SealBoss Curtain Injection

Bladder / Curtain Injection – Curtain Wall Grouting Method

Introduction

Bladder or Curtain Injection is a specialized method used to seal below-grade block and concrete wall structures by forming a protective membrane through the permeation and consolidation capabilities of hydrophilic and hydrophobic grouts. Utilizing the SealBoss Leak Sealing Cube for training, contractors gain an intricate understanding of the injection process and grout behavior. This hands-on approach, which allows observation of the process from the soil side of the wall, prepares professionals for effective on-site applications, ensuring thorough and lasting waterproofing solutions.

Curtain Injection Injection Training with a SealBoss Leak Sealing Cube

The primary objective of the curtain injection method is to effectively seal below-grade block and concrete wall structures by leveraging the advanced membrane-forming, permeation, and consolidation capabilities of hydrophilic and hydrophobic injection grouts. This process ensures long-lasting waterproofing, even under challenging conditions where traditional methods may fail.

This specific training for curtain injection is conducted using the SealBoss Leak Sealing Cube, a sophisticated version of our mock-up designed to replicate real-world scenarios. The Cube offers contractors and engineers a detailed insight into the intricacies of the injection process and the dynamic behavior of chemical grouts under varying conditions. Equipped with Plexiglas cross-sections, the Cube allows trainees to observe the injection process from the ‘other side’—a perspective typically hidden during actual on-site curtain grouting. This unique visual aid is invaluable in understanding how the grout permeates and consolidates within the substrate, forming an effective waterproof membrane.

By closely following the grout’s interaction with the positive soil-side behind the wall, trainees develop a comprehensive understanding of the injection method and technology. This hands-on experience is critical for mastering the application of these advanced materials, ensuring successful outcomes in both routine and complex waterproofing projects. The ability to visualize and understand these processes in a controlled environment prepares professionals for the challenges they will face on the job site, ultimately leading to more effective and reliable sealing solutions in the field.

Procedure Outline

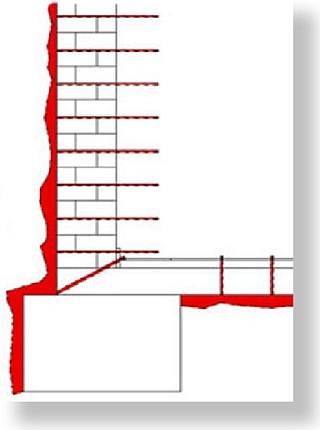

Identify the water source and pattern of moisture intrusion. Most block, stone, and brick leaks are caused by failed positive side membranes. Block walls are often unfilled which also creates voids and pockets for water intrusion. Drill Grid Pattern Drill 3/8 or 1/2 inch holes along the water marks at 2 feet intervals. Moving up the wall, continue to space the holes at 2 feet intervals creating a grid pattern of injection holes as seen in the image. These drill holes are to penetrate the substrate at full depth creating a channel in the wall through which chemicals can be injected.

Packer Install

Once the grid pattern is created, mechanical packers may be inserted into each one. In the case of block walls that are not filled adequately, longer packers are recommended providing a full length channel which ensures that material reached the back side of the wall. it is not recommended to simply fill the blocks with materials – block wall curtain injections require material travel through the entire wall. In the case of older and disturbed stone or brick structures, however, it is also common to inject the structure itself as seen to the right.

For high volume applications, Plastic Button Head Packers are available.

Injection Products and Pumps

In today’s focus, we highlight the SealBoss ® 1510 Curtain Injection Foam and SealBoss ® 15X Accelerator. The single component SB 1510 chemical injection grout is catalyzed with SB 15X Accelerator at variable percentages to either create low foaming expansion or high foaming expansion properties, with the accelerator dosage varying between 2 % to 25 %.

epending on site-specific needs, a selection of products is available, including the hydrophobic SealBoss 1510 / 1570 Foam, SealBoss FlexGel hydrophilic polyurethane gel, or SealBoss® 2400 SLV acrylic gel, are available.

Application Considerations

Because backfill and soil consolidation behind the structures are often unknown, applicators must monitor flow rates and material consumption closely.

Given the often unpredictable nature of backfill and soil consolidation behind structural walls, it is imperative for applicators to closely monitor flow rates and material consumption. In cases where significant voids are expected, the use of expansive hydrophobic polyurethane grout, such as SealBoss® 1510 Water Stop Foam, is recommended. This approach effectively fills large voids, creating a solid mass that can serve as a stable foundation for subsequent hydrophilic gel injections if necessary.

The Stage Grouting Technique

The stage grouting technique is often recommended in such situations. This method involves injecting the product in measured stages with reduced volumes. Each stage is given adequate time to react and form a natural barrier, prior to injecting the next grout stage. This strategic layering and controlled application enhances the overall effectiveness of the grouting process, ensuring comprehensive coverage of product along the outside of the wall and optimal stability.

For in depth training training on specific injection techniques or on-site assistance, please reach out to your SealBoss® Technical Representative or contact the main office at 714-662-4445 for further support.

Links