Hot Shot Foam Injection Cartridges

Hot Shot

Foam Injection Cartridges

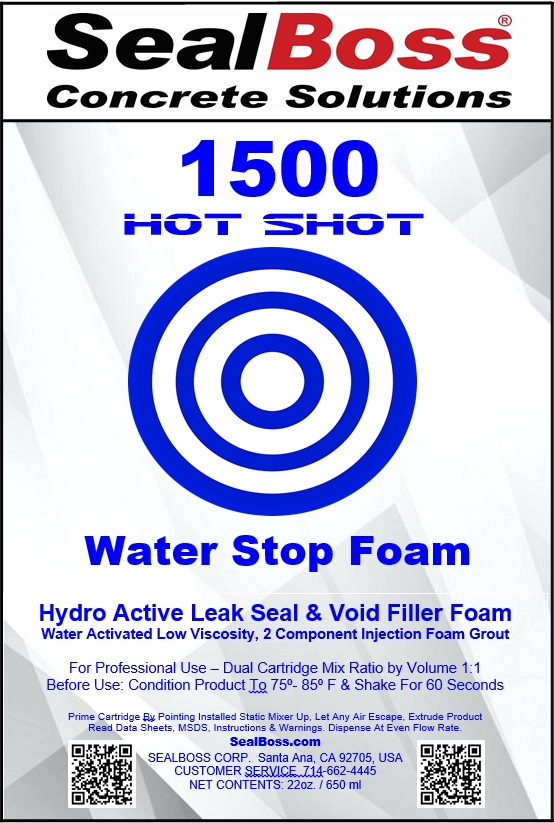

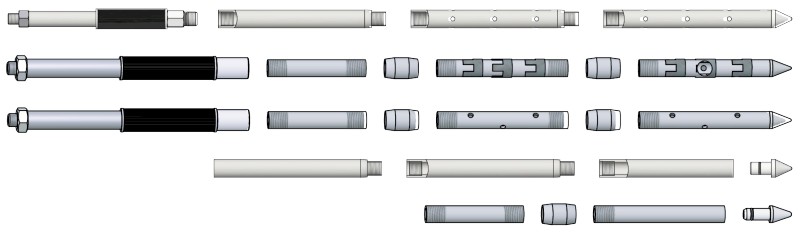

- SealBoss 1500 Hot Shot is a water activated, hydro active, semi flexible foam injection resin, designed to shut down active water leaks quickly – Bigger is better, we give you 22 oz. per cartridge!

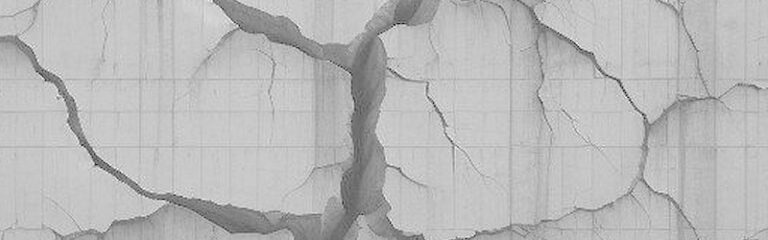

- Concrete Crack & Pipe Penetration Leak Repair

- Gushing Water Leak Stop

- Semi-Rigid Properties Tolerate Movement

Choose Your Hot Shot

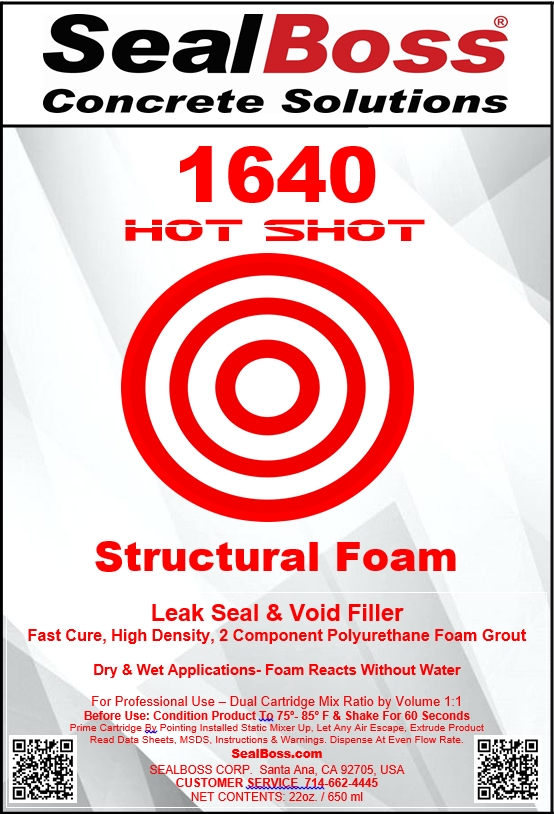

- SealBoss 1640 Hot Shot is a dry reactive structural foam system and void filler for use in dry and wet condition – Bigger is better, we give you 22 oz. per cartridge!

- Wet and Dry Applications

- Void Fill Applications

- Under Slab Fill Applications

Hot Shot Applicators

Water Stop & Leak-Seal

Water Plug & Void Fill

Two Distinctly Different Foams

in Convenient Hot Shot Cartridges

Our Hot Shot Cartridge System is perfect for those jobs that don’t require a pump set up

Master the art of water stop and leak sealing, as well as water plug and void filling tasks with the convenient SealBoss Hot Shot Cartridges. The cartridges offer two unique foam solutions, perfect for small-scale repair projects that don’t necessitate the use of a complex pump setup.

Harness the power of two unique foam solutions, packed conveniently in our Hot Shot Cartridges, for all your small-scale repair jobs that don’t necessitate a cumbersome pump setup. All you need to kickstart your repair work is a hammer drill, drill bits, your chosen Hot Shot Cartridges, and a cartridge gun.

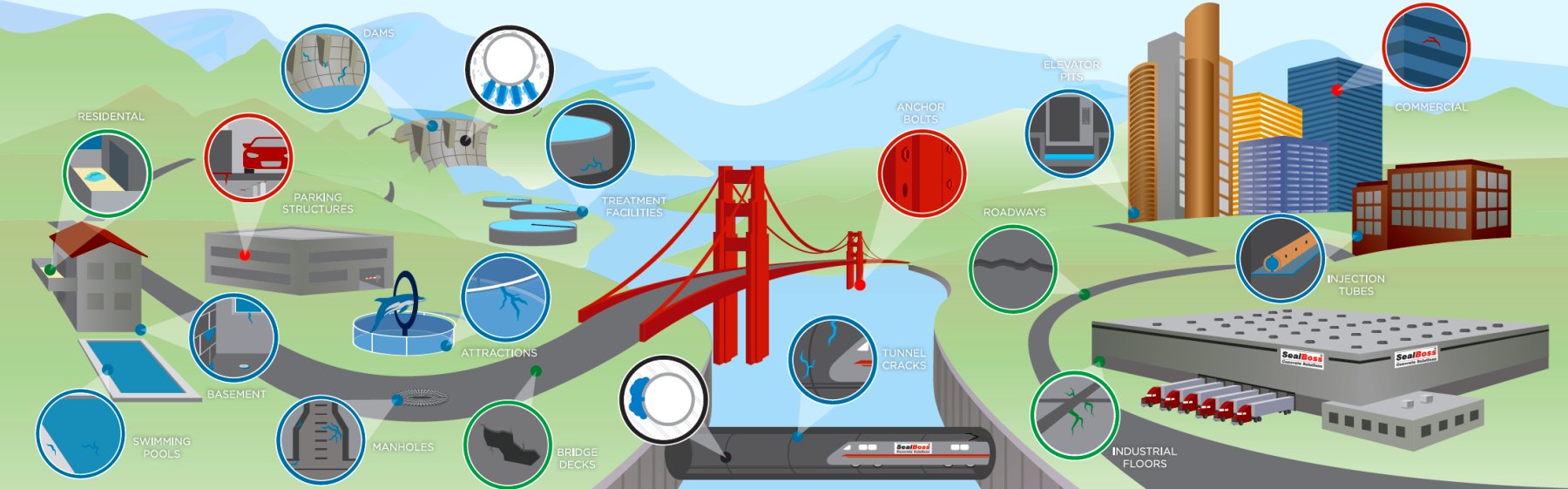

From walls, manholes, box culverts, floors, to storm and sewer pipes, SealBoss Hot Shot Cartridges serve a myriad of applications. The ease of use of these 22oz cartridges makes them a popular choice among professionals and DIY enthusiasts alike.

Applying the SealBoss Hot Shot Cartridges is as easy as following these steps:

- Drill a hole through the substrate

- Position the injection tip in the drilled hole and pump the SealBoss Hot Shot product

- Alternatively, you can use the Low Pressure Zerk Injection Packer System Adapter

The Power of Simplicity – Foam Injection “Hot Shot” Cartridges

In the concrete repair and waterproofing industry, innovation plays a pivotal role in enhancing results and processes. Traditional approaches, while effective, often demand substantial time, expensive equipment and labor, which might not always be adequate and necessary for the job on hand.

Addressing these concerns, SealBoss introduces their professioanl grade foam injection Hot Shot Cartridges, reshaping the way we confront these challenges.

These Hot Shot cartridges serve as a simplified tool to apply the same high grade products, offering an efficient, user-friendly, and economic solution to a variety of repair tasks. From addressing leaks in a residential basement to mending cracks and filling voids in a commercial building’s foundation, Hot Shot cartridges simplify and accelerate the repair process.

Unmatched Efficiency

One of the prominent advantages of SealBoss’s “Hot Shot” cartridges is their remarkable time saving efficiency. Their innovative design and size, facilitates quick and effective foam injection tasks, reducing the time spent compared to traditional methods.

This efficiency is largely due to the cartridges being pre-filled with high-grade polyurethane resin that rapidly reacts and expands — no measuring and mixing needed — cutting down the material preparation time and overall process duration.

User-Centric Design

SealBoss’s Hot Shot cartridges stand out for their remarkable efficiency. Their innovative design and pre-filled high-grade polyurethane resin facilitate quick and effective foam injection tasks, reducing time spent compared to traditional methods.

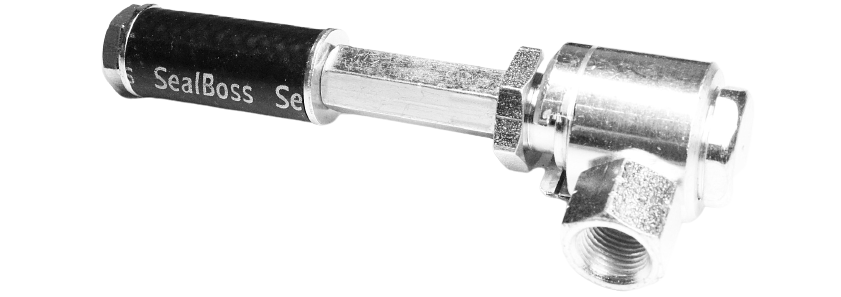

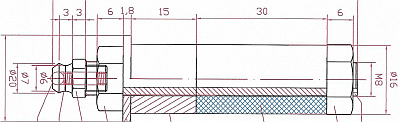

The user-centric design of the Hot Shot cartridges ensures easy installation and operation, even for individuals with limited technical expertise. By eliminating the need for large, complex pumping systems, these cartridges streamline the injection process and make it accessible for even DIY enthusiasts to manage small-scale repair projects. SealBoss’s Hot Shot cartridges are also compatible with the SealBoss Steel Injection Packer Adapter for added convenience.

HOT SHOTS can be used with SealBoss’s Steel Injection Packer Adapter.

Conclusion

Whether you’re an experienced professional seeking to streamline your processes or a homeowner undertaking a repair project, SealBoss’s “Hot Shot” cartridges offer a solution that maximizes time, minimizes effort, and ensures reliable, lasting results.

For all your smaller jobs and projects, discover the innovation and efficiency offered by SealBoss’s Hot Shot cartridge system.

Opt for SealBoss Cartridges for all your smaller tasks and projects.