Podcast

- Acrylate Tunnel Grouting with Videos

- Dam Spillway Grouting

Sealing Pipe Penetrations in Foundation Wall? Call Your SealBoss Repair Specialist

If you have any questions on chemical injection grouting or any related applications, please contact our team of qualified SealBoss grouting repair representatives to schedule an on site consultation & full systems training. Call us at 714-662-4445.