Seal Leaks with Oakum

Seal Leaks with Oakum

What is Oakum Soakum?

For Best Results, Soak the Oakum.

– Oakum Soakum –

The Benefits of using the Oakum Seal Method

Seal Oakum is an untreated, strong, dry and oil free jute based fiber capable of absorbing copious amounts of SealBoss chemical grouts. Resin impregnated Seal Oakum reacts with water and expands to form a dense and flexible seal. It offers major benefits for many leak sealing jobs by keeping injection resin in place and prevent it from escaping and leaking during the injection process and prior to cure. With soaked oakum you can create a physical barrier to prevent active water infiltration in larger openings, irregular cracks and joints.

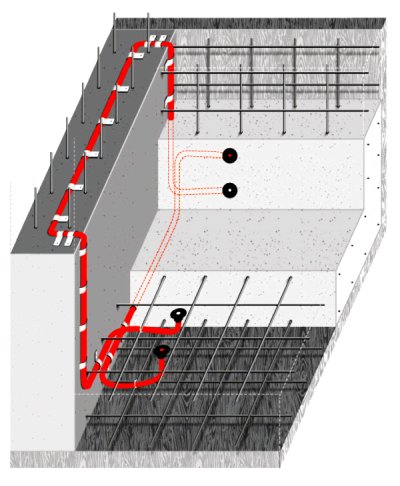

Oakum is mainly used as a carrier medium for hydro active foam resins for use in wide openings to seal leaks. It is used to slow down massive water flow to permit the injection foam to cure. For this application Seal Oakum is soaked in SealBoss foam grout leak-seal resin and the saturated product packed into actively leaking cracks and joints as a compression seal. ‘Oakum Soakum’ is an industry known term for the technique. Prior to use inspect area for loose concrete and remove any contamination to prepare for insertion of the fiber into the desired location.

Can I use un-soaked, dry Seal Oakum?

Seal Oakum also works well dry when driven into cracks as a temporary seal to allow injected resin time to cure without washing out.

Seal Oakum is cut to length and sold in ready-to-use sets

How to and Where to use Seal Oakum

- For Use With SealBoss Hydro Active PU Water Stop Foam Injection Grouts – Oakum Soakum Technique

- Create Joint Gaskets or Use in Combination with Gaskets in Sewer & Storm Drain Lines, Ducts

- Wastewater Treatment Plants

- Reservoirs & Water Tanks

- Service Manholes

- Tunnels & Underground Cable Trenches

- Pipe Penetrations,

- SealBoss Seal Pipe Kit

How to Seal Gushing Leaks and Wide Cracks with Seal Oakum

- Use gloves and protective gear during the oakum soakum application process

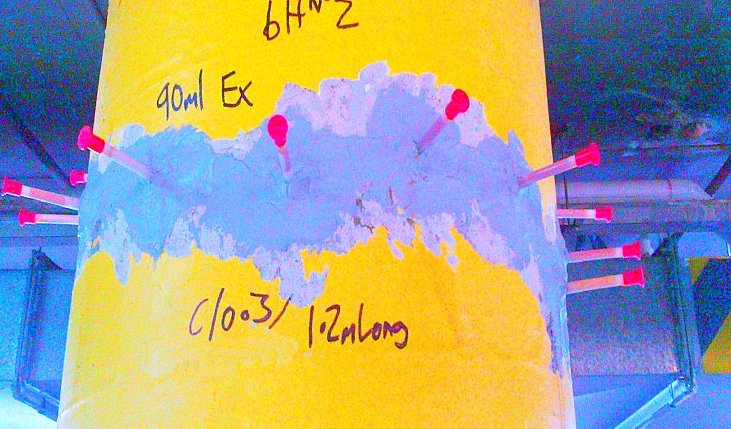

- It is recommended to drill packer holes and set packers prior to oakum use.

- One, or several relief holes may divert water pressure during the oakum placement

- Clean the surfaces to which the oakum will be applied

- Place oakum in a container and saturate with SealBoss Water Stop Foam

- Remove excess resin from the oakum

- For minor leaks or dry cracks or joints dip the resin soaked oakum into a pail of water to begin the reaction process and expansion

- Pack oakum into the joint or crack with a large screwdriver or any tool suitable for the task

- In cases of severe water pressure you may want to use a wooden board or other suitable product to mechanically support the applied oakum from being pushed out

- Injection should be performed through preinstalled packers. If advised, a SealBoss Injection Needle may be used to inject grout directly through the oakum.

Sealing Pipe Penetrations with Seal Oakum

To seal pipe penetrations, resin saturated oakum can be sprayed with water or dropped into a pail of water to start the activation process. The reactive oakum is now packed into joints and around leaky pipe penetrations where it creates a watertight seal between the outside of the pipe and the wall of the structure.

Used dry, oakum fibers can be packed into wider cracks and joints to retain injected SealBoss polyurethane resin.

Installation Guidelines

Submerge SealBoss 1500 Seal Oakum into activated foam resin. When removing from container, wipe off excess material. If necessary, wet joints or voids with water to prime surface for saturated SealBoss® 1500 Seal Oakum.

To seal minor leaks, dip saturated SealBoss Seal Oakum into water to start reaction.

Place saturated SealBoss Seal Oakum in the joint or void. You may also spray saturated oakum surface with water to speed up the cure process. Cut excess product from substrate surface after cure.