Water Tank Injection

Water Tank Leak Seal Injection Training

Large Water Tank Injection Leak Repair with SealBoss 1510 Water Stop Foam

SealBoss offers full system solutions for water stop & leak repair with high pressure polyurethane injection

Introduction

Drinking water tanks are specifically constructed to maintain a sealed, water-tight environment; however, cracks and leaks in expansive concrete water storage structures, frequently detected during construction, can lead to numerous undesired outcomes. These may encompass significant water loss or water ingress contaminated by pollutants and germs, potential health risks, and structural damage to the tank.

Cracks and leaks in large concrete water tanks can lead to significant water loss or water ingress (pollution/germs), potential health risks, and structural damages. Repairing these issues in a timely and efficient manner is crucial for maintaining water quality and preventing further damage. In this article, we will discuss the process of repairing large concrete water tank cracks and leaks using the SealBoss Water Stop and Leak Seal Polyurethane Injection Foam, SealBoss Injection Packers, and SealBoss Professional Injection Pumps.

Ensuring Product Safety – Using NSF Certified Waterproofing Polyurethane Foam System

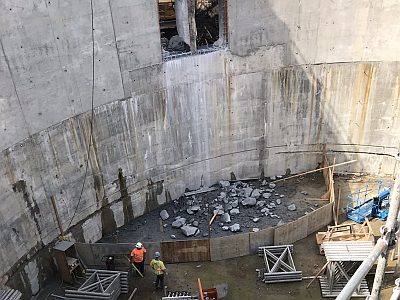

Western U.S. Regional Manager Chris Coderre instructs a construction team on urethane waterstop injection methods in Seattle, Washington

The NSF Drinking Water Contact Certified SealBoss 1510 Water Stop Foam and the SealBoss P2002 single component injection pump system with SealBoss 13-115S (½”) high pressure packers were used live in the training session at a large concrete water tank with active leaks.

The National Sanitation Foundation (NSF) enforces stringent standards to reduce the negative impact of products interacting with potable water.

Facilities like water treatment plants, water containment structures, and other related structures should be maintained and repaired using approved products that are deemed safe for contact with drinking water and won’t introduce contaminants that could cause health issues or regulatory concerns.The NSF is an independent organization that establishes public health standards and certification programs to safeguard food, water, and the environment. The American National Standards Institute (ANSI), a private non-profit entity, oversees the development of consensus standards for products, services, processes, and systems in the United States.

Adhering to NSF/ANSI/CAN 61 certification ensures that products comply with regulatory requirements for the U.S., Canada, and other countries adopting these standards.Products in contact with drinking water undergo NSF/ANSI/CAN 61 testing to confirm that contaminant levels remain below the maximum acceptable limits for safety. Rigorous testing is required for products to achieve NSF approval.

Inspecting the Water Tank

The first step in the water tank injection repair process is a thorough inspection of the tank to identify all cracks and leaks. This inspection should be performed by a trained professional, as they will have the experience and knowledge to detect even the most subtle signs of damage. Once the inspection is complete, the repair team can develop a plan for addressing the identified issues.

Preparing the Tank for Repair

Before beginning the water tank injection repair process, it is necessary to prepare the tank. First, drain the tank completely to ensure a safe and dry work environment. Then, clean the surface around the cracks, removing any debris. This step is crucial for the success of the repair, as a clean surface allows for optimal detection of crack development and subsequent injection packer placement.

Installing SealBoss Injection Packers

To inject the SealBoss Polyurethane Injection Foam into the cracks and leaks, Injection Packers must be installed. These packers serve as the entry points for the foam and ensure that it is directed precisely into the damaged areas. To install the packers, drill holes at regular intervals along the length of the crack, and then insert the packers into the holes. The number and spacing of the packers will depend on the size and severity of the cracks, as well as the specific requirements of the water tank injection repair project.

Preparing the SealBoss Polyurethane Injection Foam

The SealBoss Polyurethane Injection Foam is a single component accelerator adjusted system that requires proper mixing before use. Follow the manufacturer’s instructions for accelerator percentages, ensuring that the correct proportions are used to achieve the desired expansion rate and strength. Once the product is thoroughly mixed, the foam is ready for injection.

Injecting the SealBoss Polyurethane Water Stop Foam

With the SealBoss Professional Injection Pump, begin injecting the leak sealing foam into the installed packers. The foam will expand upon contact with moisture, filling the cracks and stopping the leaks. As the foam fills the cracks, it will create a strong and flexible seal, preventing further water infiltration.

Monitor the foam’s progress and continue injecting until the foam fills the entire crack and reaches the next injection port. Repeat this process for all injection ports, ensuring a complete and thorough repair. Re-inject packers two or three times until product refusal.

Post-Injection Cleanup

Once the SealBoss Polyurethane Injection Foam has fully cured, it is time to clean up. Remove the injection packers and any excess foam from the surface of the tank. Patch any remaining holes with a suitable patching material, to ensure a smooth and watertight finish.

Refilling and Testing the Water Tank

With the water tank injection repair complete, it is time to refill the tank and test for any remaining leaks. This step is crucial for confirming that the repair was successful and that the tank is now fully functional. Fill the tank gradually, monitoring the repaired areas for any signs of moisture or water seepage. If any leaks are detected, it may be necessary to repeat the repair process or consult a professional to address any underlying issues.

Ongoing Maintenance and Monitoring

After successfully completing the water tank injection repair, it is essential to implement a regular maintenance and monitoring schedule to prevent future issues. Inspect the tank periodically for signs of new cracks or leaks and address them promptly to avoid more extensive and costly repairs. Proper maintenance and monitoring will ensure the longevity of the water tank and the quality of the water it stores.

Conclusion

Using SealBoss Water Stop and Leak Seal Polyurethane Injection Foam, SealBoss Injection Packers, and SealBoss Professional Injection Pumps, large concrete water tank crack and leak repairs can be completed efficiently and effectively. This comprehensive water tank injection repair process provides a durable and flexible solution for sealing cracks and leaks, ensuring the structural integrity of the tank and the quality of the water it stores. By employing professional techniques, the contractor can successfully restore the water tank to optimal condition and prevent more extensive damage.

If you have any questions on crack injection waterstop procedures or any injection related applications, please contact our team of qualified SealBoss representatives to schedule an on site consultation & full injection systems training.