Tunnel Segment Injection Repair

Chemical Grouts - Swell Tape Profiles - Swell Caulk Mastic

Mock-up Repair of a Tunnel Segment Using Polyurethane Foam Injection

Introduction

Within the intricate domain of tunnel leak sealing, polyurethane foam injection stands out for its effectiveness in tackling cracks and leaks.

This case study of a mock-up repair delves into the practical application of this method, exploring how a single tunnel segment was successfully leak seal injected with SealBoss 1510 water stop leak seal foam using specialized equipment.

Objective – Tunnel Segment Injection Repair

To seal a crack in its entirety and to its full depth, in a single tunnel segment, using polyurethane foam injection.

Methodology

Problem Identification

A prominent crack was identified in the tunnel segment, making it a prime candidate for repair. To simulate real-world scenarios, the crack was pre-injected with water to mimic a leak.

Equipment & Material Selection

Pump

SealBoss P2002 Injection Pump, known for its reliability and efficacy in such repair scenarios. The SealBoss P2002 Polyurethane Injection Pump boasts a compact design with an integrated stand. Remarkably lightweight yet powerful, it is compatible with most SealBoss® polyurethane products with viscosities between 10 and 1000 cps. This professional-grade pump offers outstanding output and pressure. Its modular design ensures low maintenance and easy cleaning.

Injection Packer

The SealBoss Evolution Long Aluminum Packer was chosen, a leading choice for deep, angled injections. or a successful injection process, mechanical injection packers and ports are crucial. Our extensive stock is curated to cater to diverse client needs, promising timely deliveries.

Foam

SealBoss 1510 Water Stop Leak Seal Foam, recognized for its water-stopping capabilities. SealBoss 1510, commonly referred to as 1510 Water Stop Foam, stands out as our premier and best-selling grout for addressing water leaks in a majority of crack injection contexts. When combined with 15x Accelerator, this hydrophobic, water-activated grout transforms into a foam seal based on MDI polyurethane. Furthermore, this resin is entirely solvent-free and composed of 100% solids.

Injection Strategy

A singular injection packer was placed at a precise angle towards the crack. This strategic positioning was critical to ensuring the foam could reach the full depth of the crack and seal it effectively.

Execution

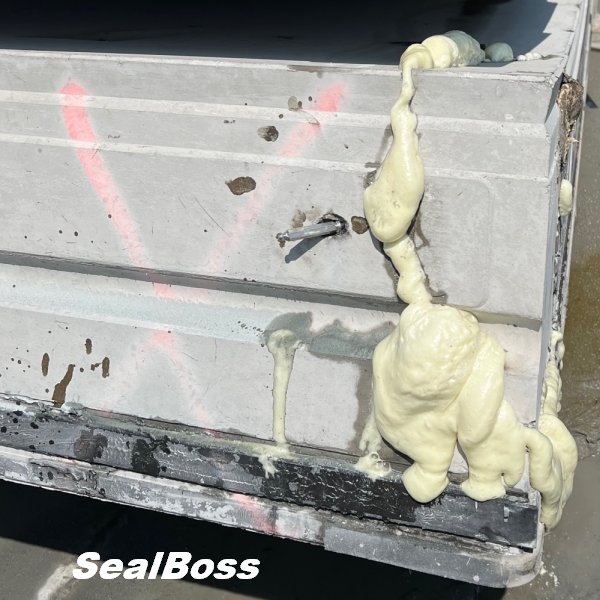

With the equipment set and the crack prepped, the SealBoss 1510 foam was injected using the SealBoss P2002 pump through the SealBoss Evolution packer. The foam’s expansive properties, coupled with the angled placement of the injection packer, ensured the material filled the entire crack from depth to surface.

Outcome – Tunnel Segment Injection Repair

Upon completion of the injection process, a thorough inspection was conducted to verify the effectiveness of the repair. The results were clear – the crack had been sealed entirely, with complete, uninterrupted foam penetration along the perimeter.

Key Learnings

Strategic Packer Placement

The success of this repair underscored the importance of correctly positioning the injection packer. An angled approach ensured the foam covered the crack’s entire depth.

Reliable Equipment

The SealBoss P2002 injection pump and SealBoss Evolution packer proved indispensable, delivering the foam efficiently to the target site.

Efficacy of SealBoss 1510

This particular foam showcased its prowess in stopping water ingress, highlighting its potential as a top-tier solution for tunnel repairs.

Conclusion

This case study stands as a testament to the efficacy of polyurethane foam injections in tunnel repair scenarios. When executed with precision and the right equipment, even a single injection point can address extensive cracks, ensuring the longevity and safety of critical infrastructure like tunnels.

Tunnel Segment Injection Repair and other SealBoss Tunnel Sealing Solutions

- Chemical Grouts

- Epoxy System

- Joint Seal Systems Overview

- Swell Tape – Swelling Rubber Profile Strips

- Swell Caulk – Hydrophilic Swelling Mastic

Tunnel Injection Repair Equipment

Leak-Seal Foam Grout

Water Stop Foam Grout

Hydrophobic Injection Foam Grout

Our #1 Selling Polyurethane Injection Foam

Water Cut-Off Injection Grout

Unregulated for transport. Drinking Water Contact meets NSF/ANSI 61 Section 5 requirements. 1510 PU Foam & Oakum Pipe Plug Kit