What is an Injection Tube?

Injection Tube Systems, also known as Injection Hose Systems, are essential tools used to seal structural and cold joints in below-grade concrete structures like tunnels, tanks, and parking garages. These systems play a critical role in maintaining the integrity of concrete constructions by preventing water infiltration.

Cold joints form when new concrete is poured against existing cured concrete, creating seams that can become pathways for water migration under hydrostatic pressure. If left untreated, this water infiltration can lead to concrete deterioration, rebar corrosion, and significant infrastructure damage.

The SealBoss Injection Tube functions as an efficient delivery system for injection resins and grouts. It channels these sealing materials directly into concrete joints, cracks, voids, and honeycombs, effectively sealing potential leak paths. By proactively addressing these vulnerabilities, Injection Tube Systems help extend the lifespan of concrete structures and protect them from water-induced damage.

Watertight Confidence with SealBoss

— Protecting Concrete from the Inside Out —

SealBoss Injection Tube Type 2: Advanced Solution for Sealing Concrete Cold Joints

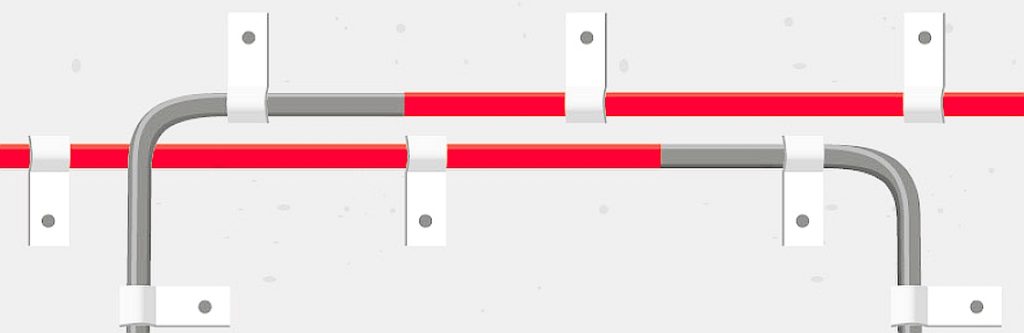

The SealBoss Injection Tube Type 2 is an innovative system designed to create watertight seals in cold joints of poured concrete structures. Constructed with a specially designed perforated plastic core tube and two independent woven membranes, this injection tube prevents the infiltration of concrete particles and contaminated water during and after the concrete pour.

Under pressure injection, the woven membranes ensure an even distribution of injection resin along the tube and into the cold joint.

The flexible nature of the Injection Tube Type 2 allows it to conform to uneven substrates and navigate corners, providing a comprehensive seal in complex structural layouts.

Understanding Cold Joints in Concrete

In concrete construction, each new pour onto existing cured concrete forms a cold joint—a point of low cohesion due to the lack of chemical bonding between the pours. These joints are vulnerable to water infiltration driven by hydrostatic pressure.

Additionally, concrete shrinkage introduces stress that can lead to cracking and erosion over time, exacerbated by fluctuations in weather and temperature.

The SealBoss Injection Tube Type 2 System: A Primary Water Stop Solution

By installing the SealBoss Injection Tube Type 2 as a primary water stop system and subsequently injecting it with SealBoss Resin, a monolithic seal is formed within the cold joint.

This process not only seals the joint but also penetrates fine cracks and fissures, effectively preventing future water migration and enhancing the structural integrity of the concrete.

Applications

- Cold Joints: Sealing joints between successive concrete pours.

- Expansion Joints: Accommodating structural movement while preventing water ingress.

- Structural Joints: Enhancing the durability of joints.

- Replacement for Traditional PVC Water Stop Systems: Offering a more effective and economical alternative.

- Primary Waterstop System: Serving as the first line of defense against water infiltration.

Advantages

- Economical Water Stop System: Cost-effective solution for sealing joints.

- Simple Installation: User-friendly setup reduces labor time and costs.

Compatibility with Various Injection Resins: Adaptable to different project requirements. - Creates a Monolithic Water Stop Seal: Ensures a continuous barrier against water.

- Suitable for Potable Water Applications: NSF-certified injection grout allows for safe use in drinking water structures.

- Effective on Honeycombed and Uneven Concrete Substrates: Adapts to imperfections in the concrete.

- Withstands High Concrete Weight: Durable under substantial loads.

- Injectable in Dry or Flowing Water Conditions: Versatile for various environmental scenarios.

- Good Chemical Resistance: Resilient against a variety of chemicals.

- Repeated Injections: Under certain conditions with use of acrylate gels possible.

Conclusion

The SealBoss Injection Tube Type 2 system is an essential product for creating watertight cold joints in poured concrete structures. Its advanced design and ease of installation make it a superior choice for professionals seeking reliable and long-lasting water stop solutions. By effectively sealing cold joints and accommodating structural complexities, it plays a critical role in preserving the integrity and longevity of concrete infrastructures.

Injection Tube / Injection Hose System Type 2 Water Stop

If you would like more information about our extensive range of injection equipment and accessories, please contact us at SealBoss. Our knowledgeable representatives are eager to assist you with any inquiries. We provide on-site support and training for all SealBoss System Solutions to ensure the success of your projects.

When you call, please ask for your technical sales representative—we are ready to help!