SealBoss Cartridge System

The SealBoss Cartridge System presents a handy alternative for smaller tasks where extensive amounts of product are unnecessary, and the deployment of heavy-duty equipment and its related costs is avoidable. The cartridges are user-friendly, neat, and transportable, eradicating complicated mixing processes and minimizing cleanup.

The system operates smoothly with budget-friendly handheld tools, airguns, and battery-powered dispensers. The quality and testing of SealBoss cartridge product formulas are as stringent as our standard product ranges.

HOT SHOT Cartridge Range – Hydro Active and Dry Reactive Polyurethane Foams

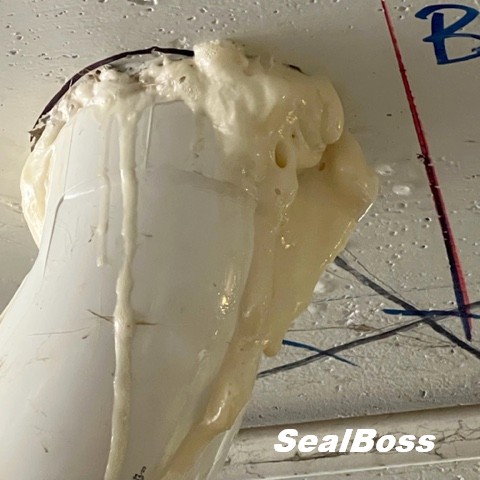

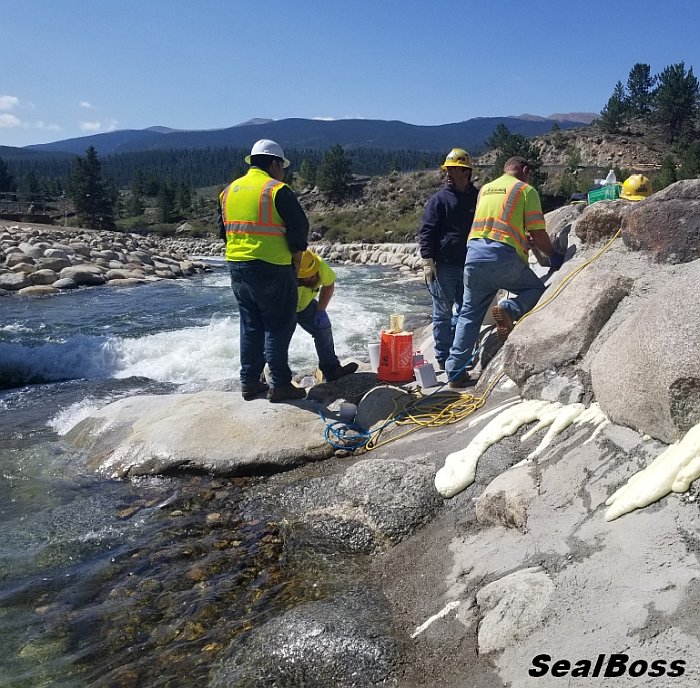

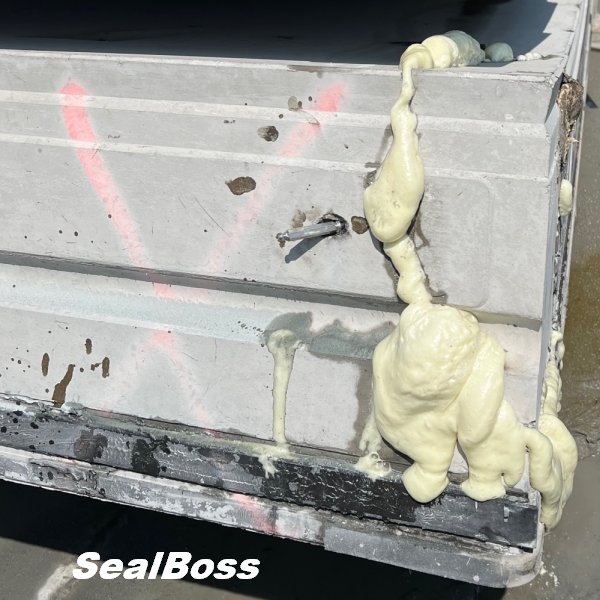

SealBoss 1500 HOT SHOT is a water-activated, dual-component polyurethane foam that swiftly expands upon water interaction. It is a prime choice for leak sealing and void filling applications. This premium dual-component formula excels in a cartridge system and produces a uniform foam expansion vital for exceptional water stoppage and waterproofing properties.

SealBoss 1640 HOT SHOT is a high strength, dry-reactive, two component polyurethane foam that offers a structural component to fill, plug and stabilize voids. The product reacts quickly and independently of water.

Green Cartridge Range – Polyurethane and Polyurea Solutions for Floor Joint Fill, Crack, and Road Repairs

SealBoss 6500 QuickFix Polyurea Joint Filler is a superior joint and crack filler for concrete in time-sensitive scenarios. It performs well in various temperature conditions as it hardens quickly in ambient temperatures ranging from -20F to 130F. The tack-free time is a mere 5 to 15 minutes, and a quick cure time allows the job site to reopen for vehicular and pedestrian traffic just one hour after the application (note that lower ambient temperatures will prolong the cure time).

SealBoss 6060 Spall Repair and Concrete Crack Mender is devised to repair concrete floor cracks and spalls to a smooth finish swiftly (lower ambient temperatures will increase the cure time). The product has extremely low viscosity allowing for deep penetration. When mixed with aggregate, SealBoss 6060 can be utilized for speedy road crack and concrete spall repairs.

Red Cartridge Range – Epoxy Resin System for Structural Repairs

SealBoss 4040 LV Epoxy is a low-viscosity, 100% solids, dual-component, high-modulus, moisture tolerant, high-strength epoxy injection resin adhesive. It has a low odor, making it a pleasant work companion.

SealBoss 4050 SLV Epoxy is a super low-viscosity, 100% solids, high-modulus, dual-component, moisture-tolerant, high-strength epoxy injection resin adhesive, devised for use in very fine cracks and fissures.

SealBoss 4500 Epoxy Paste is a 100% solids, dual-component epoxy paste adhesive designed for surface repairs, crack preparation for resin injection, and as a bonding agent for SealBoss Plastic Surface Mount Ports. It sets quickly and has a low odor.

In conclusion, the SealBoss Cartridge System embodies a seamless solution for small-scale applications, enabling easy use and cleanup while reducing the necessity for bulky equipment. Its diverse product range, from the HOT SHOT cartridge series for rapid foam expansion and water sealing, the Green Cartridge line dedicated to quick concrete floor, joint fill, and road repairs, to the Red Cartridge range focusing on structural epoxy repairs, ensures a versatile solution to a wide array of construction needs. Crafted for performance, affordability, and simplicity, SealBoss provides an essential toolset for professionals, offering superior products that deliver high quality and effectiveness, cementing its position as a trusted partner in the construction repair industry.