Vehicular Barrier Wall / Bumper Wall Repair

Epoxy Injection Systems

Vehicular Barrier Wall / Bumper Wall Crack Repair with Epoxy Injection Systems

Vehicular barrier walls, commonly referred to as bumper walls, are essential safety features in parking garages. Their primary role is to prevent vehicles from accidentally driving off the edges of ramps or elevated decks, ensuring the safety of both property and occupants. Maintaining the structural integrity and safety of parking structures is paramount.

However, over time these critical structures can suffer from cracks caused by continuous vehicle impacts, stress from structural shifts, weather exposure, and internal pressures from reinforcing cables.

The Damage: Cracked Vehicular Barriers

Cracks in vehicular barrier walls are more than a cosmetic issue; they can significantly weaken structural integrity. Untreated cracks can allow water and contaminants to penetrate the concrete, leading to corrosion of steel reinforcements, spalling concrete, and further weakening the structure. Early detection and prompt repair are crucial for maintaining safety standards and reducing long-term repair costs.

The Proven Solution: Epoxy Injection for Crack Repair

Epoxy injection presents itself as a proven, cost-effective method to repair cracks in structures. The technique involves the injection of a low-viscosity epoxy into the cracks. The injected epoxy fills the void and, once cured, can restore the structural integrity and strength of the concrete structure, warding off further damage.

The Tools: Epoxy Injection and Dispensing System

SealBoss P3003 Epoxy Injection Pump and SealBoss Surface Mounted Tri-Base Epoxy Injection Port System

Proven reliability and cost-effectiveness, the SealBoss P3003 Epoxy Injection Pump and SealBoss Surface Mount Tri-Base Ports exemplify a professional solution for epoxy pressure dispensing.

Ideal Applications of Epoxy Injection:

- Hairline shrinkage cracks

- Structural cracks due to movement or impact

- Vertical and horizontal structural surfaces

- Interior and exterior surfaces of barrier walls

Advantages of Epoxy Injection:

- Restores structural integrity and strength

- Waterproofs and seals cracks

- Prevents corrosion and further deterioration

- Cost-effective and minimally disruptive

Professional Tools: SealBoss P3003 Pump & Tri-Base Epoxy Injection Ports

The quality of crack repair depends heavily on the materials and equipment used. SealBoss provides a comprehensive solution tailored specifically for professional concrete crack repair applications.

Key Components:

- SealBoss P3003 Epoxy Injection Pump

A high-performance, professional-grade injection pump designed to deliver consistent and precise epoxy injections:

- Suitable for epoxy and polyurethane resins

- Standard mixing ratio of 2:1; convertible to 1:1 ratio

- Delivers pressures up to 5,000 psi

- Operated with a standard electric drill for portability and convenience

- SealBoss Surface Mounted Tri-Base Ports

These injection ports ensure optimal adhesion and precise epoxy resin delivery:

- Tri-base design with perforations for superior bonding

- Easy to mount directly over cracks using non-sag epoxy paste

- Provides an airtight and secure injection interface

Scope: Inject Structural Cracks on Exterior Vehicular Barrier Wall

Professional Epoxy Dispensing System:

SealBoss P3003 Epoxy Injection Pump & SealBoss Surface Mounted Tri-Base Ports

A successful epoxy injection process relies heavily on the right equipment. The SealBoss P3003 Epoxy Injection Pump and SealBoss Surface Mounted Tri-Base Ports are precisely designed to manage such repairs. Specifically, the P3003 pump is custom-designed with a 2:1 ratio feature in mind, or, if needed, a 1:1 ratio conversion, vital for most structural epoxies, providing optimal curing and strength characteristics.

Procedure: Repairing Cracks with Epoxy Injection

The epoxy injection process kicks off by preparing the crack for repair. Any loose concrete or debris within the crack is removed, the paint is grinded off, and the surface is cleaned thoroughly. For fine shrinkage cracks, the contractor chases the cracks out to allow for proper material travel during injection.

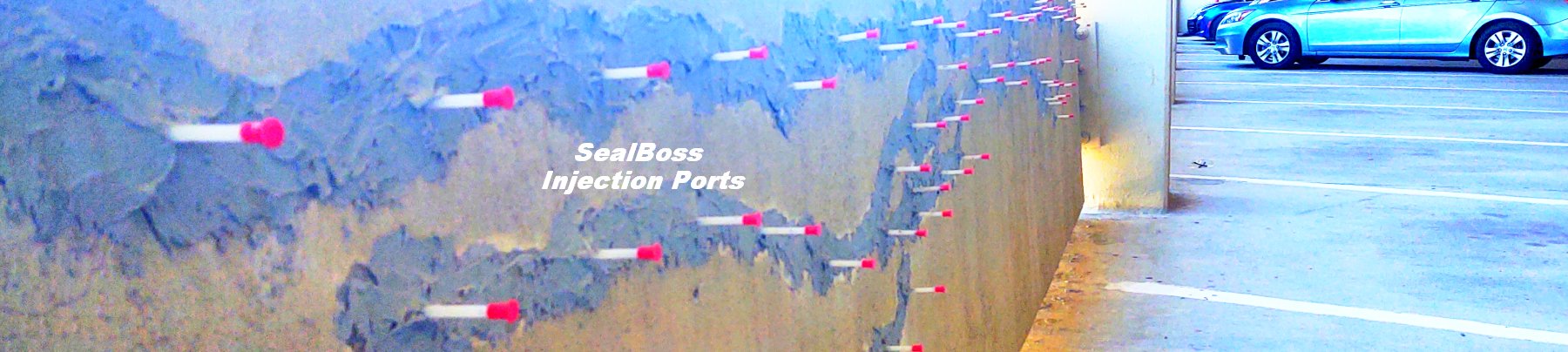

Connectors: SealBoss Tri-Base Ports

The SealBoss Surface Mounted Tri-Base Ports are strategically installed along the crack. Acting as a connector between the injection machine or dispenser, they are placed directly over the crack, and a non-sag, fast setting epoxy paste is built up around the port to ensure a proper seal that can hold pressure.

Epoxy Injection Port – Industry Standard Bestseller

Durable plastic design surface mounted port. Tri-Base design with perforation holes for best possible adhesion. .

Dispenser: SealBoss P3003 Epoxy Pump

Having completed the preparation phase, the SealBoss P3003 Epoxy Injection Pump is effectively engaged as the device for dispensing the epoxy. This allows for the precise injection of the epoxy resin into the existing cracks through the strategically placed ports. The process starts at the lowest port on a vertical crack or the first port on a horizontal crack. Epoxy is injected until it begins to appear at the next port, signifying that the section of the crack between the ports has been filled. The injection process then proceeds to the next port, repeating the process until the entire crack has been repaired.

Once the epoxy has cured, the ports and the surface seal are removed. The result is a structurally sound bumper wall, restored to its original strength and durability.

- Versatile,

- Pumps Epoxy & PU Resin

- Electric Drill Operated

- Dual Piston System

- 5000 psi

- 2 Comp.

- Ratio: 2:1 standard, 1:1 custom

Versatile Applications Beyond Vehicular Barrier Walls

Although this article focuses specifically on vehicular barrier walls, the SealBoss epoxy injection system is highly versatile and applicable to numerous concrete repair scenarios, including:

- Parking decks

- Concrete beams and columns

- Basement and foundation walls

- Retaining walls and infrastructure

- Bridges and transportation structures

Why Choose SealBoss Epoxy Injection Systems?

SealBoss products and systems are trusted by industry professionals for their reliability and effectiveness:

- Robust performance backed by years of industry use

- Easy installation with detailed technical documentation

- Dedicated technical support to assist with challenging applications

Conclusion

Utilizing the SealBoss P3003 Epoxy Injection Pump combined with SealBoss Surface Mounted Tri-Base Ports delivers a comprehensive, effective, and lasting solution for repairing cracks in vehicular barrier walls and bumper walls. Epoxy injection methods significantly enhance structural integrity, extend the service life of concrete structures, and prevent further damage and deterioration.

For successful crack repair and structural restoration, always consult professionals experienced in epoxy injection systems.

Additional SealBoss Surface Ports and Epoxy Pumps

Epoxy Injection Corner Port

Durable plastic design corner surface port suitable for epoxy injections. Corner base design with perforation holes for best possible adhesion.

Epoxy Injection Drill Hole Mount Port

Durable plastic port designed to fit 1/2″ drill hole for higher injection pressures than regular surface ports.

- Top of the Line – Professional Use

- Pumps Epoxy & PU resin

- Pneumatic

- 850 psi

- 2 Comp.

- Ratio: 2:1 Standard, 1:1 custom

- Top of the Line – Professional Use

- Pumps Epoxy & PU resin

- Pneumatic

- 1000 psi

- 2 Comp.

- Ratio: 2:1 Standard, 1:1 custom

SealBoss Epoxy Injection System

Related Articles