Aquarium Leak Sealing Repair

Marine Aquarium Repair & Training

NSF/ANSI 61 Certified Water Stop

Protect Aquatic Life

The Importance of NSF Approval for Aquarium Leak Sealing Repair

NSF (National Sanitation Foundation) drinking water contact certification is crucial for polyurethane grouts used in aquariums. NSF/ANSI 61-5 standards specifically address materials in contact with drinking water, requiring rigorous safety testing and quality assessments.

Manufacturers of NSF-approved products undergo thorough testing and facility inspections to ensure their products are safe when in contact with drinking water. This certification is vital for public aquariums, as it ensures the safety and quality of the water, protecting aquatic life and the well-being of marine organisms.

Aquarium Leak Repair System

SealBoss Leak Repair System Delivery to Texas and Field Service

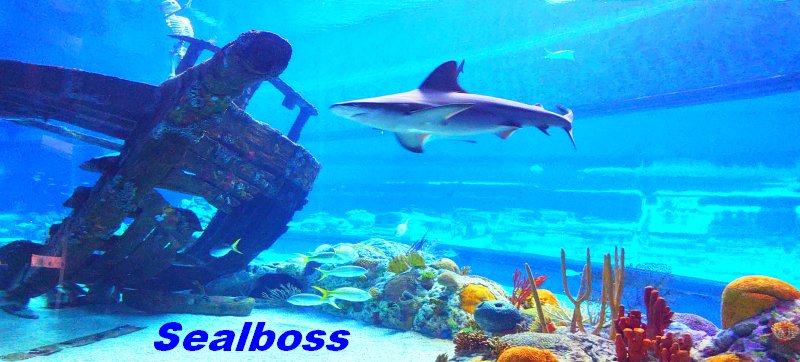

A 68 foot-long acrylic window- the longest in North America – provides a clear view of the marine life. For those wishing to spend time in an extraordinary place, a promising unforgettable experience awaits.

The idea for the Texas State Aquarium was conceptualized by its founders early on to focus on the species in the Gulf of Mexico and the Caribbean Sea.

The Caribbean Journey doubles the size of the aquarium and provides homes to an exciting collection of sea and land creatures.

It is here that you can break into the mesmerizing secrets of the underwater and jungle world. Gather your courage and dive below the waves to get a closer look, but keep your eyes open and your wits about you, for you’re now in the home territory of the reef shark.

Aquarium Leak Sealing Repair Challenges

Product Compatibility and Durability

Public aquariums, rely heavily on the compatibility of materials used in their construction. maintenance, and repair. Polyurethane injection grouts, a popular choice for sealing water leaks, must harmonize with a variety of materials like acrylic, glass, and specialized sealants to maintain the integrity of these exhibits.

The relationship between the chemical grouts and existing construction materials is crucial for sustaining the meticulously crafted habitats. Skilled and well trained contractors play a vital role in this process, applying grouts with precision to protect the structures and achieve the set goals of the needed repairs.

The durability of polyurethane grout leak sealing materials is a critical factor for aquarium managers, influencing maintenance planning and resource allocation. These grouts offer long-lasting seals, reducing maintenance efforts and costs, and allowing for extended maintenance cycles. Product quality, ease of application and equipment reliabilty minimize exhibit downtime, important factors for public aquariums where visitor engagement and revenue are at stake. Seal longevity and reliable repair methods are a strategic element in maintaining the sustainability and uninterrupted operation of public aquariums.

Enhancing Aquarium Maintenance with SealBoss Leak Repair Solutions

SealBoss Aquarium Leak Repair Systems, Training, and Support

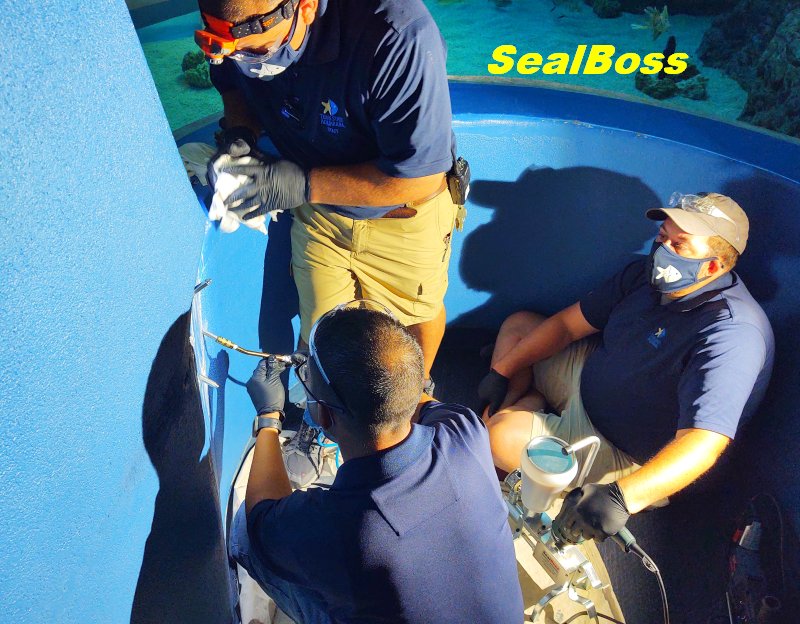

Recently, the SealBoss technical team made a significant impact at the State Aquarium in Corpus Christi by addressing persistent leaks in their large saltwater tanks. These leaks, which had previously eluded repair by other contractors, were successfully tackled by a SealBoss technician who provided hands-on training in leak-seal and water stop crack injection techniques.

Utilizing the NSF Drinking Water Contact Certified SealBoss Water Stop Foam and the P2002 Professional Injection Pump, the SealBoss expert equipped the aquarium’s maintenance team with the skills and knowledge needed for effective, ongoing leak management. This training ensures that the team can handle future leak-seal challenges confidently and efficiently.

SealBoss systems are designed not just for one-time fixes but for empowering maintenance crews with the tools and techniques for lasting leak prevention. The comprehensive range of SealBoss injection systems and Pro Kits offers professional-grade solutions, tailored to the unique needs of aquarium maintenance.

Identifying leaks in the aquarium is a straightforward process, thanks to the visible salt deposits that form from evaporated seawater. These deposits, a clear indicator of long-standing leaks, are especially noticeable in the State Aquarium due to its use of water from the Gulf of Mexico. The aquarium’s 6-inch thick acrylic glass and supporting concrete structures, prone to shrinkage and stress cracks over time, are typical areas where SealBoss training focused on.

The SealBoss 1, 2, 3, 45-Degree Injection Guideline was a key part of the training, teaching the team to effectively seal cracks and fissures. This technique, which involves staggered packer placement starting 6 inches from the crack center, proved highly effective under the specific conditions of the State Aquarium. The visible displacement of water and expulsion of chemical grout during the injection process was a clear sign of successful resin penetration, indicating a comprehensive seal of the cracks.

All areas were inspected for leaks and marked for injection. Some cold joints along the tank showed also signs of leaks, so preventative injections along cold/construction joints around the tank were advised.

In addition to addressing visible leaks, the SealBoss team advised preventative measures for potential leak sites, such as cold/construction joints around the tanks.

After the training session, the aquarium’s repair team was well-prepared to develop a comprehensive plan for managing both existing and potential future leaks.

SealBoss also offers innovative Cold Joint Seal Systems for use during the construction phase, which can prevent leaks from occurring in the first place. Products like SealBoss Swell-Caulk and the SealBoss Inject-Tube System are ideal for creating watertight “pour-in-place” cold joints.

For anyone facing challenges with cracks or water leaks, SealBoss waterstop systems offer a reliable solution. Our representatives are always available for consultation and support at 714-662-4445.

- Seawall Repair | Crack & Joint Leak Sealer | Soil Stabilization | Permeation Grouting

- Defective Concrete (Cracked or Honeycombed)

- Concrete Construction Joints & Cracks

- Brick Construction, Geo Formations

SealBoss ® 1510 NSF Water Stop Foam Advantages:

- Advanced NSF Formulation

- Up to 40+ Times Expansion

- SealBoss ® Product-Pump-Packer System Solution

- Unregulated For Transport

- Solvent Free MDI Technology

In Person and Video training is available upon request, contact SealBoss today to speak to your regional technical representative on our SealBoss full system solutions and offerings.

‘During on-site support and training, we create a positive learning environment to instill confidence and a level of comfort with the crew and applicators.

On-site training consists of an overview of SealBoss products and equipment and it’s features. This is followed by hands on training with actual injection of material until the applicator has gotten comfortable with the application techniques and nuances of the material used. Finally we focus on the correct cleaning procedure of the equipment.

From training new companies to new employees, SealBoss has continued to provide support to our users for 34 years and look forward to continuing this tradition in the years to come.

We won’t leave a jobsite till everyone is comfortable with the systems and can reteach the next person in line.

With a knowledgeable technical support team, we are here to help with any questions you may have’

The SealBoss Technical Team