Leak Sealing Methods

Leak Repair Overview

Leak Sealing Methods

Introduction

This guide focuses on injection-based leak sealing for concrete and masonry—cracks, cold joints, tie-holes, penetrations, honeycombs, and construction joints. It consolidates common leak sealing methods used by contractors and facility teams: polyurethane injection, acrylate gel injection, curtain injection, oakum + PU, and epoxy injection.

The emphasis is on negative‑side access, active leaks, and rapid water shutoff.

Typical applications: basements, elevator pits, utility vaults, manholes, tunnels, parking structures, water/wastewater tanks, culverts, shotcrete, and blind‑side conditions.

The most common methods are: crack/joint injection and curtain grouting, which are essential for maintaining the structural integrity of concrete structures including tunnels, dams, commercial buildings, and foundations in general.

The article also explores other leak sealing methods and options like epoxy resin injection and swellable waterstop caulking and water activated, expanding polymer strip tapes, discussing their applications and effectiveness.

Ensuring Integrity in Concrete Structures

Water leaks in concrete structures can pose significant challenges, necessitating a thorough exploration of leak sealing methods. The integrity of structures like tunnels, dams, and foundations depends on the effectiveness of these methods. This article delves into the various techniques available, their applications, and the factors influencing their selection.

Water Stop and Leak Sealing with Crack/Joint Injection and Curtain Grouting Systems

Crack/joint injection and curtain grouting stand out as the most prevalent techniques for addressing active water leaks in concrete structures. These leak sealing methods are the first line of defense against water intrusion, providing immediate solutions to maintain structural integrity.

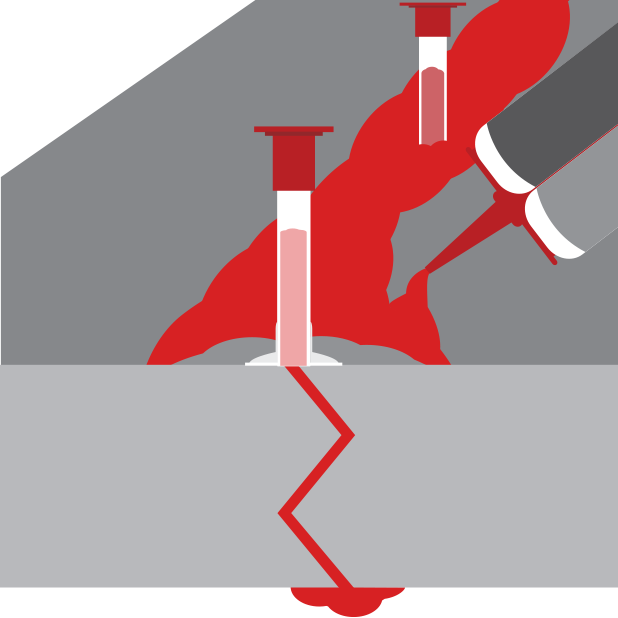

Polyurethane Injection

Best for: Active leaks, damp cracks, joints, tie‑holes, penetrations, negative‑side access.

How it works: Water‑reactive PU expands to fill the leak path and forms a closed‑cell barrier.

Hydrophobic vs hydrophilic: hydrophobic = fast stop and dimensional stability; hydrophilic = re‑swelling in cyclic wet/dry joints.

Pros: Stops water, works in wet environments, fast, minimal downtime.

Cons: Not many cons, not a structural repair. For structural repair use SealBoss Epoxy

SealBoss examples: 1510 Water Stop Foam (use with 15X Accelerator), 1570 / 1570 LV Water Stop Foams, FlexGel (hydrophilic), R70 pump flush.

See also: Concrete Leak Sealing with Polyurethane Water Stop Foam 1510 | 1570.

Oakum + PU Combination

Use for: Larger joints/voids, pipe penetrations, tie‑holes.

Method: Pack oil‑free oakum pre‑saturated with PU; mist to activate; lock with follow‑up point injections.

Best for: Ultra fine cracks, and curtain grouting behind structures.

How it works: Ultra‑low viscosity gel with adjustable set time migrates into fine capillaries; forms an elastic, water‑reactive gel.

Pros: Penetrates very fine paths; tunable gel time.

Cons: Not structural; requires proportioning accuracy and specialized injection equipment.

SealBoss examples: 2400 SealGel SLV Acrylate Gel; FlexGel for curtain injection.

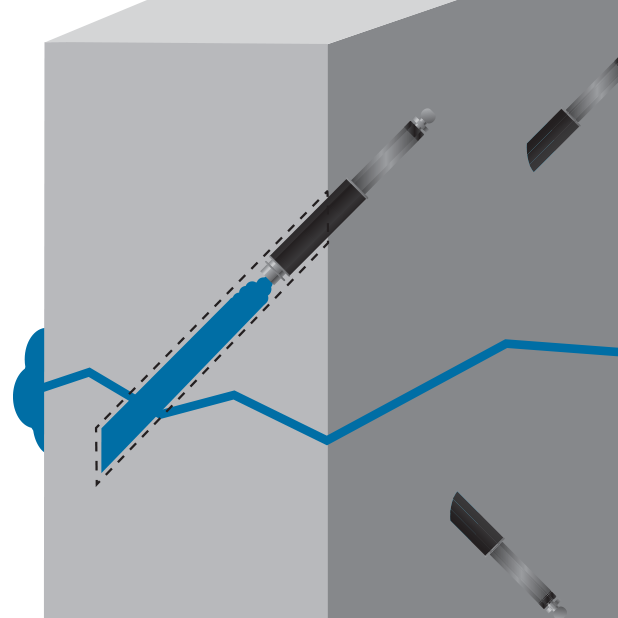

Crack/joint injection is a precise method that involves injecting polyurethane grout into specific cracks or joints where water is actively leaking. This technique is renowned for its effectiveness in sealing everything from minor seepage to significant leaks across various concrete structures, including walls, foundations, and commercial parking structures.

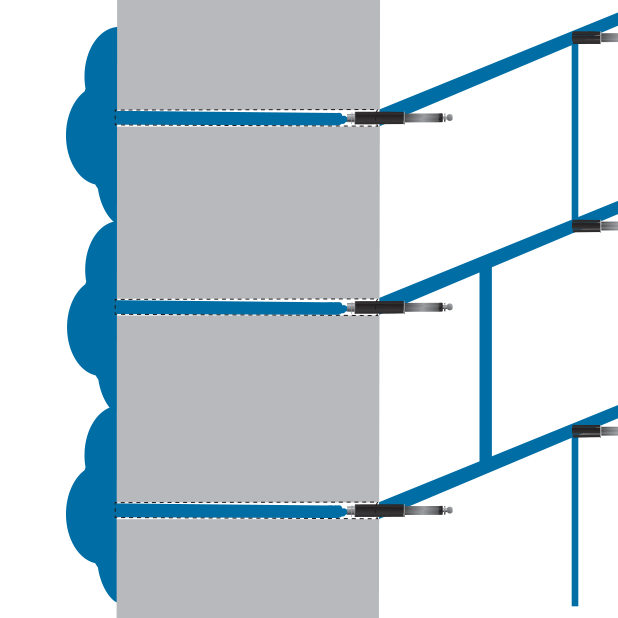

Curtain Grouting – Creating Barriers Against Water Intrusion

For larger leaks or when the precise leak location is elusive, curtain grouting is the method of choice. This leak sealing method involves injecting grout in a pattern that forms a waterproof barrier, particularly behind tunnel linings, offering a robust solution to water ingress.

- When to use

Water is entering from an unknown path or across a larger area and positive‑side access is not available. Curtain grouting creates an injected barrier behind the structure to block groundwater. PU or acrylate gels are commonly used depending on flexibility and set‑time needs. - Notes

Drill in a grid or fan pattern; low pressures and overlapping bulbs ensure coverage. Monitor take rates and returns.

Structural Repairs with Epoxy Injection Systems

Epoxy Resin Injection – Strengthening and Sealing Combined

While epoxy injection is primarily used for structural repairs, it also serves as an effective barrier against water intrusion. However, its use as a water stop is limited in areas with very active leaks.

Epoxy resins, synthetic polymers known for their strong adhesive properties, are particularly useful for sealing leaks in a variety of structures. Their ability to bond with concrete, some metals, and wood makes them a versatile option in the leak sealing methods arsenal.

Epoxy Injection – Structural Bonding

Best for: Dry, non‑moving structural cracks after water is controlled.

How it works: Low‑viscosity epoxy bonds crack faces to restore monolithic behavior.

Important: Stop water first (often with PU), then dry out before epoxy.

SealBoss example: 4040 LV, 4050 SLV Epoxy, low‑viscosity structural injection resins.

Construction and Cold Joint Systems

Swellable Waterstops – Expanding the Fight Against Leaks

Swellable waterstops are hydrophilic materials that expand upon contact with water, effectively sealing off leaks. These are commonly implemented in construction joints and are highly effective in segmented concrete tunnels and structures.

Questions & Answers

- What is the fastest way to stop an active water leak?

Polyurethane (PU) water‑stop injection using mechanical packers. Start at the tight end, vent through the next port, and stage re‑injections.

- When should I use curtain injection?

When the leak path is unknown/widespread or on large blind‑side conditions. Build an overlapping curtain (PU or acrylate) behind the structure via a grid pattern. - Can I inject from the negative side (inside)?

Yes. This is the major advantage of injection technology. PU and acrylate gels are routinely injected from the inside when the positive side isn’t accessible. - What packer spacing should I plan for?

Typically 6–12 in (150–300 mm), tighter for thin and hairline cracks or very high water flow. - Is injection suitable for potable water structures?

Yes—use SealBoss products with the appropriate drinking‑water certification. - Does injection relieve hydrostatic pressure?

No. Injection blocks leak paths; it doesn’t lower groundwater pressure. Include drainage/relief if needed. - Is epoxy injection recommended for active leak repair?

No. Epoxy is for structural crack repair. Stop water with PU injection systems; use epoxy if strength restoration is required and preferably in a dry environment.

Troubleshooting & Quality Checks

- Leak persists at a few points

Add ports between existing ones; lengthen gel time; re‑inject from tight end. - Resin blow‑by

Reduce pressure; confirm packer seating; replace coupler. - Backflow without travel

Inject at the next port; redrill packer hole; place new packer in proximity to the “dead” hole packer. - Recurring leak after dry‑out

Consider low viscosity hydrophobic or hydrophilic PU resin (or – in rare niche situations, acrylate gel) to reinject through newly installed packers; for unknown water paths paths, curtain injection may be advised. - Structural cracks after leak stop

Only in cases of structural repair requirements, perform epoxy injection.

Conclusion

Leak sealing methods extend beyond crack/joint injection and curtain grouting. A comprehensive understanding of material compatibility, leak severity, and environmental impact is essential in selecting the appropriate method. By considering these factors and the outlined criteria, stakeholders can make informed decisions that offer long-term benefits, ensuring the safety and longevity of concrete structures.

Related Articles