Polymer Soil Stabilization

The world of civil engineering is no stranger to the trials posed by unstable soils. From erosion and improper compaction to the effects of freeze-thaw cycles and the decomposition of organic materials, these factors can seriously compromise the structural integrity of any project. The result? Soils that shift and refuse to stay anchored, posing significant risks to structures and their foundations. For geotechnical engineers, the challenge has always been to find innovative solutions that not only reinforce the ground but also restore its ability to bear loads effectively.

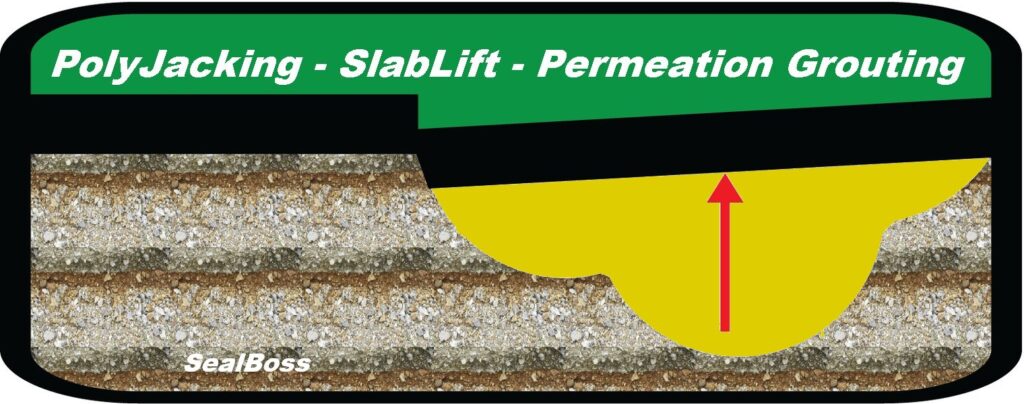

Polymer soil stabilization, a cutting-edge soil injection system turn the tables on unstable terrains. Soils that were loose and unmanageable are transformed into cohesive, fortified masses. How it works: Polymeric resins, with their unique properties, seep into porous soils, filling gaps and compacting even the most stubborn terrains. This not only halts the processes of subsidence and erosion but also prevents the migration of fine particles. SealBoss offers polymer soil stabilization solutions that meet the highest industry standards.

Polymer Soil Stabilization

A Modern Solution to Age-Old Challenges

The world of civil engineering is no stranger to the trials posed by unstable soils. From erosion and improper compaction to the effects of freeze-thaw cycles and the decomposition of organic materials, these factors can seriously compromise the structural integrity of any project. The result? Soils that shift and refuse to stay anchored, posing significant risks to structures and their foundations. For geotechnical engineers, the challenge has always been to find innovative solutions that not only reinforce the ground but also restore its ability to bear loads effectively.

Polymer soil stabilization, a cutting-edge soil injection system turn the tables on unstable terrains. Soils that were once loose and unmanageable are transformed into cohesive, fortified masses. How it works: Polymeric resins, with their unique properties, seep into porous soils, filling gaps and compacting even the most stubborn terrains. This not only halts the processes of subsidence and erosion but also prevents the migration of fine particles. SealBoss offers polymer soil stabilization solutions that meet the highest industry standards.

The Mechanics Behind Polymer Foam Stabilization:

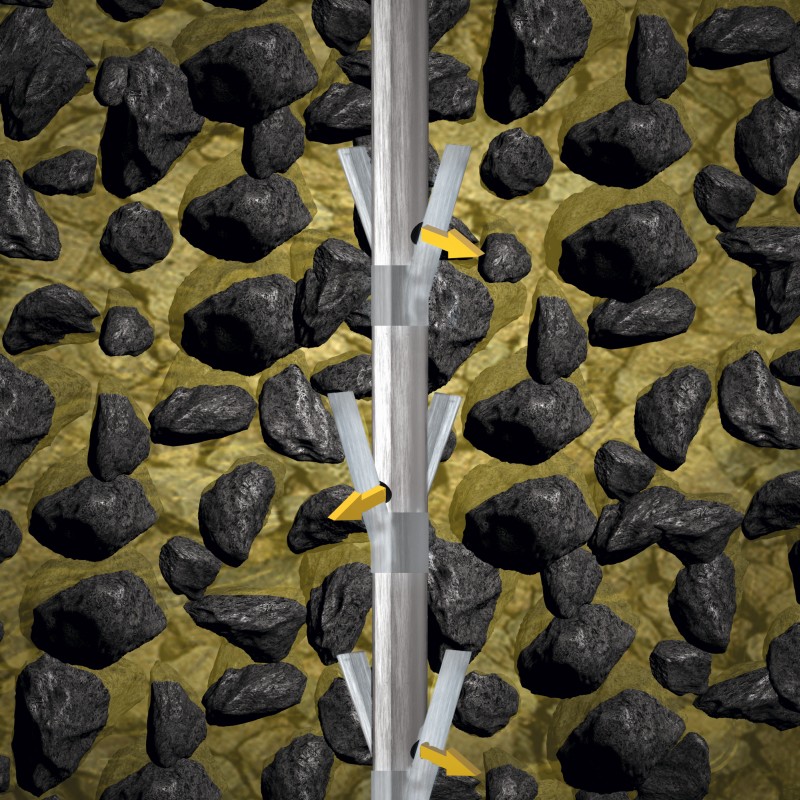

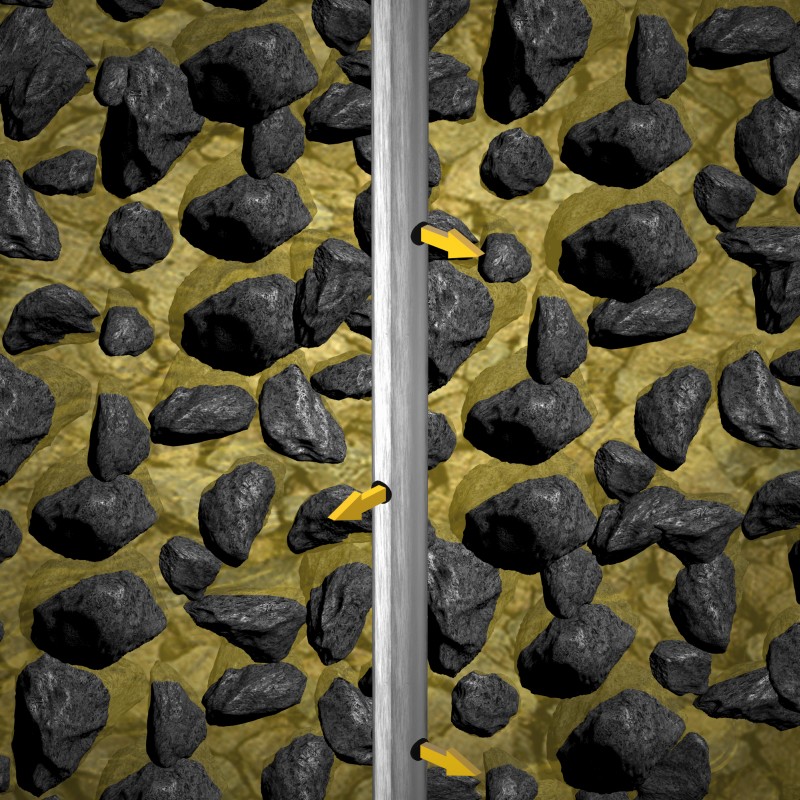

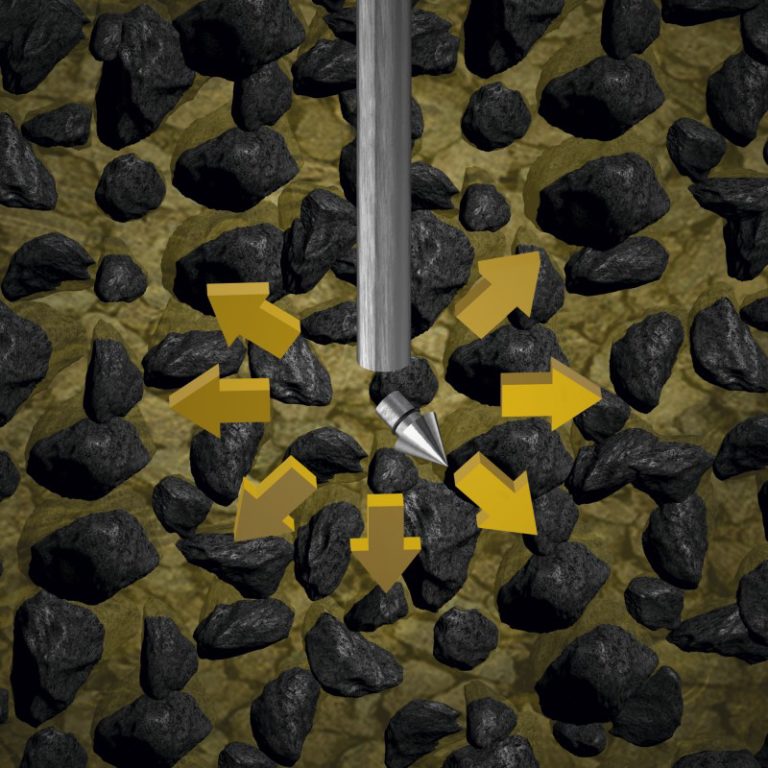

- Permeation and Matrix Formation: The polymers permeate through loose sediments, soils, and sands, binding them together into a cohesive matrix forming a solid structure.

- Erosion Control and Water Displacement: By displacing water from areas affected by erosion, they prevent further deterioration of the soil.

- Void Filling and Void Management: Polymers effectively fill spaces left by decomposed organic matter or resulting from inadequate soil compaction.

- Strengthening and Adhesion: Their unique ability to adhere to soil particles ensures the creation of a fortified substrate.

Performance Highlights of Polymer Soil Stabilization:

Polymer soil and sand stabilization efficiently treats unstable soils and sands in-situ, eliminating the need for excavation. These polymers compact treat loose or unstable soils, enhancing their structural strength and offering long-term stabilization. By permeating loose sediments, displacing water from eroded areas, and filling voids, they create a fortified soil matrix that resists erosion and subsidence. Additionally, NSF/ANSI/CAN 61 certification of the specific polymer foam resins ensures safety for potable water contact, emphasizing both their efficacy and environmental commitment. Geotechnical Engineers, kindly reach out to our technical team for detailed specification guidance and assistance.

Related Links:

Stainless Steel Injection Needles

SealBoss Injection Needle for specialty grouting applications and product delivery into soil substrate, through small holes, Oakum Soakum Injection Technique and more. Suitable for PU, EP, Polyacrylate, and Silicate grouts.

Slab Lifting, Soil Compaction, Permeation, and Consolidation Injection Systems

Slab Lifting, Soil Compaction, Permeation, and Consolidation Injection Systems

Injection of concrete parking structure in St. Louis, Missouri using the SealBoss Water Stop System

Injection of concrete parking structure in St. Louis, Missouri using the SealBoss Water Stop System